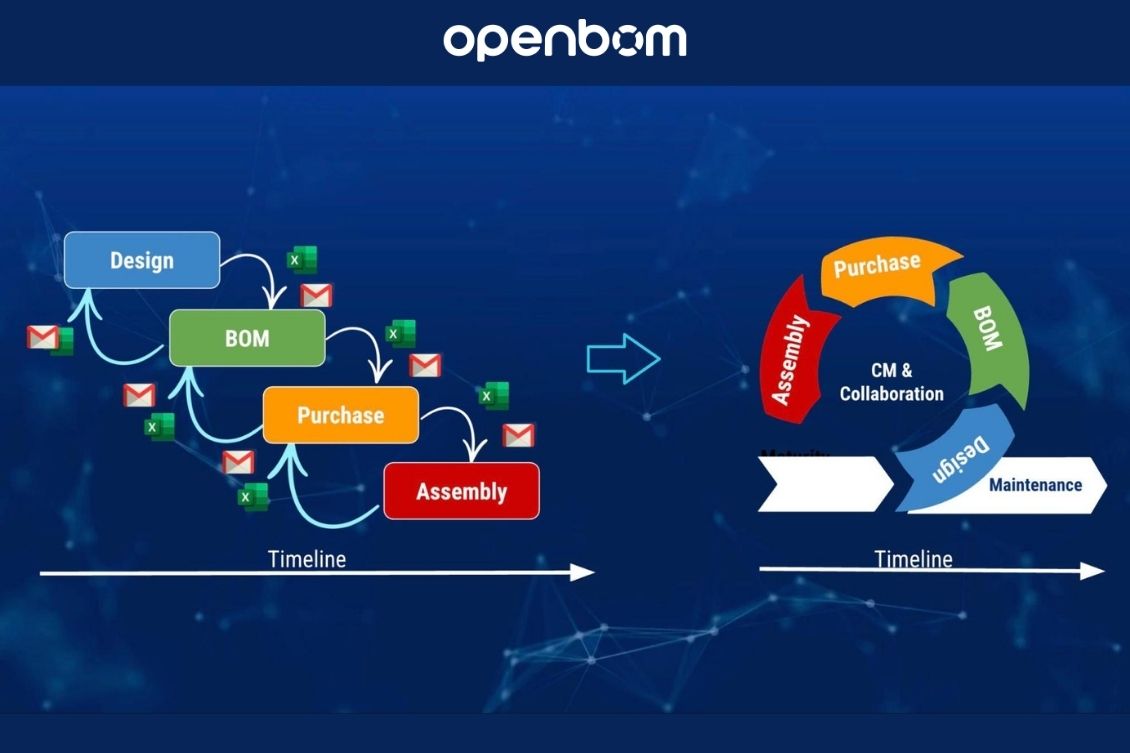

Providing seamless integration between engineering and business functions, such as production planning and procurement, is extremely important. When it is done using Excel and Emails, the outcome will be sub-optimal- you will lose time, make mistakes, and deliver late with the higher cost of the product. Therefore, to provide an informational system to support digital engineering and procurement is extremely important.

At our recent live demo, we walked through a complete Engineering to Procurement workflow using OpenBOM, showing how engineering teams, procurement managers, and manufacturers can stay in sync using a unified digital thread.

From Emails and Files to Connected CAD to Order Environment

OpenBOM organizes information and helps you to automatically make procurement planning, communicate with contractors, and suppliers. In this picture, you can see the overall process.

If you missed it, here’s your recap with all the highlights and key takeaways.

Watch the video of the webinar:

Engineering to Procurement Story

If you don’t have time or want to get a more descriptive story, check the notes below to get a basic understanding of how OpenBOM engineering to engineering-to-manufacturing and procurement process works.

