Timing is everything in the world. Think about the time we live now. The last few years brought so many changes in the world, the manufacturing industry, and the way companies are developing and manufacturing products. These years changed the way we live, work, and communicate. It disrupted entire industries and created multi-billion dollar opportunities and challenges. When we started OpenBOM a few years ago, we envisioned that digital transformation and new ways of data management and collaboration will be leading the way. However, it was hard to imagine the magnitude of changes. The challenges like supply chain shortages and other product development complexity is accelerating the changes in the processes to manage product information globally, collaborate with multiple contractors and suppliers, make supply chain risk assessment, find alternative sourcing with a shortage of resources and components.

BOM Management Problems

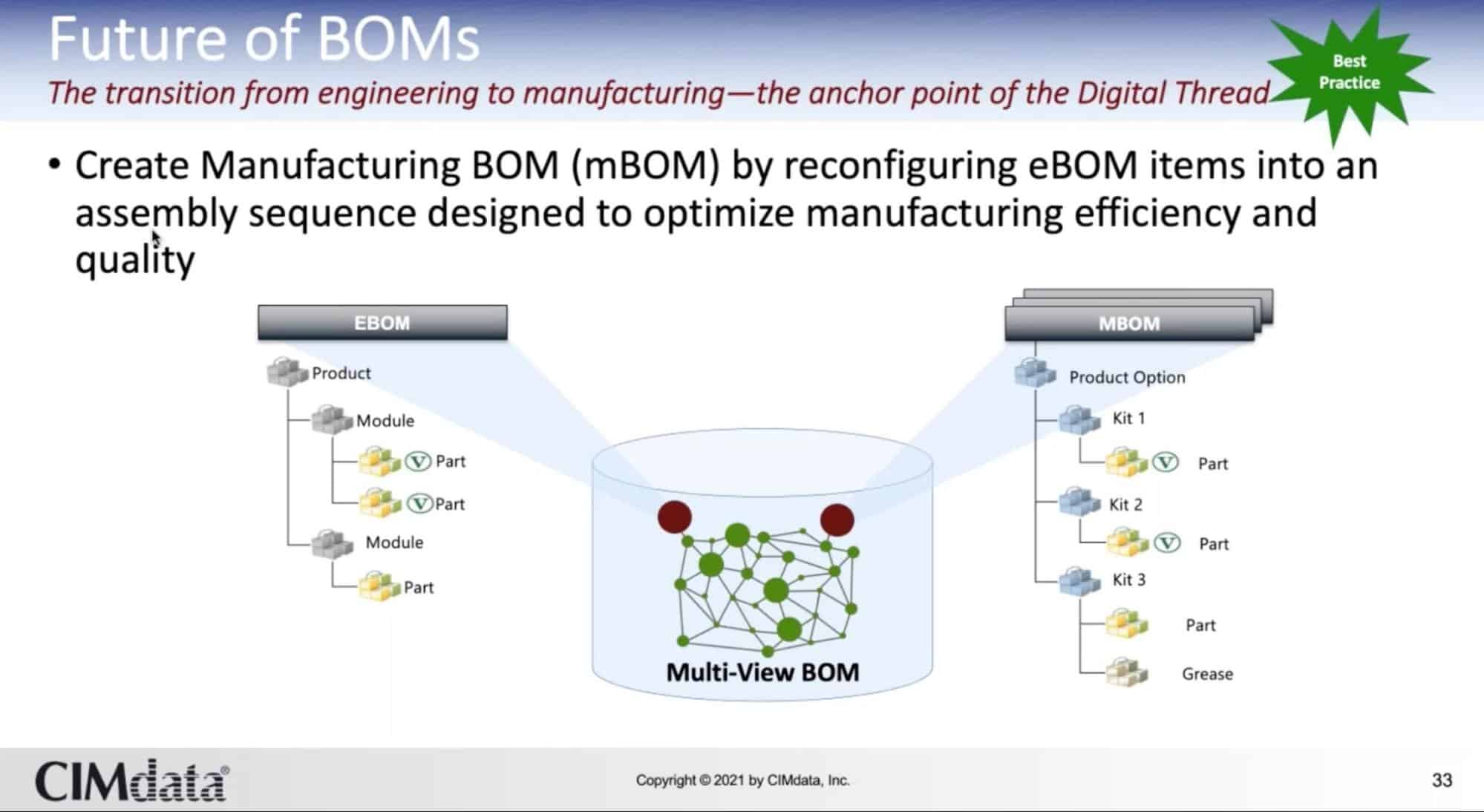

Bill of Materials management is a complex discipline that requires advanced data management techniques and approaches to control product data, structures, lifecycle representations and allow multiple people and companies to get access to this information in different periods of time. CIMdata webinar Why mBoM alone is not enough? John MacKrell, CIMdata chairman and long-time practitioner and advisor in PLM and related disciplines, discusses why an MBOM may serve some of the use cases, but fell short to provide a reliable business practice for modern manufacturing companies, especially since the complexity of products and processes is growing. The transformation needer in BOM management and PLM is emerging.

Multi-View BOM Management

In my article on Beyond PLM, I discussed what is multi-view BOM management and the advantages of such an approach to product structure management. This is how CIMdata defines the future of BOM management- multi-view BOM allowing reconfiguring eBOM items into an assembly sequence designed to optimize the manufacturing processes.

Such an approach is super resonating with what we’re building at OpenBOM and I wanted to share with you some details of the OpenBOM features, functions, processes, and data management architecture we created to support multi-view BOM principles.

