Working with complex design structures, such as weldments, often presents challenges when it comes to creating a streamlined Engineering BOM process. Extracting accurate data from weldments and making it readily available for downstream business functions—such as supply chain and procurement—is critical for efficient operations. By simplifying this process, engineers can spend less time managing data, while procurement teams can reduce errors and make more informed decisions.

In this article, we introduce two must-watch videos from OpenBOM’s How-To Series that demonstrate the practical steps for managing SOLIDWORKS Weldments with OpenBOM. These videos not only simplify the process of integrating weldment data into Engineering BOMs but also highlight how similar functionalities are available for other CAD systems.

Video 1: How to Manage SOLIDWORKS Weldments in Engineering BOM

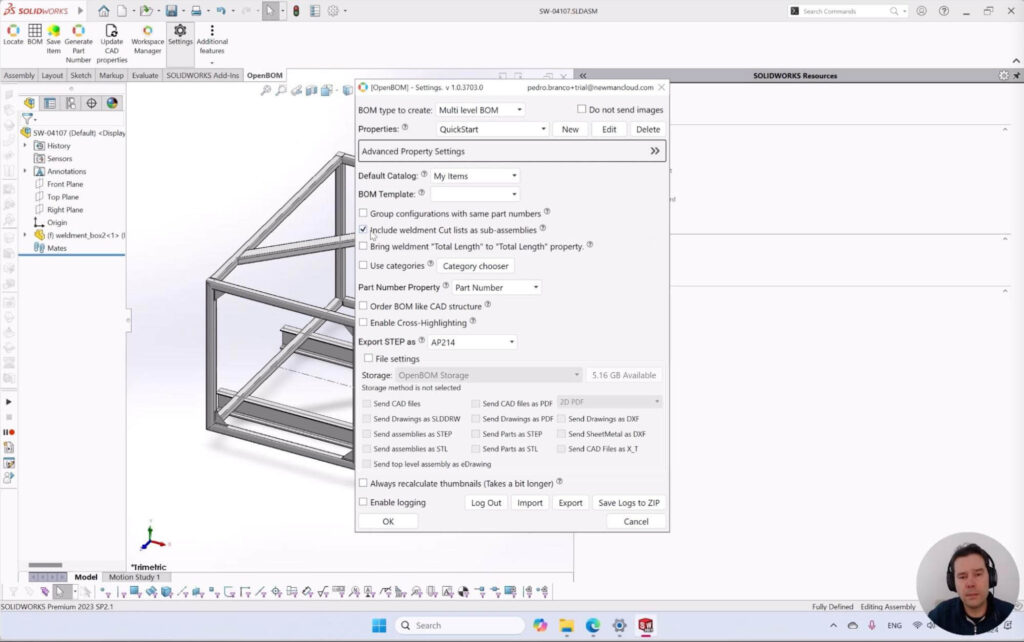

To configure OpenBOM with SOLIDWORKS weldment, use the option in the settings.

In the first video, we demonstrate how to:

- Capture SOLIDWORKS Weldments and roll up multiple weldment segments into a single BOM entry.

- Properly calculate the length of weldment materials to ensure precise data in the Engineering BOM.

- Configure essential OpenBOM settings in SOLIDWORKS for seamless integration.

- Set up Part Numbers for weldment materials to streamline the organization and procurement process.

This video is perfect for engineers looking to optimize their weldment data management process and ensure their Engineering BOMs are accurate and actionable.

📺 Watch video:

Video 2: SOLIDWORKS Weldments Total Length Calculations in Engineering BOM

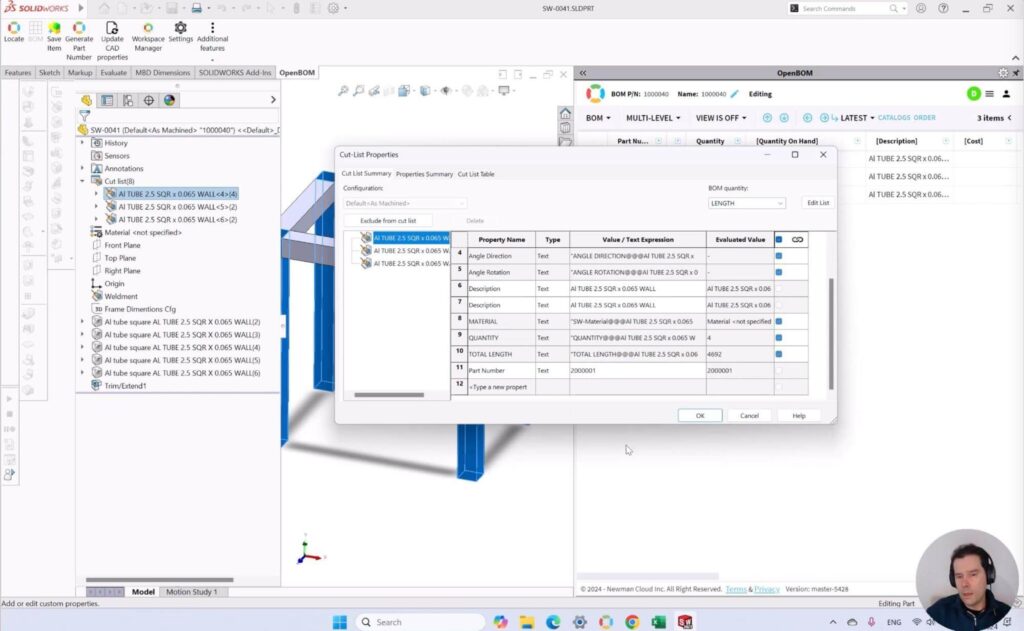

The second video focuses on leveraging the “Total Length” calculation feature in SOLIDWORKS Weldments and how to integrate this data into OpenBOM. You can configure weldments to extract total length.

Key topics covered include:

- Using “Total Length” calculations for weldments and transferring this data to the Engineering BOM.

- Choosing between two Quantity options: “Length” for precise material tracking or “Each (EA)” for unit-based calculations.

- Best practices for managing weldment materials to support both engineering and procurement workflows.

This video offers steps on how to configure and use OpenBOM with SOLIDWORKS weldment to help engineers streamline their BOM creation while providing procurement teams with the precise data they need for ordering materials.

📺 Watch video:

Why It Matters

Accurate and efficient weldment data management directly impacts the overall performance of engineering and procurement teams. By utilizing OpenBOM with SOLIDWORKS, you can:

- Reduce manual data entry and errors.

- Provide real-time, accurate BOM data to all stakeholders.

- Save time and resources, allowing your teams to focus on innovation and execution.

And the best part? These OpenBOM features are not limited to SOLIDWORKS; similar functionalities exist for other leading CAD systems, ensuring flexibility and scalability for your business needs.

Conclusion

OpenBOM simplifies the journey from design and engineering to procurement by bridging the gap between CAD systems and downstream business processes. By automating data capture, enhancing accuracy, and providing flexible BOM management tools, OpenBOM ensures that your teams can work smarter, not harder. From weldment calculations to streamlined workflows, OpenBOM empowers your organization to focus on innovation and growth while minimizing inefficiencies and errors.

Start leveraging OpenBOM today to transform your Engineering BOM processes into a seamless, end-to-end solution for your business. Watch these videos and see how OpenBOM can make a difference for your team.

REGISTER FOR FREE and check how OpenBOM can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.