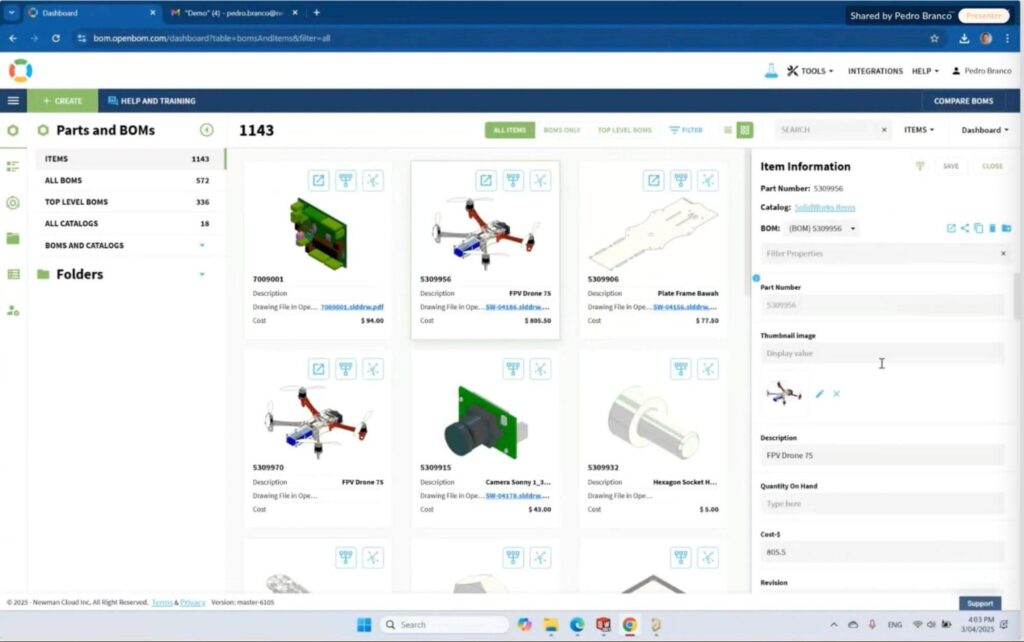

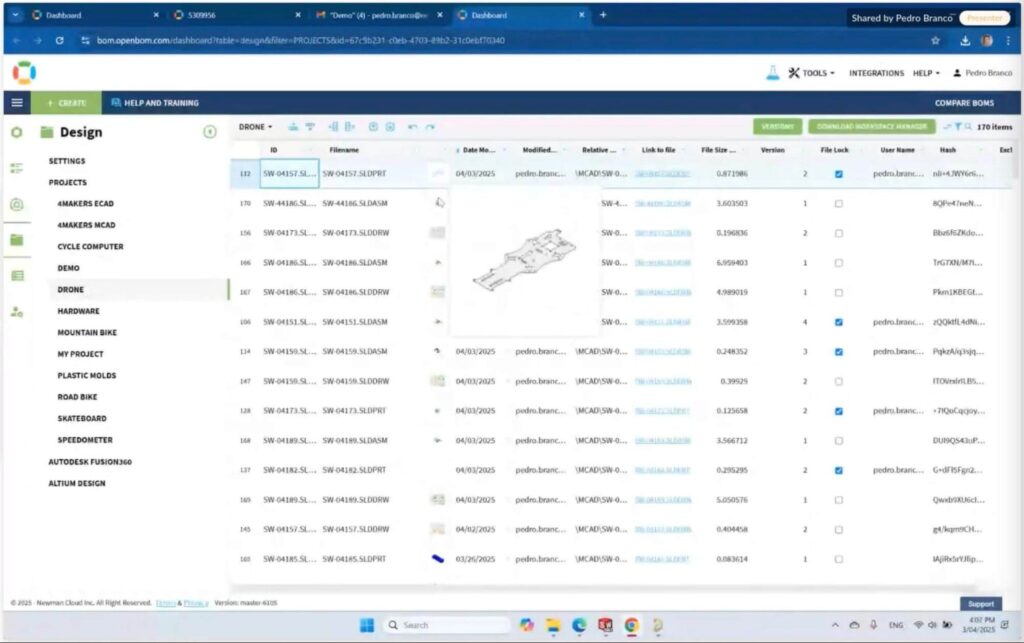

Centralized Data & Collaborative Workspace

We kicked things off by showcasing the OpenBOM Collaborative Workspace, where all engineering data lives. Whether you’re working in Solidworks, Altium, or another CAD system, OpenBOM provides a real-time data environment that supports simultaneous work and collaboration across roles and disciplines.

