One of the frequently asked questions by customers is, how can OpenBOM help manage revisions and lifecycle of objects?

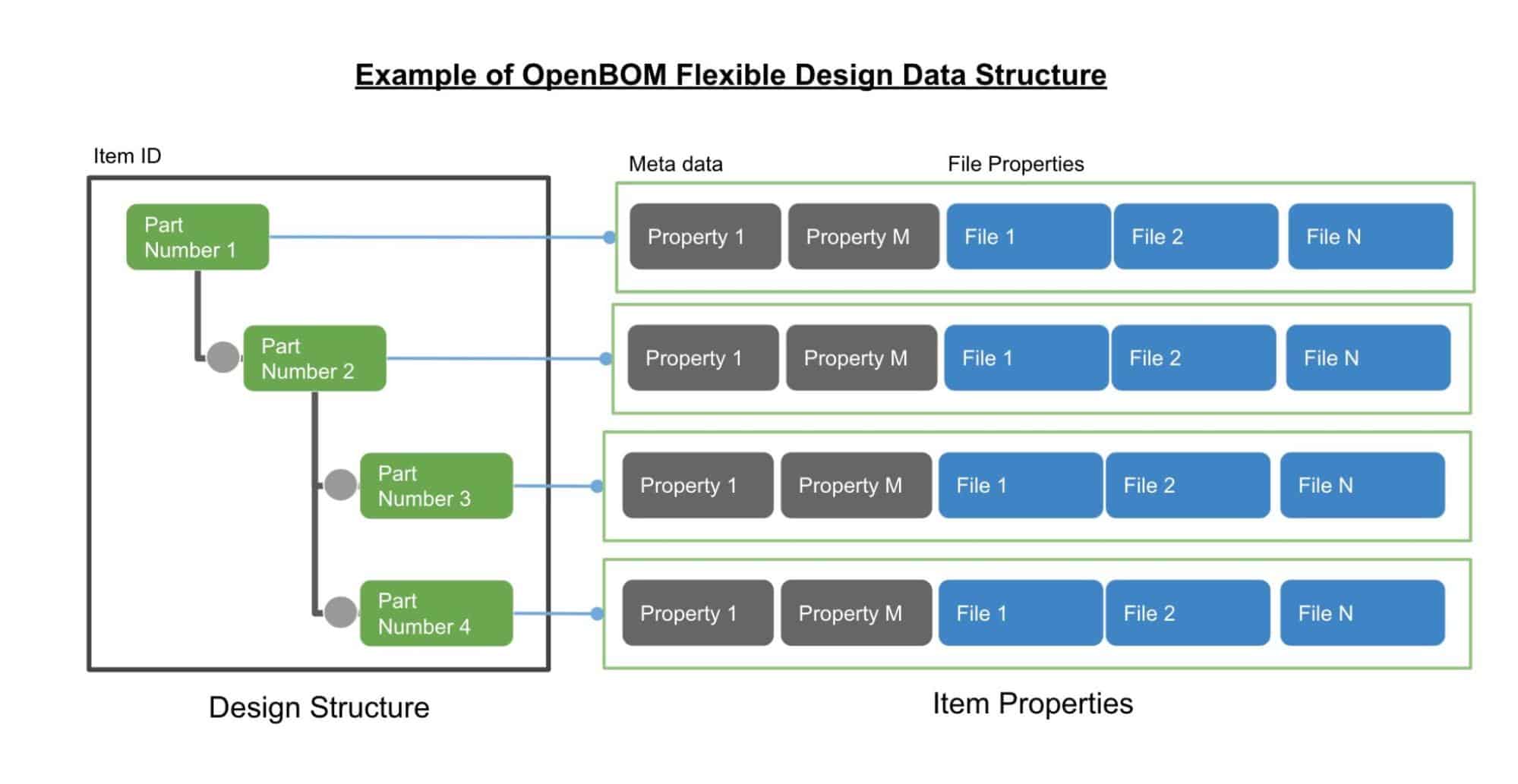

In my blog post today I’m going to provide a synergy of materials explaining how OpenBOM’s flexible data model can be used to create a record of files and more specifically CAD files. I’ll also be discussing how the data in CAD files are managed as part of a bigger multi-disciplinary data set and how OpenBOM helps to track revisions of the data and files as well.

