Managing inventory and ordering processes can be a complex and time-consuming task for manufacturing teams. From maintaining accurate inventory records to generating purchase orders (POs) and handling long lead time items, every step in the process must work seamlessly to ensure smooth operations. OpenBOM simplifies these workflows with powerful features designed to enhance procurement and inventory management efficiency.

In this blog, we introduce a series of use cases and tutorials that highlight how OpenBOM supports your inventory and ordering needs. Whether you’re defining vendors, managing long lead times, creating POs, or running production processes, OpenBOM provides the tools you need to stay organized and efficient.

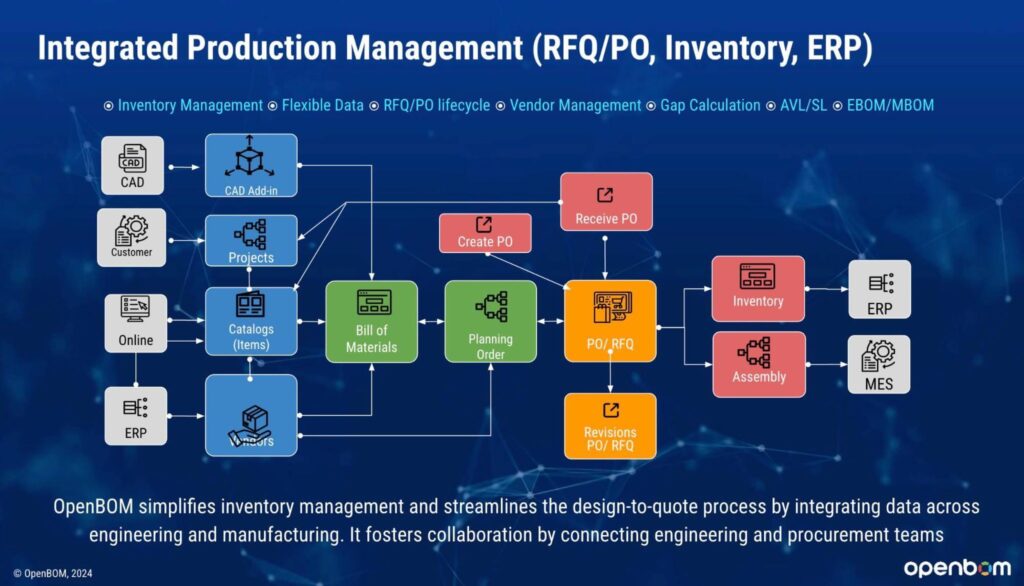

OpenBOM Inventory Planning Process in OpenBOM

There is a distinct process in OpenBOM that allows you to manage inventory, purchasing, generated RFQ/PO, and maintain the needed inventory level. The process is described in the picture below and includes typical phases: (1) Setting up vendors, (2) Order items from catalogs, (3) Order items and BOMs with the quantity for a package. (4) manage inventory and order BOMs.(5) Turn your inventory into production items.

Check the pics below:

1. Setting Up Vendors

One of the first steps in effective inventory management is setting up your vendors. In our video, “Inventory, RFQ POs – Setting Vendors,” we show you how to:

- Define vendors for streamlined RFQs and POs.

- Add and configure vendor details for your inventory.

- Import vendor lists to simplify setup and collaboration.

Watch the video:

2. Ordering Items with Long Lead Times

Managing items with long lead times is crucial for maintaining production schedules. In the video, “RFQ/POs and Inventory: Ordering Long Lead Times,” you’ll learn how to:

- Identify and manage items with extended lead times.

- Order these items directly from your catalog.

- Stay ahead of delays with proactive procurement.

Watch the video:

3. Ordering BOMs with Quantity Multipliers

Sometimes, you need to order components in specific quantities or batches. In “RFQ/POs and Inventory: Orders BOMs,” we demonstrate:

- How to create an order for a BOM with quantity multipliers.

- Managing bulk orders to align with production needs.

- Streamlining the process for RFQs and POs.

Watch the video:

4. Creating and Managing POs

Efficient purchase order creation is essential for maintaining a smooth supply chain. Our video, “Inventory, RFQ POs – PO Creation,” explains:

- Multiple methods to generate POs from different orders.

- How to export and send POs to vendors.

- Customizing and organizing POs for your workflow.

Watch the video about PO creation steps

5. Releasing to Production

Once POs are finalized, the next step is releasing items to production. In “RFQ/POs and Inventory: Release to Production,” you’ll learn how to:

- Export POs and manage vendor communication.

- Update inventory with received items.

- Initiate and run production (assembly) processes.

Watch the video on how to trigger production process.

6. Frequently Asked Questions (FAQ)

Finally, we’ve compiled tips, tricks, and best practices in “RFQ/POs and Inventory: FAQ.” This video provides:

- Solutions to common challenges in inventory and procurement.

- Practical advice for optimizing your workflows.

- Key insights to enhance your OpenBOM experience.

Watch the video with best practices and tools.

Why OpenBOM?

OpenBOM’s flexible and user-friendly platform empowers teams to manage procurement, inventory, and production with ease. OpenBOM’s unique differentiation lies in its integration of engineering processes with simple batch ordering, planning, and inventory control. The workflow supported by OpenBOM is ideal for engineering teams and SMB manufacturing organizations that need to manage prototype building, collaborate with contract manufacturers, and scale small batch production efficiently.

These how-to videos showcase practical solutions to everyday challenges, helping you save time, reduce errors, and stay ahead of your manufacturing demands.

Stay tuned for more OpenBOM tutorials and insights in our How-To Series. Ready to get started? Explore the videos to learn about OpenBOM’s inventory and ordering processes today!

REGISTER FOR FREE to start a trial.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.