Data Management Architecture

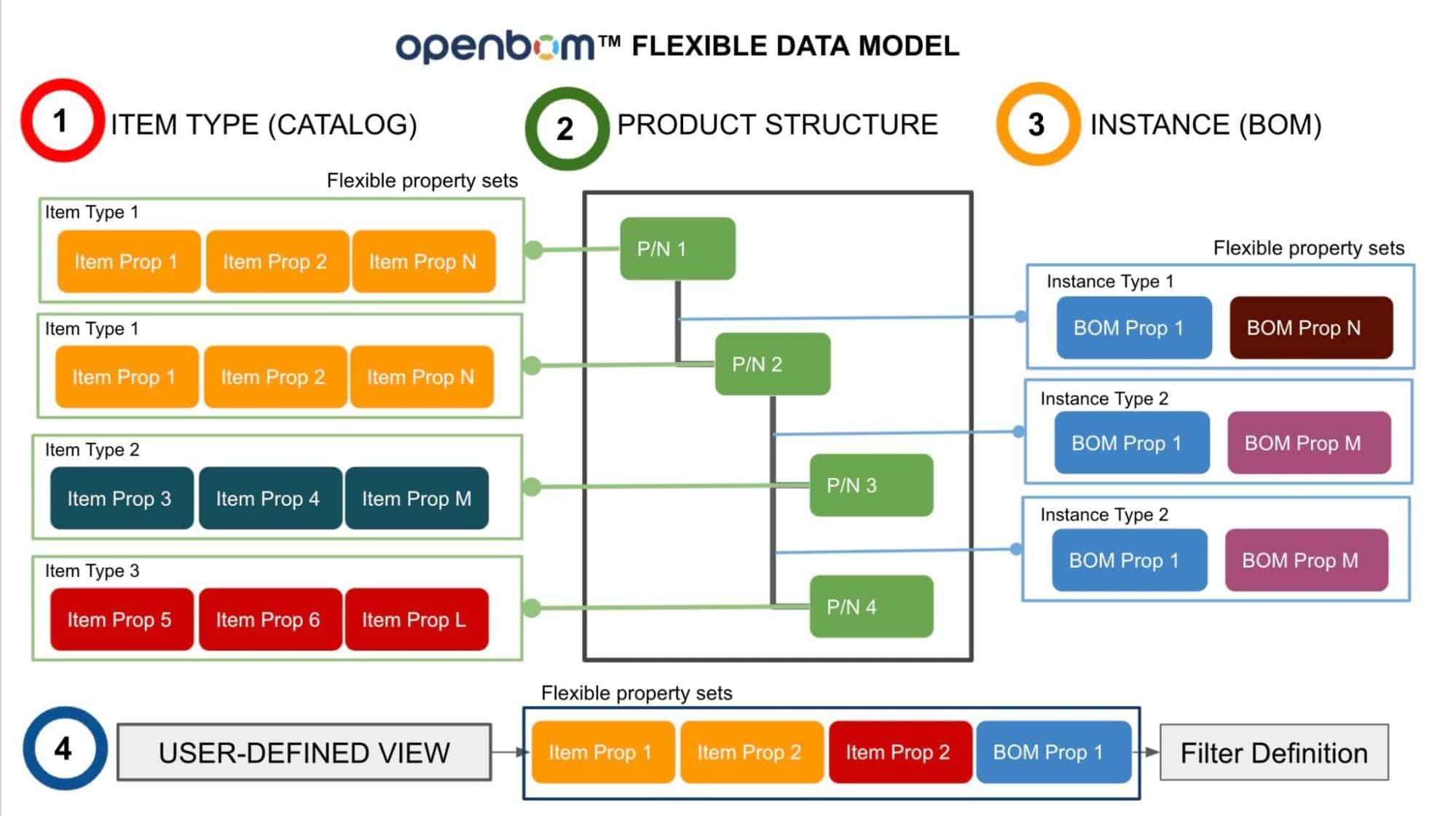

OpenBOM data management is using advanced polyglot persistence architecture using multiple databases to provide flexible data modeling capabilities, a rich set of features to manage single-level BOM, data sharing, and real-time collaboration combined with flexible BOM view architecture. OpenBOM is using Graph Databases technology (Neo4j) to support flexible multi-disciplinary relationships models for access control, item management, product structure, and revision control.

There are 3 fundamental relationship types supported by OpenBOM:

- Item Reference/Instance (connection item master and item instance)

- Product Structure (to create flexible data hierarchies)

- Item revisions (to create item master -revision associations)

Besides that, the OpenBOM user-defined views mechanism allows applying a structured lense to manage a subset of views on top of a generic product structure representing multiple BOM structures. To improve the robustness of the implementation, the OpenBOM BOM sync mechanism allows supporting 2 BOMs model (described by CIMdata in the webinar) in which EBOM and MBOM can be staying in sync.

