User experience and simplicity mean a lot. The ability to seamlessly navigate your product data is no longer a luxury—it’s a necessity. As companies design increasingly complex products, managing the relationships between Items, Assemblies, and Products becomes central to maintaining accuracy, reducing errors, and responding quickly to changes.

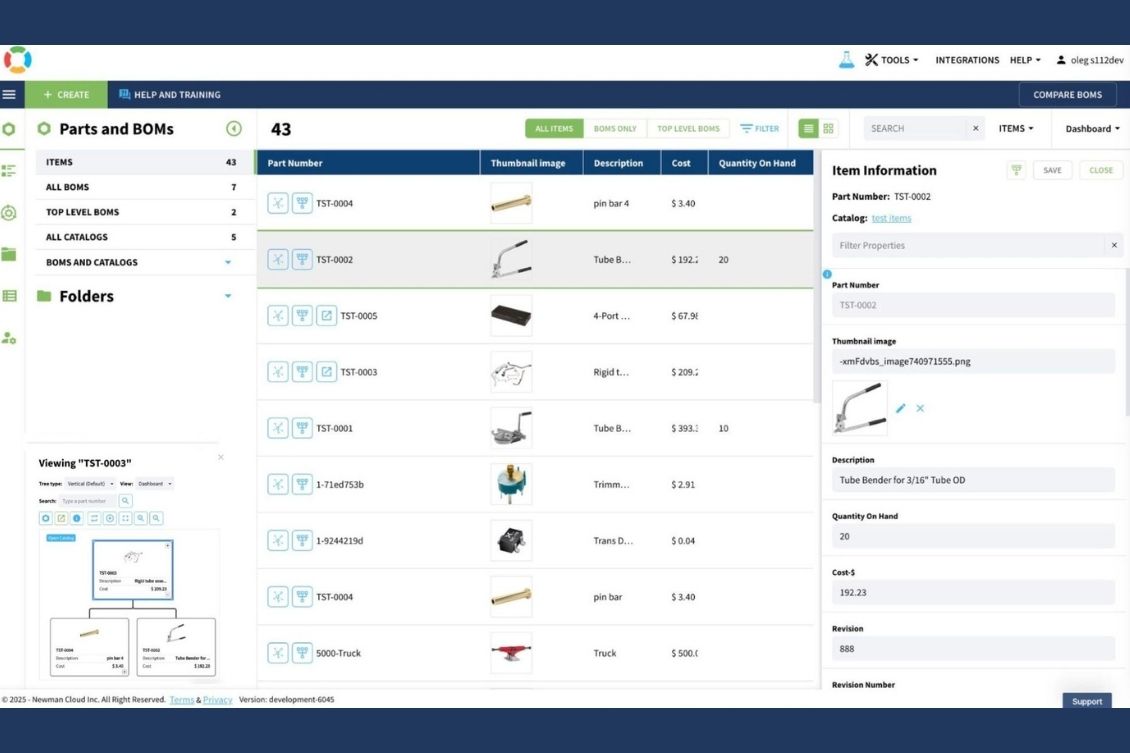

That’s why we’re excited to unveil an improved navigation mechanism for items, assemblies, and products in the coming OpenBOM ITEMs dashboard that refines how you interact with your product data. It is more “data oriented” and less reminiscent of your old “Excel-file” like approach.

Whether you’re reviewing a part, exploring a multi-level assembly, or assessing the impact of a change across your entire product line, OpenBOM now makes it easier than ever.

The Challenge of Navigating Product Data

Let’s face it—product data is inherently complex. Each part isn’t just a line item in a BOM; it might appear in dozens of assemblies, exist across multiple product variants, or be sourced from different suppliers. A simple resistor might live in ten different subassemblies across five product families, each with different cost implications, revision histories, and sourcing constraints.

Understanding this interconnected world requires more than just access to data—it demands a way to move through that data intuitively.

Moving Through Items, Assemblies, and Products

With the updated navigation experience in OpenBOM, moving between Items, Assemblies, and full Products feels much more natural.

OpenBOM ITEMs dashboard brings a search driven dashboard with automatic and dynamic filters for items, assemblies, and products. Combined with a completely flexible data model and visualization capabilities, it gives an easy way to move from items, to assemblies, products, where to use, navigate to different BOMs (EBOM, MBOM, PBOM), check dependencies (Where used) and use graph navigation capabilities.

Understanding Impact: Where-Used, Done Right

One of the most powerful tools in any product data management system is the ability to perform impact analysis—to understand where a part is used, how a change might ripple through your product lines, and what needs attention before something breaks.

The new navigation capabilities in OpenBOM enhance this critical functionality. When you’re looking at an item, you can now instantly run a where-used query to see all the assemblies and products that reference it. This isn’t just a flat list—OpenBOM contextualizes each usage, showing you how and where the part is consumed.

Imagine discovering a quality issue in a common motor component. You can now identify every single assembly and product affected, navigate directly to those BOMs, and initiate updates or replacements—all without breaking your workflow. It turns what used to be a multi-hour research task into something you can accomplish in minutes.

Why Navigation Is More Than a Feature—It’s a Foundation

At its core, this improved navigation isn’t just about convenience. It’s about empowering your engineering and manufacturing teams to understand the product data they rely on. Better navigation reduces friction, eliminates wasted time, and enables decisions to be made with confidence.

More importantly, it reflects the way real product development happens. Engineers don’t think in linear spreadsheets. They think in relationships—how one component influences another, how designs evolve, how changes cascade. OpenBOM’s updated navigation aligns with that mental model, letting users work the way they think.

Video: See it today

Check the video with the new navigation experience. It is now available to all OpenBOM users. Whether you’re a long-time user or just getting started, we think you’ll feel the difference right away.

Conclusion: A Step Toward a Smarter, More Connected Future

This release is part of a broader mission at OpenBOM to create a system where data flows freely, collaboration happens naturally, and digital threads connect every part of the product lifecycle. Navigation is foundational to that vision.

When it’s easy to move between data, it’s easier to trust that data. When it’s clear where a part is used, it’s easier to manage change. When you can see a product as a whole and still dive into the details, you can design better, build faster, and deliver with confidence.

REGISTER for OpenBOM and explore your Items, Assemblies, and Products like never before. And don’t forget to test out the new where-used functionality—it might just become your favorite feature.

Let us know what you think.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.