🔍 2. Seamless Navigation & Intuitive UI

OpenBOM’s search, navigation, and data access features were demonstrated live. Engineers could quickly find items, navigate complex product structures, and explore designs and components with ease. No training sessions, no lengthy onboarding—just a modern, intuitive interface.

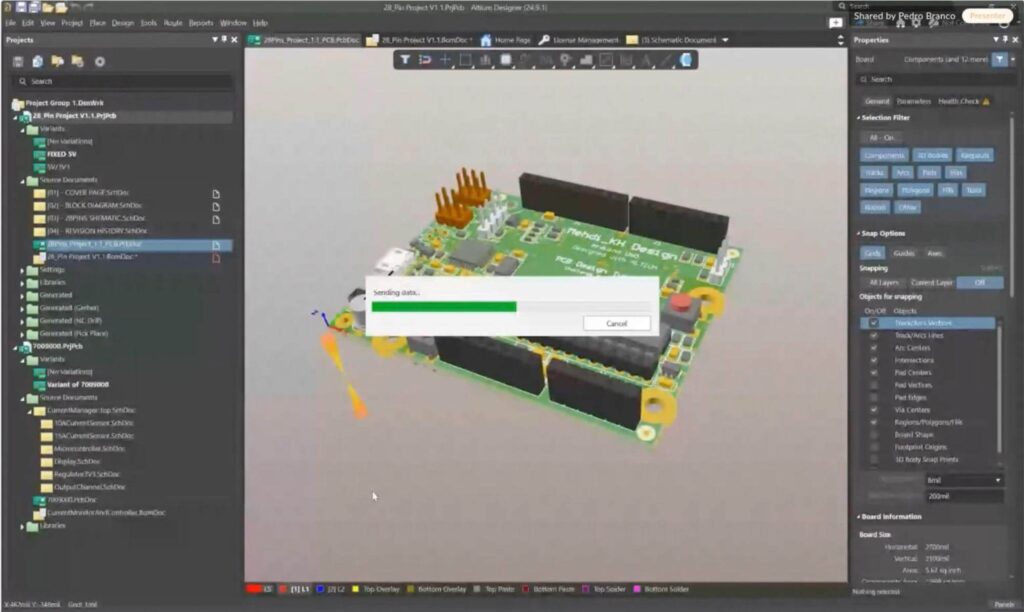

🛠️ 3. Multi-Disciplinary BOMs: Mechanical + Electronics

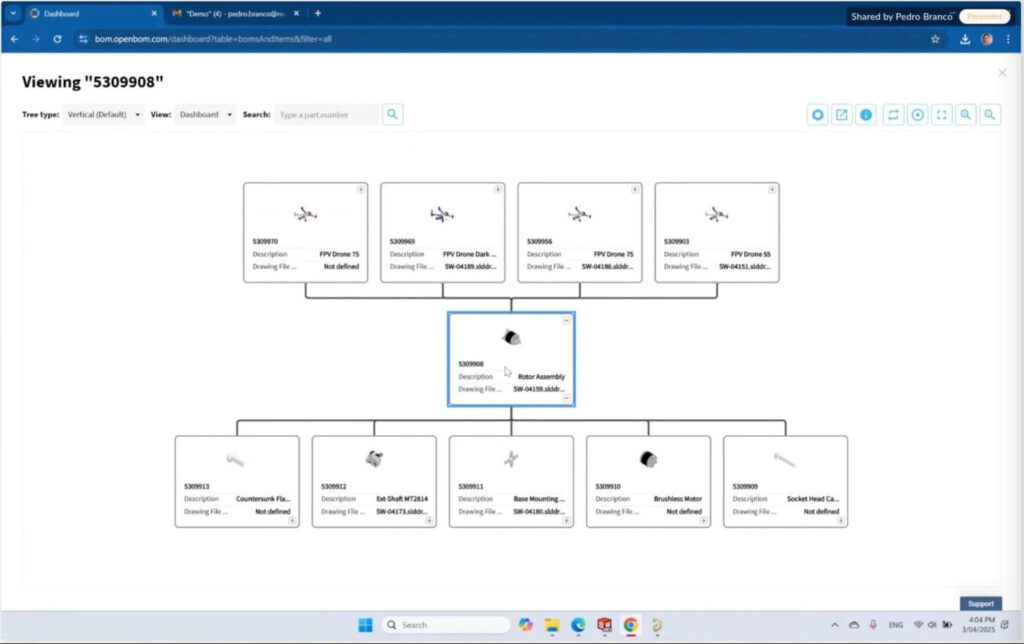

