Welcome to the best practices blog series. From time to time, we publish quick tips about OpenBOM functions that can boost your performance and save you tons of time. Today, we’re diving into the world of engineering performance and exploring why quick editing of Bills of Materials (BOMs) is a critical factor for success.

BOMs are the backbone of any engineering project, serving as the foundation that defines all the components, materials, and sub-assemblies required to build a product. Efficiently managing BOMs is essential to streamline the engineering process, ensure accurate communication among team members, and meet project deadlines.

Today we’ll delve into the reasons why quick editing of BOMs is crucial for engineering performance, including reducing errors, improving collaboration, accelerating design changes, and enhancing overall productivity.

The reason why many engineers like Excel is because they feel it is the quickest way to edit bills of materials. With OpenBOM we wanted to prove that you can be as fast as Excel, but provide tons of intelligent functions knowing how to edit Bill of Materials and product structures.

OpenBOM Core – Reference-Instance Product Model

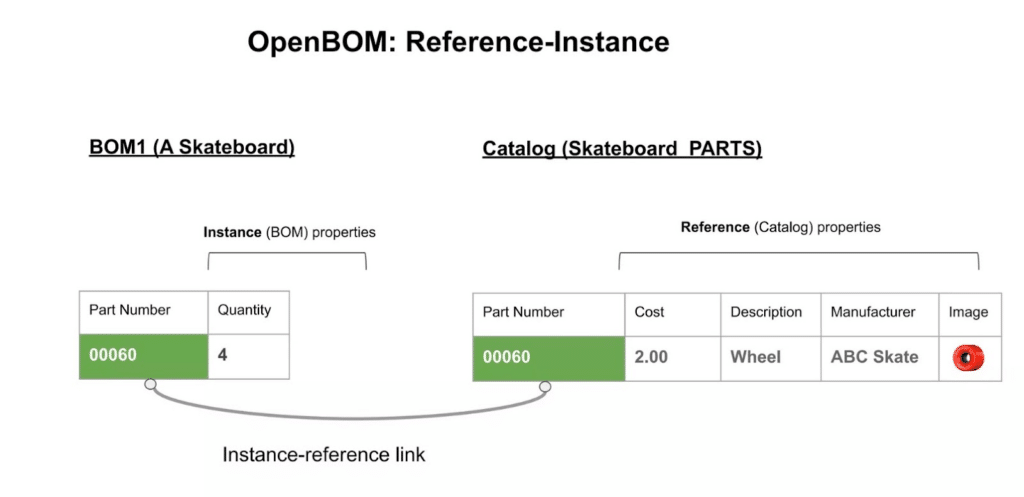

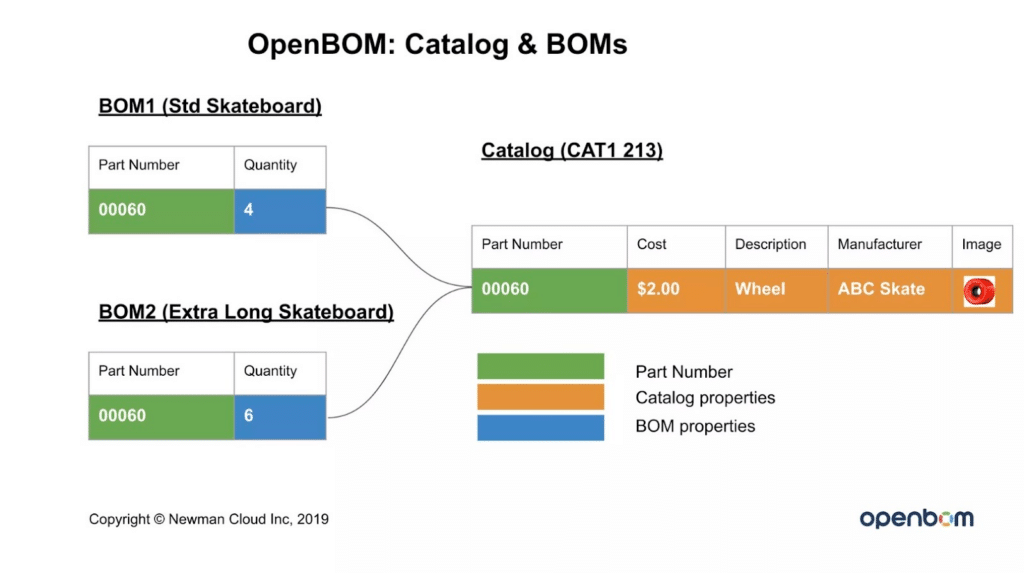

