OpenBOM’s vision is to assist manufacturing companies in utilizing data more efficiently and supporting their decision-making processes. We recognize that this is not an overnight task. In my previous articles, I have discussed the necessity for digital transformation, the more accurate use of data, and the shift from data control to intelligence in Product Lifecycle Management (PLM). You can check out my articles about knowledge graph and future development of PLM technologies.

- The importance of knowledge graph for future PLM platforms

- PLM Trajectory from CAD files, to product data, knowledge graphs, AI and GPT models

- Data-Driven Platforms for PLM

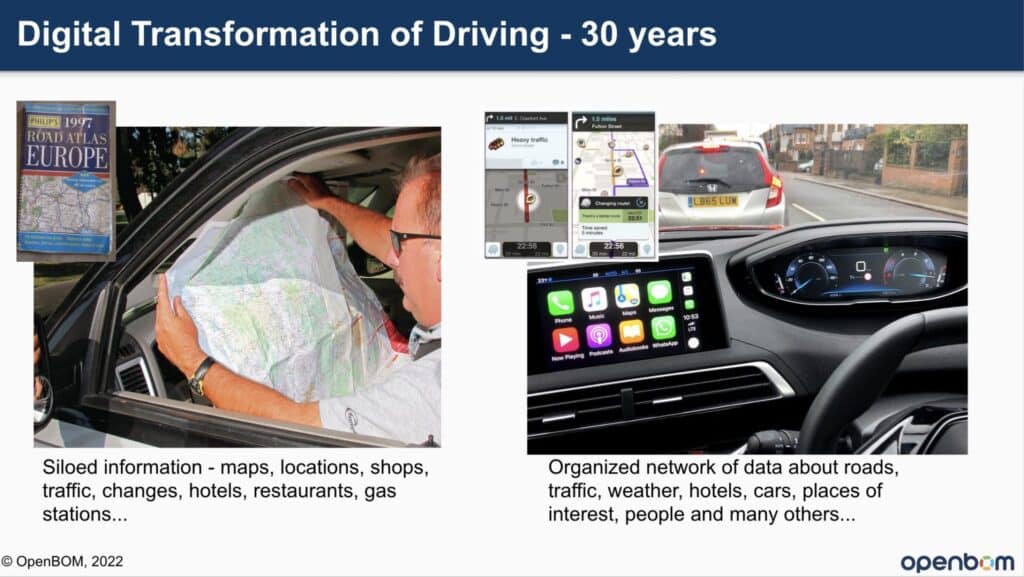

Achieving a product knowledge graph vision cannot happen overnight. Consider the digital transformation of the driving process—it didn’t happen overnight either. It took years to transition from paper maps to digital driving assistance and the autonomous driving reality we see today.

In manufacturing, we have seen growth in the use of digital technologies, cloud infrastructure, and a shift from documents to data and analytics over the last decade. While we have not fully arrived yet, the opportunity within the industry is immense, with momentum building around modern graph databases, data integration, key-value stores, document databases, multiple data storage technology, cloud infrastructure, recent developments in SaaS tools, and interoperability.

It’s evident that the manufacturing sector’s shift towards digital technologies, multiple data stores, improved data governance, cloud infrastructure, and data analytics has been steadily growing. Yet, the journey towards fully harnessing the power of these technologies is still ongoing. The potential within the industry is immense, supported by modern databases, cloud infrastructure, recent advancements in SaaS tools, and interoperability.

Product Knowledge Graph Pyramid

Today, I’d like to share the vision OpenBOM has for constructing a product knowledge graph. It includes and relies on different data storage technologies and contains five stages, similar to Maslow’s hierarchy of needs: platform, product data, analytics, knowledge, and intelligence. Each stage represents a fundamental layer in building a comprehensive system that not only manages data but also generates actionable insights and intelligence.

Here are some details of the roadmap and implementation status.

Let me talk about some details of this roadmap.

Platform

The foundation of OpenBOM’s vision lies in establishing a robust platform that incorporates cloud architecture, storage, multiple data storage technologies, graph databases, and data models. By developing a multi-tenant system that employs a polyglot persistence data architecture, OpenBOM leverages GraphDB alongside other modern data management tools. This foundation supports a multi-tenant data model, ensuring scalability and flexibility across different manufacturing domains. It allows OpenBOM to create a robust data management foundation supporting multiple customers in the same platform working globally and sharing data in real time.

Product Data

At the core of any manufacturing process is the product data. OpenBOM focuses on creating a flexible data model that caters to specific PLM domain requirements and customer schemas. Integration with engineering tools and other relevant systems is pivotal, facilitating seamless data flow and accessibility across different stages of product development. The recent introduction of custom data objects takes the capability of OpenBOM to create any data types in addition to core instance reference product data model for items/product structure.

Analytics

The third stage dives into analytics, where OpenBOM is actively developing efficient graph data query capabilities powered by GraphDB and Graph Data Science.

This step is crucial for transforming raw data into meaningful insights, enabling stakeholders to make informed decisions based on real-time data analysis. It includes both visual navigation and graph queries.

Our long vision is to create Graph Centered Applications using data managed by the OpenBOM platform.

This is the stage we are at right now. We collected a lot of experience in capturing digital information from design and engineering systems, Excels and different databases by helping engineering teams and manufacturing companies to manage data. The data is a foundation of the next steps. Our goal is to be able to transform this data into knowledge and intelligence. But the first step is to run intelligent queries enabled OpenBOM graph data model and graph data science algorithms. Also to allow to these queries to run super fast (unlike traditional SQL queries). To give you an idea of these queries – what is mostly used parts across multiple product lines (or BOMs), what is most critical supplier, and many others.

Knowledge

The vision extends into the space of ontologies and provenance, aiming to construct specific engineering and manufacturing ontologies. Leveraging Large Language Models (LLMs) to support the product development process signifies a leap toward understanding and utilizing the vast amounts of data generated in manufacturing, laying the groundwork for knowledge-based decision-making.

Intelligence

The final step of OpenBOM’s vision is to deliver intelligence tools that act as BOM AI copilots, offering various intelligence and decision support tools. These advancements promise to revolutionize how decisions are made within the manufacturing sector, making processes more efficient, predictive, and adaptive to changing market dynamics.

Conclusion

Reflecting on the evolution of PLM platforms, which were predominantly developed over 25 years ago using relational databases, it’s clear that there exists a substantial technological gap in managing product data efficiently. OpenBOM leverages the burgeoning maturity of graph technologies and AI tools to construct a new breed of PLM software platform. This approach not only addresses the current inefficiencies but also paves the way for a future where data-driven decision-making is at the heart of manufacturing processes.

Interested to learn what OpenBOM does, contact us directly.

REGISTER FOR FREE and explore how OpenBOM can help.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.