A standout moment was the demonstration of a multi-disciplinary BOM, combining mechanical parts from Solidworks with PCB assemblies from Altium. This holistic approach is essential for modern products that integrate hardware, electronics, and embedded systems.

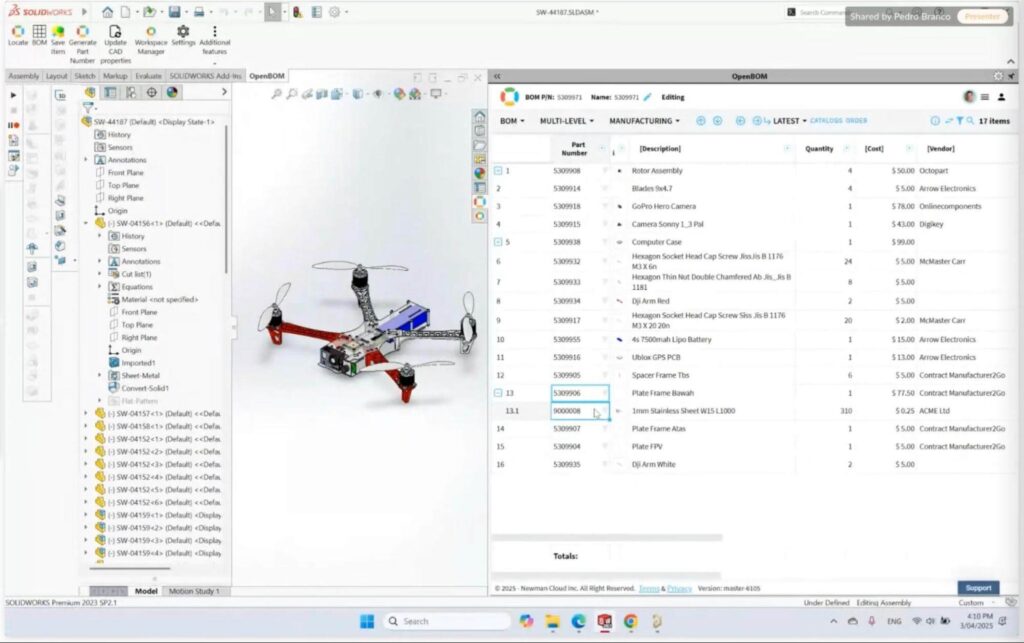

SOLIDWORKS in Action

Using OpenBOM for SOLIDWORKS, we showed how to extract product structure, CAD files, and metadata. The integration handles file locking, version management, and collaboration without users overwriting each other’s work—something traditional PDM systems often struggle with.

