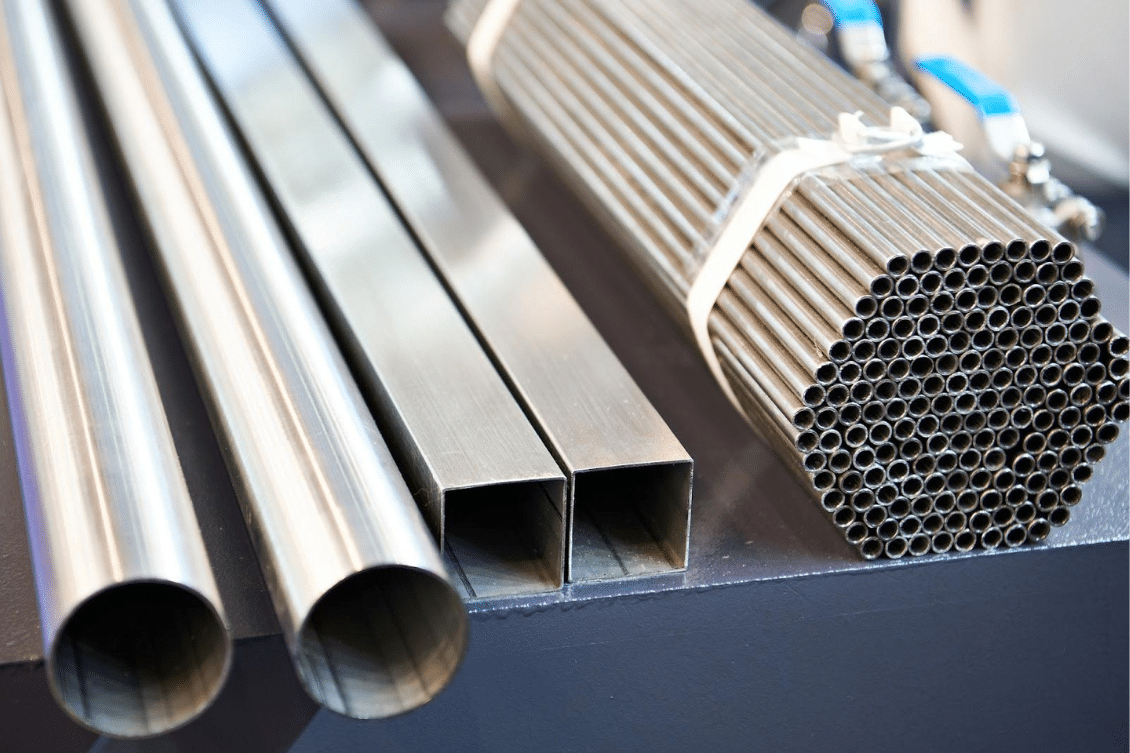

Ordering raw materials and components is a crucial yet complex process in the manufacturing industry. It involves accurate calculations of quantities that often require comprehensive knowledge and expertise. While counting components might be relatively straightforward, materials often present more of a challenge due to their different quantities, like length. For instance, calculating the exact amount of metal profiles, wire, pipes, and other similar materials can be particularly complicated.

We’ve been getting these questions from many OpenBOM customers. In the blog today, we are going to provide two examples of how you can capture raw materials from the SOLIDWORKS project and count them in OpenBOM.

The goal of this process is to streamline raw materials estimation, making it more efficient and accurate. OpenBOM, a robust and comprehensive Bill of Materials (BOM) management platform, provides a seamless way to extract data from CAD systems, calculate the total quantity of raw materials, and make orders based on inventory gaps.

Using OpenBOM with SOLIDWORKS

OpenBOM offers a robust mechanism to extract data from CAD systems such as SOLIDWORKS. It captures these raw materials in a variety of ways, calculates the total quantity, and helps make orders based on inventory gaps. Here, we provide two examples of how to capture quantities using OpenBOM with SOLIDWORKS.

Using Weldments Assemblies and Pre-calculate Quantities

This approach involves calculating quantities within the SOLIDWORKS system before capturing them using OpenBOM. In SOLIDWORKS, you can compute the exact quantity of each material required for a particular project. Once the calculations are complete, you can then use OpenBOM to capture these quantities and create an accurate BOM. This BOM can then be utilized to order the exact amounts of each material, reducing waste and ensuring that you have all the necessary materials on hand.

Mapping Raw Material To Quantity in BOMs

The second approach is to map the Length from raw materials to BOM Quantity and use Flattened BOM to roll up in OpenBOM. In this method, the total length of a particular material used in a project is calculated, mapped to quantity, and added to the BOM. This method is especially useful for materials ordered by length, like wire or metal profiles. It provides an accurate count of the amount of material needed, reducing over- or under-ordering.

To better understand these methods, please refer to the explanatory videos. They provide a step-by-step guide on how to calculate and capture quantities using OpenBOM and SOLIDWORKS, making your material ordering process more efficient.

Video Tutorials

Watch the following two videos to make the calculation explaining how you can use both methods I described above- weldment assembly and length quantity mapping.

Pre-calculated raw material size from weldment assembly:

Mapping Length to Quantity property:

Conclusion

Capturing component quantities and raw materials is a tedious process that requires accuracy and time. The complexity of this process can divert the focus of engineers from the design aspect of a project to dealing with reporting. Also, manual capture of information such as component size (eg. length) can be prone to errors and can cost money later in the process.

OpenBOM, with its seamless integration with CAD systems like SOLIDWORKS, provides a solution that streamlines this process, enabling engineers to focus more on design and less on data capturing.

Furthermore, OpenBOM significantly expedites the development process by facilitating quick and accurate data transfer to procurement. Procurement can then use accurate reports via BOMs to make orders based on inventory gaps, reducing waste, saving costs, and ensuring efficient production. By leveraging the capabilities of OpenBOM, manufacturers can optimize their raw materials ordering process, enhancing overall operational efficiency.

REGISTER FOR FREE and check how you can make precise automatic raw materials calculations and automate the purchasing process.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.