Flexible Data Model – File Properties, Items, and Structure

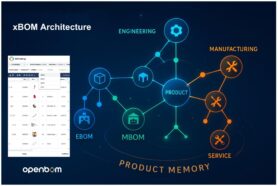

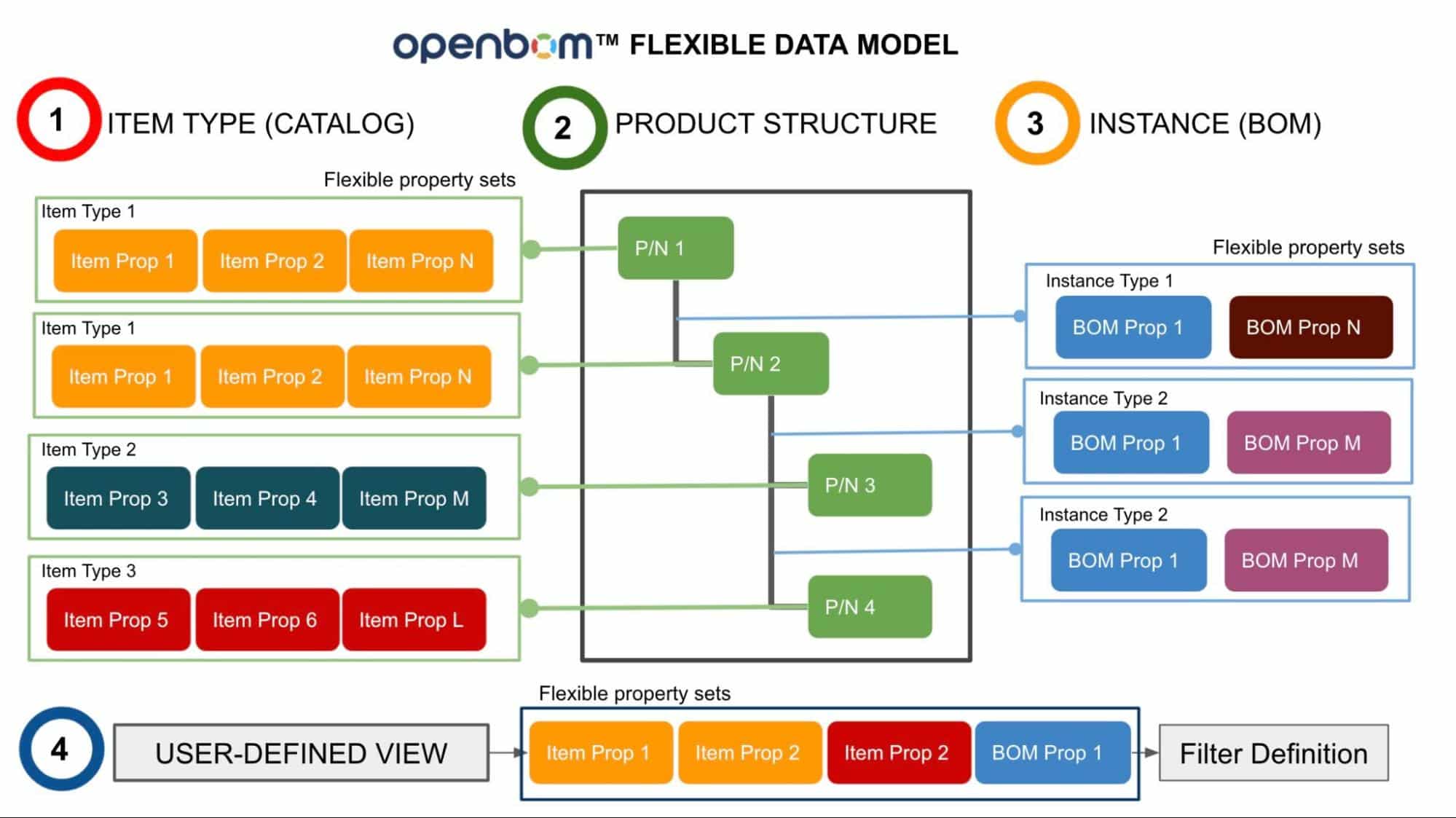

The foundation of OpenBOM is a flexible data model. Check out OpenBOM’s online documentation which gives you a detailed description of the data model, what is an item (reference), catalogs, product structures, and how files can be stored in item (reference) or BOM (instance) properties.