Managed File Locks & Version Control

A deep dive into OpenBOM’s PDM Collaborative Lock architecture demonstrated how changes are managed across CAD systems. Files are locked during editing, preventing conflicts, and version history is preserved, ensuring clarity in design workflows.

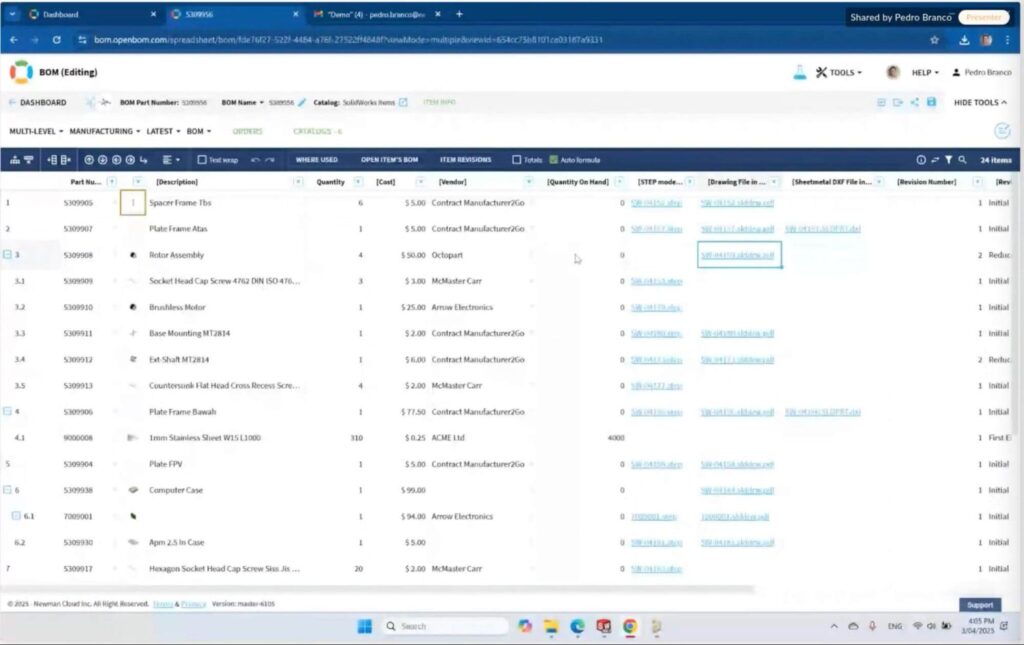

BOM Creation, File Derivatives & Structure Management

Once the design is complete, OpenBOM facilitates automatic BOM creation, complete with associated files (STEP, PDFs, Drawings). A structured product tree is built instantly, with support for multi-level hierarchies, custom properties, and CAD-derived metadata.

Organizing Data with Multiple Views

OpenBOM enables role-based views—engineering views, procurement views, manufacturing views—so each team sees just what they need. You can slice the BOM by lifecycle stage, vendor, or custom filters.

Real-Time Multi-User Collaboration

We saw how multiple users can edit the same BOM simultaneously, with changes reflected live. No check-in/check-out drama. Just real-time collaboration with full traceability and version history.

Electronic BOMs from Altium

Using OpenBOM for Altium, we demonstrated how to create a BOM for a PCB assembly. Metadata, part numbers, and supplier info were pulled in, aligned, and connected to the broader product structure seamlessly.

