OpenBOM is an online platform that helps engineering teams and industrial companies to manage product information and product development processes. OpenBOM helps organize siloed information and connect engineers, manufacturers, and supply chains. This article will help you get an initial understanding of what OpenBOM is, how it works, and what it does.

The vision of OpenBOM is to organize and connect information, streamline communication and eliminate the need to use various unstructured data sources such as different spreadsheets and documents.

1. Introduction to OpenBOM

OpenBOM is a digital network platform designed to manage product data and facilitate the sharing of information among manufacturers, contractors, and suppliers. It delivers cloud-based, real-time collaboration, enabling teams to create and manage product structures (bill of materials – BOMs), inventories, and other related data.

OpenBOM aims to bridge the gap between various design tools and manufacturing systems, thus simplifying the production process. With its functionalities, it empowers companies to streamline their data management, reduce errors, and improve efficiency across the entire product lifecycle.

OpenBOM is an online platform, so you need an account and password to get it. Think about global online platforms like Google, Microsoft Office 365, Autodesk, PTC Onshape, and some others, you can use it as a user and access the information via browser or via tools integrated with other applications.

Every user has a login, which is associated with the company account. Company admin can set up an access level allowing you to get access to a specific set of information. The access level can be very generic (like “everything read or edit”) or very granular limiting access to a specific set of attributes (eg. cost, or engineering files) or specific objects (eg. BOM or catalog).

If you use OpenBOM in the browser, the first thing you see after the login is a browser with multiple dashboards allowing you to see different sets of information – design, parts and BOMs, production planning, change management, and custom object (note: new, coming soon).

2. OpenBOM Data Management

OpenBOM provides a flexible and configurable data model allowing customers to manage the data about the products they need and also to support processes in their organizations such as design, engineering, production, procurement, and supply chain.

The foundation of OpenbOM data management is a graph-based multi-tenant data model allowing the creation of objects and relationships. Flexible object definition and structure allow for the management of various characteristics (properties) and connect them together.

By providing a flexible configurable data model, OpenBOM helps to connect different product lifecycle stages and different companies to operate together in a connected way.

Multi-tenant capabilities of the OpenBOM data model allow multiple users, teams, and companies to isolate the data in their accounts but also share it in real-time. So, if you need to share data with contractors or suppliers, you don’t need to export the data to an external file, but you can share it (think Google-docs like style) and edit it simultaneously at the same time. [Note: check more about real-time collaboration]

The core data elements of OpenBOM are configurable object types and product data models allowing us to define items (eg. Parts or Assemblies) or other types of data and different types of product structures (xBOM).

3. Main OpenBOM Object Types

OpenBOM provides out-of-the-box data objects and also allows the creation of custom object types (June 2023 note: the function of the custom object will be available for end users in the coming months).

These are the primary predefined object types in OpenBOM you will see in your account after registration to OpenBOM.

- Folders and Files (Design): These are objects to represent the design data (eg. CAD files or design objects stored in cloud CAD systems). OpenBOM allows the managing of design data using multiple services such as storing files on a virtual disk (Drive) or connecting directly to a cloud CAD service. OpenBOM settings and CAD integrations allow you to connect to different design data structures to manage them or to extract data from online CAD services.

- Items (Catalogs): This is an object that represents the foundation of the product data model. Every element of the product can be defined as an item (eg. a screw, resistor, chip, assembly, or an entire product). By defining multiple catalogs, OpenBOM allows you to create a classification of items, each type (catalog) has a specific set of attributes.

- Product Structure (xBOM): A BOM is a data structure that represents relationships between items and allows to store and manage product structures, which is from a technical perspective represented as DAG (direct acyclic graph), which is known to everyone as a multi-level Bill of Materials.

- Planning or Order (BOM): This is a model that allows performing production planning and includes a separate BOM (planning or MBOM) currently used to scale an individual product BOM to a number of production units, to calculate purchasing gaps based on the inventory levels and select vendors to create RFQs and Purchase Orders (POs)

- Vendors: This is a set of objects to manage contractors and suppliers. It includes all information about suppliers and can be used for “sourcing” functions in catalogs to define multiple suppliers to purchase services or components from.

- Custom Object [Note: coming soon] While out-of-the-box object models provide a rich set of modeling capabilities, OpenBOM is bringing a way for users to create their own custom objects to manage any type of data. You think of products, projects, tasks, requirements, etc. Custom objects use the same ability to add custom properties to each object, and to create custom links between objects.