In a nutshell, OpenBOM is using the following data objects – item, BOM to manage the data records. A flexible number of properties can be added to the item to manage multiple files attached. Although you can also add files to item instance records (BOMs), I will omit this description for simplicity.Multi-Disciplinary Data Structure

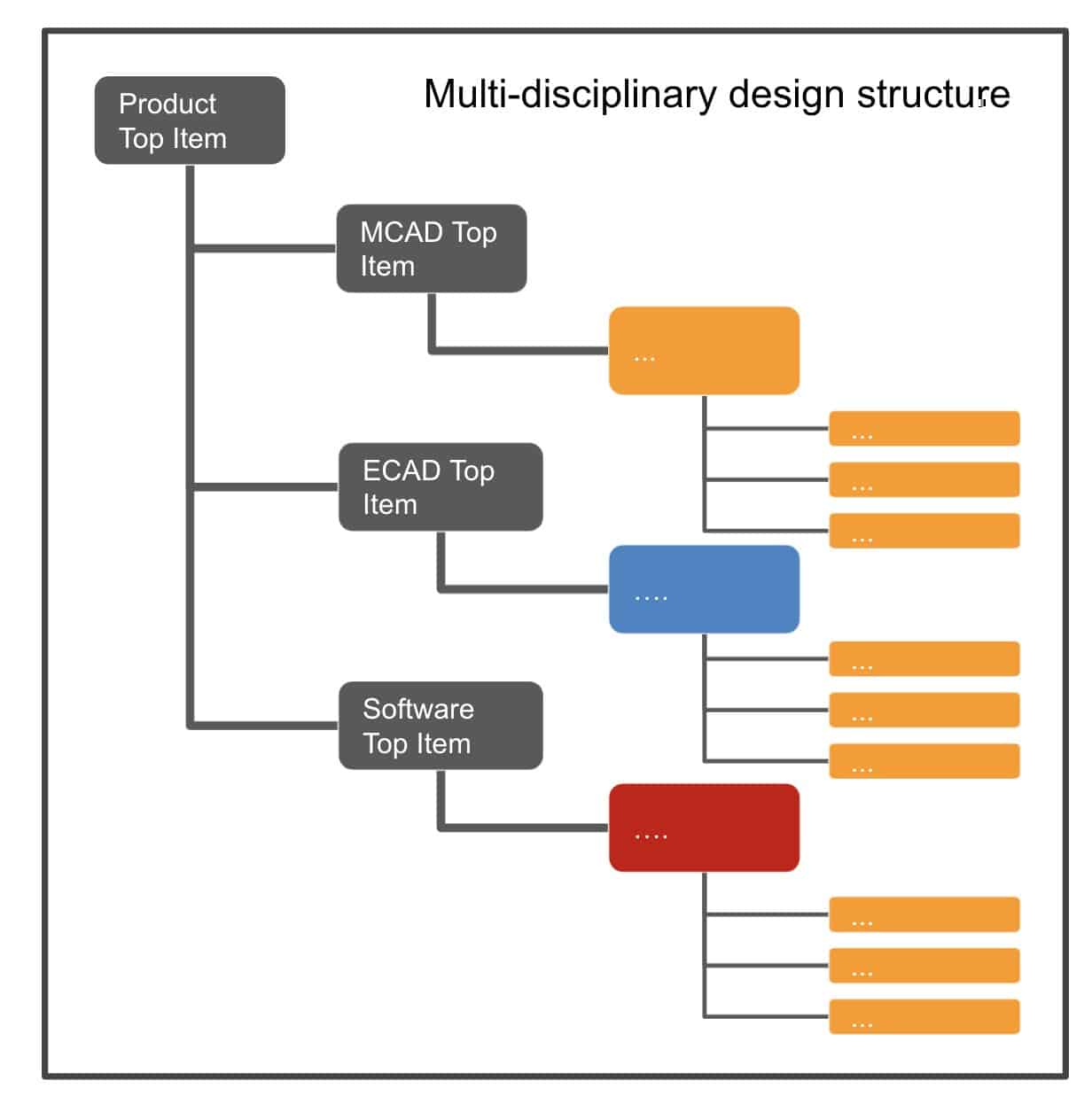

The flexibility of OpenBOM’s data model allows you to easily organize a multi-disciplinary data structure by creating hierarchical relationships between items of different types. In the picture below, I illustrate how a schematic structure contains top Product Items and 3 sub-items each for MCAD structure, ECAD structure, and Software BOM.Item Revisions and Product Structure