OpenBOM Reference-Instance model allows you to manage items (reference) and instances (part) connected to create product structures. You do it by creating a set of catalogs to manage a database of all items used in products and instantiate these items in a variety of Bills of Materials. This simple yet powerful paradigm allows full customization freedom on both reference and instance levels for the most flexible data modeling.

In the following pictures, you can see the OpenBOM reference-instance model explained. Instance reference links connect records of items (in the catalog) with the multiple records of instances in the BOM(s). By doing so, the OpenBOM data model allows you to manage complex product structures with full flexibility of customizable attributes in both item and instance records.

As you can imagine, a single-item record can be referenced in multiple BOMs. By doing so, OpenBOM keeps track of a single source of truth for all Item records in all BOMs.

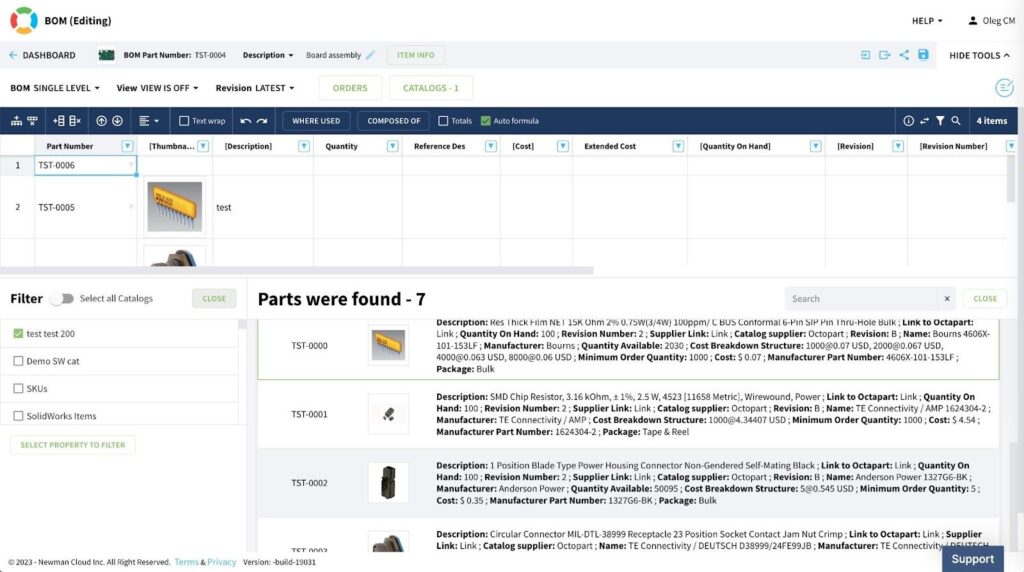

Now, let’s talk about how we can make it work from a user perspective. OpenBOM gives you a user-friendly interface that allows you to select items from multiple catalogs using the search function and insert them in the BOM when you create a new BOM.

