The success of any business depends on its ability to innovate and bring new products to market efficiently. For manufacturers, it means to go quickly from initial idea to realization delivering what customers want, fast with the optimal cost. Faster, better, cheaper. I bet you’ve heard that many times. But what does it mean for the real manufacturing business such as for example a small hardware startup building a consumer product or medical device manufacturer working on new equipment or a large CPG company exploring the development of new home cleaning robots?

OpenBOM is a cloud-based product data development platform that streamlines NPD and connects various processes involved in bringing a new product from concept to market. In this blog post, we will explore how OpenBOM facilitates agile new product development (NPD) processes and enhances connected processes within organizations.

Why NPD at all?

The common thing between all these companies is the need to establish a new product development process. This new product development (NPD) is a complex and multifaceted process that involves various teams and stakeholders working together seamlessly.

What we found from the very early beginning of working with customers using OpenBOM is that this NPD process is different from a traditional way of thinking about PDM, PLM, ERP, and other systems used in engineering and manufacturing.

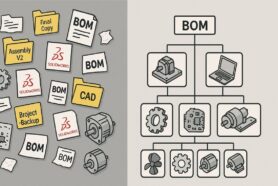

The picture below shows you a traditional environment, which has a siloed organization of work. These people are not communicating or communicating poorly. They don’t use special data management tools and use emails and file sharing services to exchange information.

Illustration idea credit PLM advisors article – What is PLM?

Bringing them “traditional” PDM/PLM/ERP tools to the game sounds like a possible solution. But here is the thing that we learned at OpenBOM and the main three reasons why traditional solutions don’t provide an efficient mechanism to solve the problem.

- Each application (eg. CAD, PDM, PLM or ERP) is optimizing a single silo in the chain of operations and activities you see in the picture above. For SMB/SMEs, these tools are very often overkill and companies don’t have them. Even in the case a company has these tools, the connectivity between them is sub-optimal and the process is too complex.

- The goal of each of these tools is to establish a department-level process. None of these processes are designed to work together and support a single goal of New Product Development with information transparent between multiple tools and groups of people.

- For large enterprises, these tools are set up and configured for enterprise processes that are slow and don’t fit the goal of quick and efficient collaboration and data sharing.

We found these three reasons very typical and happening very often in the large number of engineering and manufacturing teams working on new products. We’ve seen it happening for small companies and startups as well as for large enterprises.

The Importance of Efficient New Product Development

New Product Development (NPD) is the lifeblood of many businesses. It is the process of conceptualizing, designing, and bringing a new product to market. NPD involves multiple stages, including idea generation, market research, product design, prototyping, testing, manufacturing, and marketing. The successful execution of NPD can lead to increased market share, revenue growth, and improved competitiveness.

Efficiency in NPD is crucial for several reasons:

Speed to Market: The faster a company can bring a new product to market, the more likely it is to capture market share before competitors.

Cost Control: Efficient NPD helps control development costs and ensures that resources are used effectively.

Quality Assurance: Well-managed NPD processes help maintain product quality and reduce the risk of defects or recalls.

Collaboration: Effective collaboration among cross-functional teams is essential for successful NPD.

How OpenBOM Enhances NPD

At OpenBOM, we came up with the new idea of how to support agile new product development. Agile is the name of the game in many industries. OpenBOM is designed to enhance the NPD process by providing a central platform for managing product data and BOMs including design files, capturing information, managing vendors, catalogs, suppliers, order planning, and purchases. An end-to-end process gives you a way to connect all players together to streamline the process.

The key innovation of OpenBOM is real-time collaboration and connectivity of four major activities: (1) Design, (2) BOM, (3) Purchase; and (4) Assembly. The process OpenBOM invented can boost the productivity of engineering and manufacturing teams enormously.

But collaboration and data communication is not all. You can do real-time collaboration using Google Spreadsheets, but it doesn’t solve the problems OpenBOM does. Here is what you can do with OpenBOM.

Connected NDP Processes with OpenBOM

Here are some ways in which OpenBOM features enable NPD:

Centralized Data Repository: OpenBOM serves as a single source of truth for product data, making it accessible to all stakeholders. This eliminates the need for multiple spreadsheets and documents scattered across different teams and departments.

Real-time Collaboration: OpenBOM facilitates real-time collaboration among team members, both within and outside the organization. This is especially valuable for geographically dispersed teams and external partners.

Version Control: OpenBOM keeps track of changes made to product data and BOMs, ensuring that everyone is working with the most up-to-date information. This minimizes errors and confusion.

Bill of Materials Management: OpenBOM allows for the easy creation and management of BOMs, including multi-level BOMs. This is crucial for understanding the components and costs associated with a product.

Integration with CAD Tools: OpenBOM integrates seamlessly with popular CAD tools like SolidWorks, Autodesk Fusion 360, and Onshape, allowing engineers to link CAD models directly to BOMs.

Inventory and Vendor Management : OpenBOM provides a way to manage quantity on hands for each component, vendors and sourcing information. Combined with small batch planing process, it allows to customers to have all information about stock, prices, contractors and supplier handy. And to send PO when having full info about components.

Here is a high-level overview of the process.

The set of functions supported by OpenBOM is typically found in three systems – PDM, PLM, and MRP/ERP. But the difference is that OpenBOM provides connected, flexible, and optimized that can be used for a team looking at how to collaborate and work together.

Conclusion

OpenBOM is a powerful tool that enhances the new product development process and fosters connected processes within organizations. By centralizing product data, enabling real-time collaboration, and supporting various stages of NPD, OpenBOM empowers businesses to bring innovative products to market efficiently and with greater success.

In an increasingly competitive marketplace, adopting modern tools like OpenBOM can be a game-changer for businesses looking to stay ahead of the curve in new product development.

REGISTER FOR FREE and test full functionality for 14 days to learn more about how OpenBOM can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.