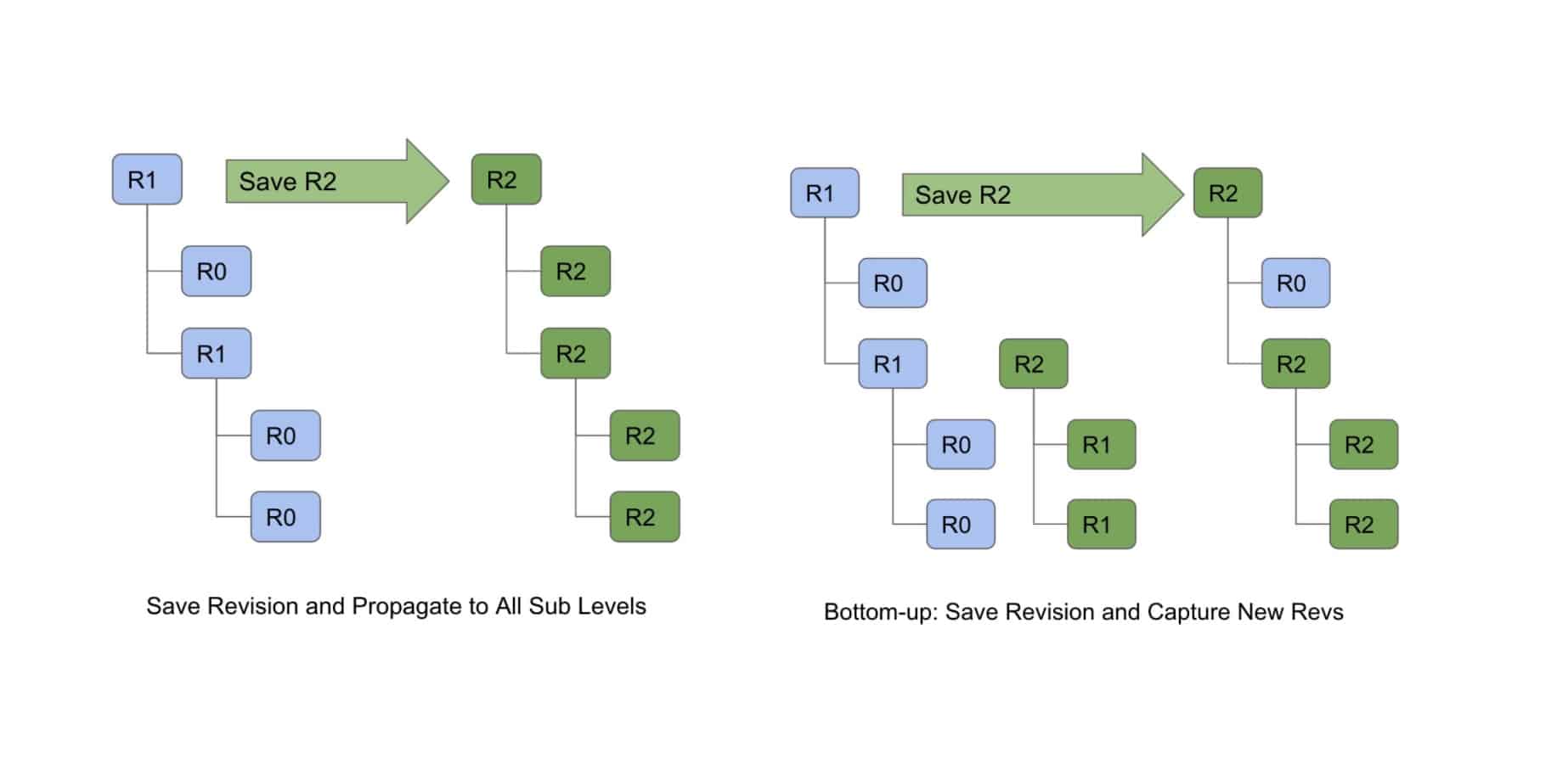

Another dimension of the data model is management of revisions. When you create a data structure, it is created in the so-called “Latest” or “Work-in-progress” model. This is a status in which the data can be changed (based on your access level, of course). Once you finish editing a specific item data, you can create revisions (immutable records of the item data for each revision. These revision records are preserved and OpenBOM allows you to create an unlimited track of historical records. OpenBOM manages immutable records for both items and BOM (relationships). OpenBOM data graph keeps track of relationships between different revisions, so you can also get the right structure for each item revision.Conclusion

OpenBOM flexible data model provides a robust way to manage a specific CAD structure (eg. MCAD, PCB, etc.) and also a bigger scope of the data such as higher-level structures of components assemblies, systems including electronic design, software components, and others. A universal identification system (based on a Part Number) allows you to identify any type of item and connect multiple files to each record. Item revision mechanism allows you to keep track of changes, preserve the history of each item as well as relationships between Item revisions.

Want to learn more about OpenBOM’s data model and revision control? Then, REGISTER FOR FREE and start your 14-day trial and explore OpenBOM today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.