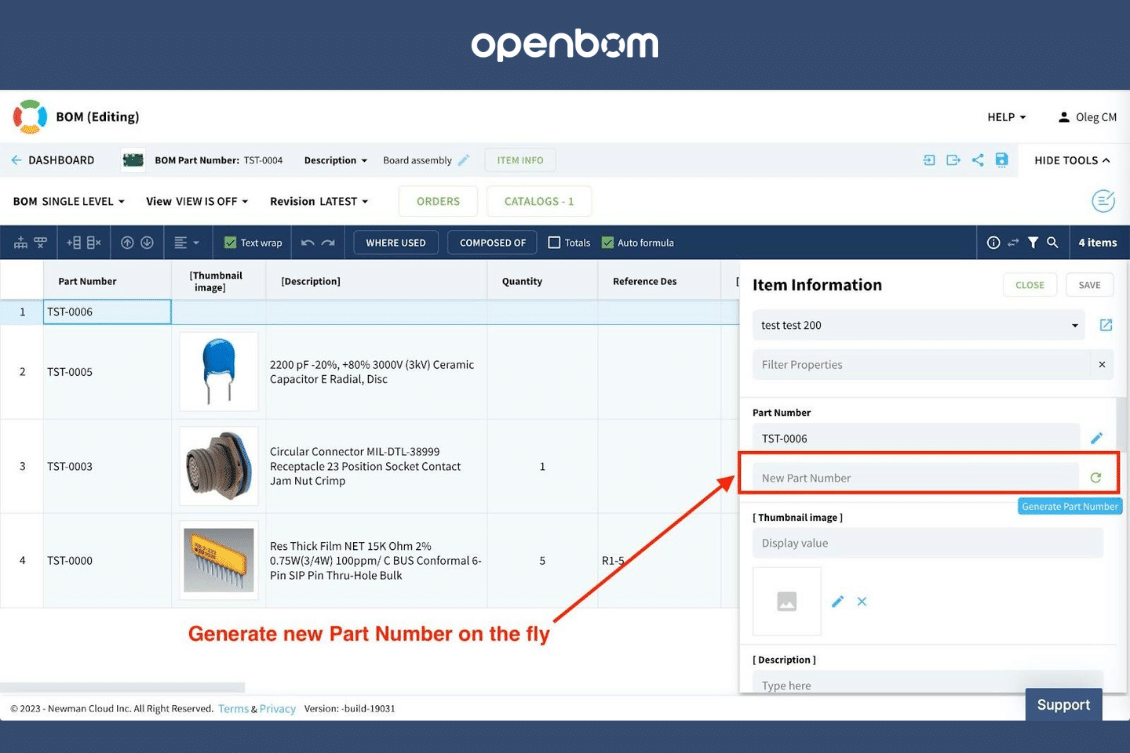

But what if you need to make a new item? How can you easily generate a new Item with a new Part Number and make your user experience nice and simple? Let’s talk about it.