Design Approval → Procurement Flow

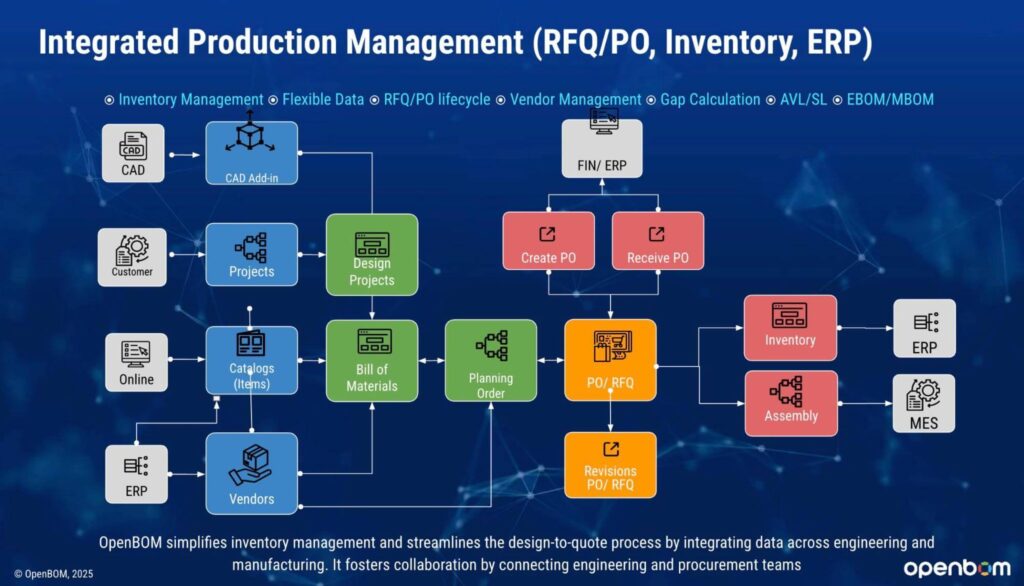

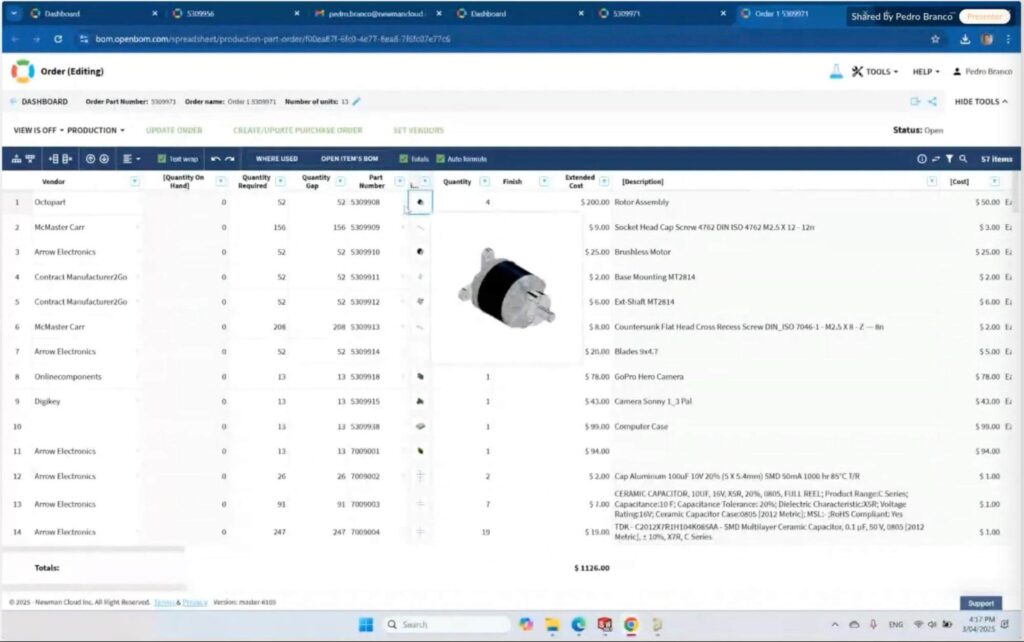

Once the BOM is finalized and approved, we shifted gears into procurement:

- Create orders for multiple units

- Automatically identify gaps between what’s designed and what needs to be purchased