OpenBOM Implementation and Use Cases

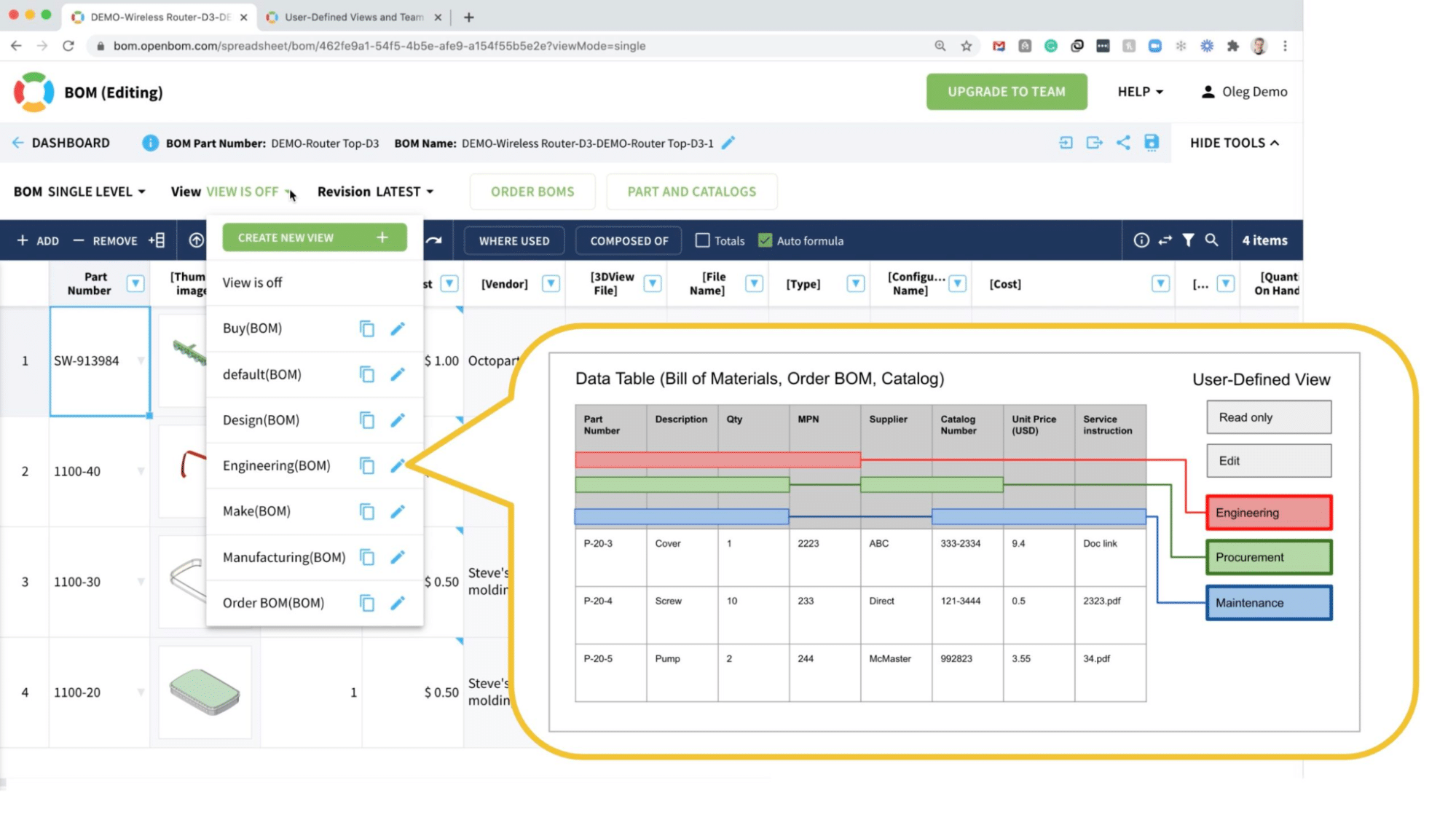

The multi-view data structure in OpenBOM is implemented using a “user-defined” view mechanism. The mechanism is a structured lens that allows filtering BOM structure by traversing graph relationships based on the data property criteria defined in the structure (on both item and instance properties). The following diagram shows the full set of OpenBOM data model implementation.

OpenBOM model implemented a diverse set of data processing tools starting from the design, providing CAD integrations to extract the engineering data, including part numbers and full multi-level data set, and making data accessible to all people in the organization.

The latter is simplifying communication and allows everyone in the company to share information and get access to the data via special role-based views (team views).

Next Steps in OpenBOM development

We are not done by any means. The foundational architecture of OpenBOM allows flexible item master and item instance management, flexible product structure, and view mechanism capable to show different structures for EBOM, MBOM, SBOM, and other xBOM models. Flexible and robust data management technology combined with multi-tenant data modeling provides a solid foundation for future improvements such as introducing advanced multi-view capabilities for:

- complex effectivity filters

- variants and configurations

- rule-based filters

- semantic attributes similarity

These and many other enhancements of OpenBOM data modeling will provide a more advanced mechanism to manage multiple views of product data. A rich semantic data layer allows you to create modeling for complex products in the industries such as aerospace, automotive and complex machinery. At the same time, the initial simplicity and robustness of the OpenBOM data model allow providing a powerful solution to a growing number of small and medium-sized companies.

Conclusion

At OpenBOM, products are represented by complex multi-disciplinary structures. These data structures allow for the management of complex product structures and have the ability to dynamically present views of the structure to support a variety of product representations – engineering, manufacturing, sales, support. Such an approach creates a flexible and scalable data management architecture to support a variety of customer needs and model multi-view BOM management architecture.

Check how OpenBOM can help you today – REGISTER FOR FREE and start your 14-day trial to explore all of our features.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.