4. User Experience, Collaboration, and Navigation

OpenBOM provides a flexible and configurable user interface inspired by the simplicity of the spreadsheet editing model. It allows flexible and configurable definitions of visual elements in different ways – flat grid, multi-level grid, and visual tree/graph navigation. Here are examples of Bill of Materials presented in a multi-level grid with custom attributes.

To visualize the connectivity between data elements, OpenBOM provides visual graph navigation capabilities such as a hierarchical tree or property graph navigation.

More flexible object-link navigation capabilities allows you to drill-down into relationships between objects and navigate between complex elements of the information (design, engineering, purchasing, etc.)

To support configuration and customization, OpenBOM provides a configurable user-defined view to present data in a variety of forms (eg. Engineering, Manufacturing, Contractor, etc.)

To support collaboration and efficient communication, OpenBOM allows simultaneous editing capabilities by allowing multiple users to edit the same view of data shared and edited at the same time.

5. Lifecycle and Change Management

OpenBOM allows tracking the history of changes and managing revisions and change processes. Similar to GitHub and modern cloud CAD systems, OpenBOM allows the management of a baseline (latest state) of changes and also captures immutable snapshots (to manage revisions). Integrated change management system support requests for approvals and notifications.

6. Integrations

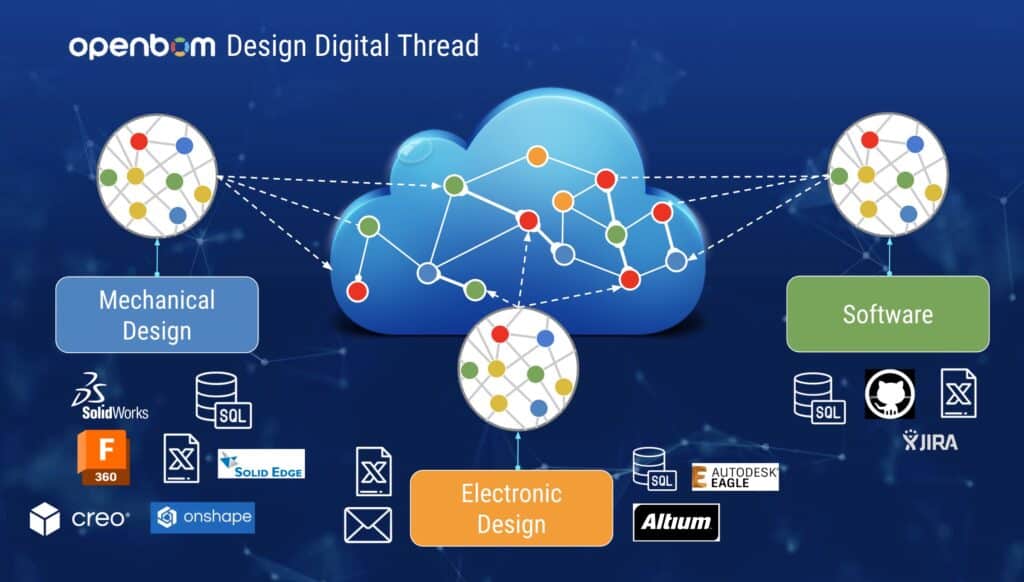

The power of OpenBOM beyond data management itself lies in its ability to integrate with a host of other tools and platforms, further enhancing its functionality and scope. With seamless integration into various CAD, PLM, ERP systems, and even Excel, data transfer becomes hassle-free, eliminating the risk of manual errors and improving productivity.

OpenBOM supports integrations with popular CAD tools such as Solidworks, PTC Onshape, Autodesk Inventor, and Autodesk Fusion 360, to name a few In addition to CAD integrations.

OpenBOM integrates with a wide range of engineering and enterprise systems providing out-of-the-box and custom integrations. These integrations enable automatic extraction and updating of BOM data directly from the source systems or files.

By integrating with different design systems, OpenBOM allows the organization and manage a connected digital design data thread.

Also, it can integrate with ERP systems like SAP, Oracle, or Microsoft Dynamics to streamline the transfer of BOM data into production workflows.

Through its REST API, OpenBOM also provides the capability to build custom integrations, further enhancing its interoperability.

Conclusion:

OpenBOM is a powerful and flexible platform that offers real-time collaboration and data management for manufacturing and design processes.

Its dynamic data model, custom objects, multi-tenancy features, and robust integrations make it an indispensable tool in today’s complex and fast-paced production environments. By centralizing data and streamlining processes, it empowers companies to improve efficiency, reduce errors, and enhance their decision-making process.

REGISTER FOR FREE and try all OpenBOM features for 14 days with no commitment.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.