New Part Number BOM Function

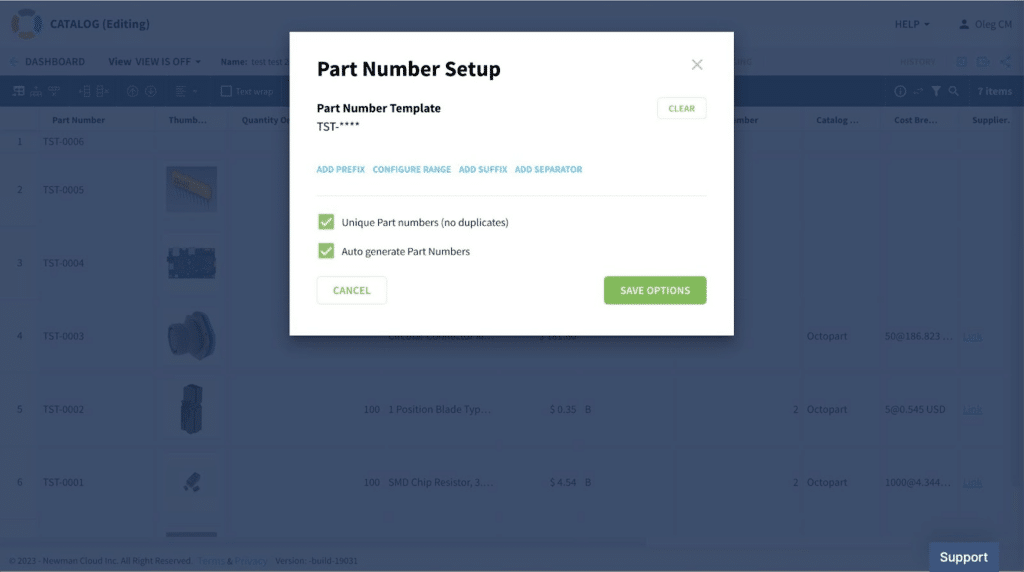

The foundation of the Part Number generation mechanism is Part Number Setup, which is available in each catalog and it allows you to define prefixes/suffixes/ranges. You can also create a custom Part Number generation function using REST API.

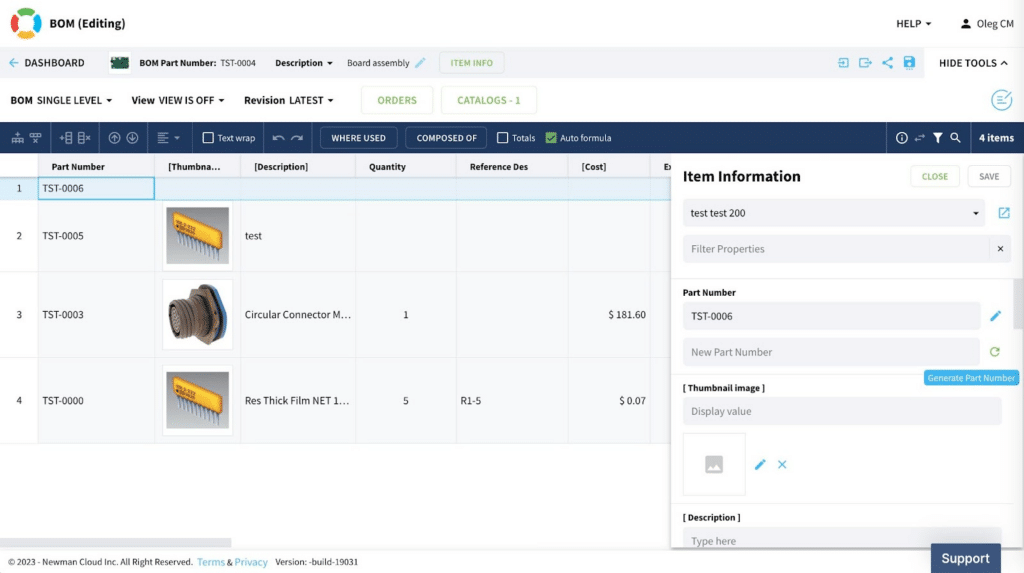

Once, the part number setup is done, you can add a new Item to a BOM and use the Info item panel to get access to a new part number generation function.

That’s it! Simple and Easy. All you need to do is navigate to the Item Info panel and get a part number for the new item.

Video Preview

Please watch this video to learn how to generate a new part number with just a few clicks without leaving the BOM screen.

Conclusion:

OpenBOM’s success depends on user experience (UX) and simplicity. An easy-to-use platform with an intuitive interface saves time and costs, enhances collaboration, promotes scalability and adaptability, and boosts user satisfaction and retention.

With a user-friendly design, OpenBOM streamlines the product development process, fosters efficient collaboration, and ensures customer satisfaction, making it a powerful tool for managing bill of materials (BOM) data.

At OpenBOM we invest a lot into how to simplify complex functions and make it easy for engineers working with the system. One of the reasons everyone loves Excel is that it is simple and easy to operate. But Excel brings mess into your data within time. Therefore, at OpenBOM we decided to combine the best of both words – the simplicity of spreadsheet and sophisticated data management to manage product structure, easily edit bills of materials, and keep information consistent.

New Part Number generation that can be easily done using embedded functions into simple BOM editing capability is just one example.

REGISTER FOR FREE to check OpenBOM out with a 14 day trial.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.