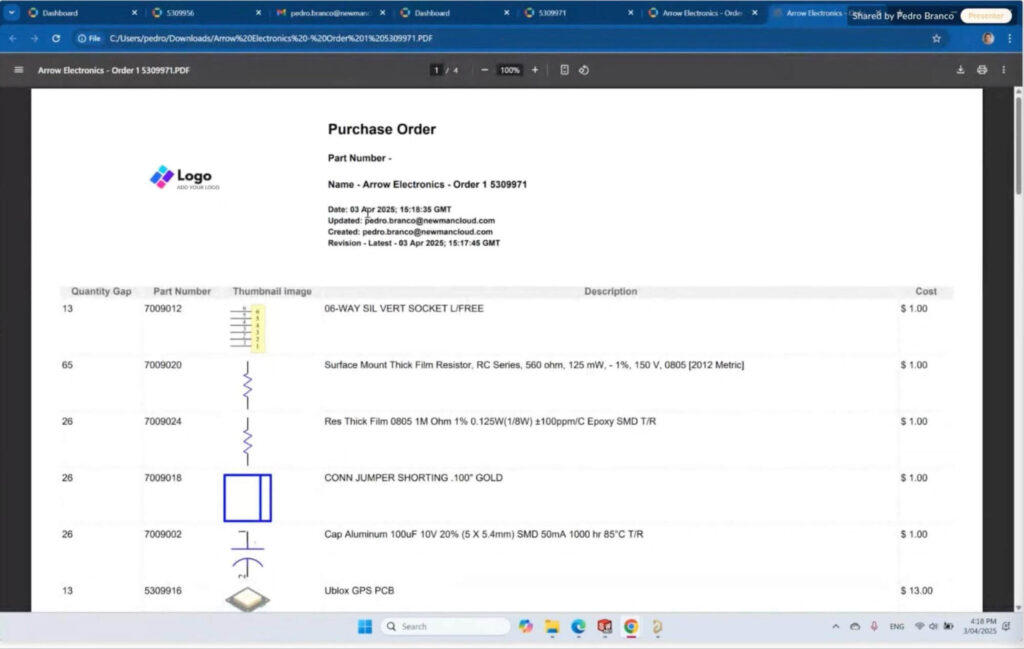

- Generate Purchase Orders (POs) for missing items

Rich PO Deliverables for Procurement

Each PO includes not only item info, but all supporting documents: STEP files, PDFs, datasheets, and more. Everything procurement teams need to place confident orders and communicate with suppliers is bundled and accessible.

Engineering Connected with Vendors

The big picture? OpenBOM connects engineering directly with the vendor ecosystem, eliminating friction and ensuring accurate, up-to-date information flows from design to purchasing to the shop floor.

💬 Q&A Highlights

Here are some great questions from the audience during the live session:

❓How do I define multiple vendors for a part?

OpenBOM supports multiple vendors per item with a preferred rank. You can also specify approved vendors and dynamically switch between sources during ordering.

❓Can I group orders for specific manufacturing batches?

Yes! OpenBOM lets you filter and group orders based on quantity, supplier, region, or any custom property—giving you complete control over how POs are generated.

❓What about file locking in Solidworks?

OpenBOM applies file-level locking inside Solidworks and other CAD tools. You can prevent simultaneous edits and configure lock settings specific to your team’s workflow.

❓How does OpenBOM handle release management?

Once a design is released, it can be frozen, locking the structure and associated files. No changes can be made unless explicitly revised or promoted to a new version.

❓Can I compare BOMs between engineering and procurement?

Absolutely! OpenBOM’s xBOM Compare function visually highlights differences between the original engineering BOM and the final procurement-ready version—giving everyone clarity and control.

Conclusion

This live demo was a great way to show how OpenBOM brings clarity, structure, and speed to the engineering-to-procurement journey. Whether you’re designing in Solidworks or Altium, managing multi-disciplinary BOMs, or handling complex sourcing workflows—OpenBOM connects it all.

👉 Want to see it in action? Start an instant FREE TRIAL and explore how OpenBOM can modernize your product lifecycle.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.