The question about Part Numbers, schemas and the way it will be organized and managed are always the topic that drives a lot of debates and misunderstanding. Although it might be a thing that easy – it is just a number you identify a part, an assembly or an entire product, it impacts in many ways how manufacturing organization is organizing processes and communicating. New parts, change orders, manufacturing process, maintenance, support. All these processes are involving Part Numbers to identify and actions to be made. Depending on how processes and systems are organized, a company may consider that a specific numbering schema or way to organize can be better.

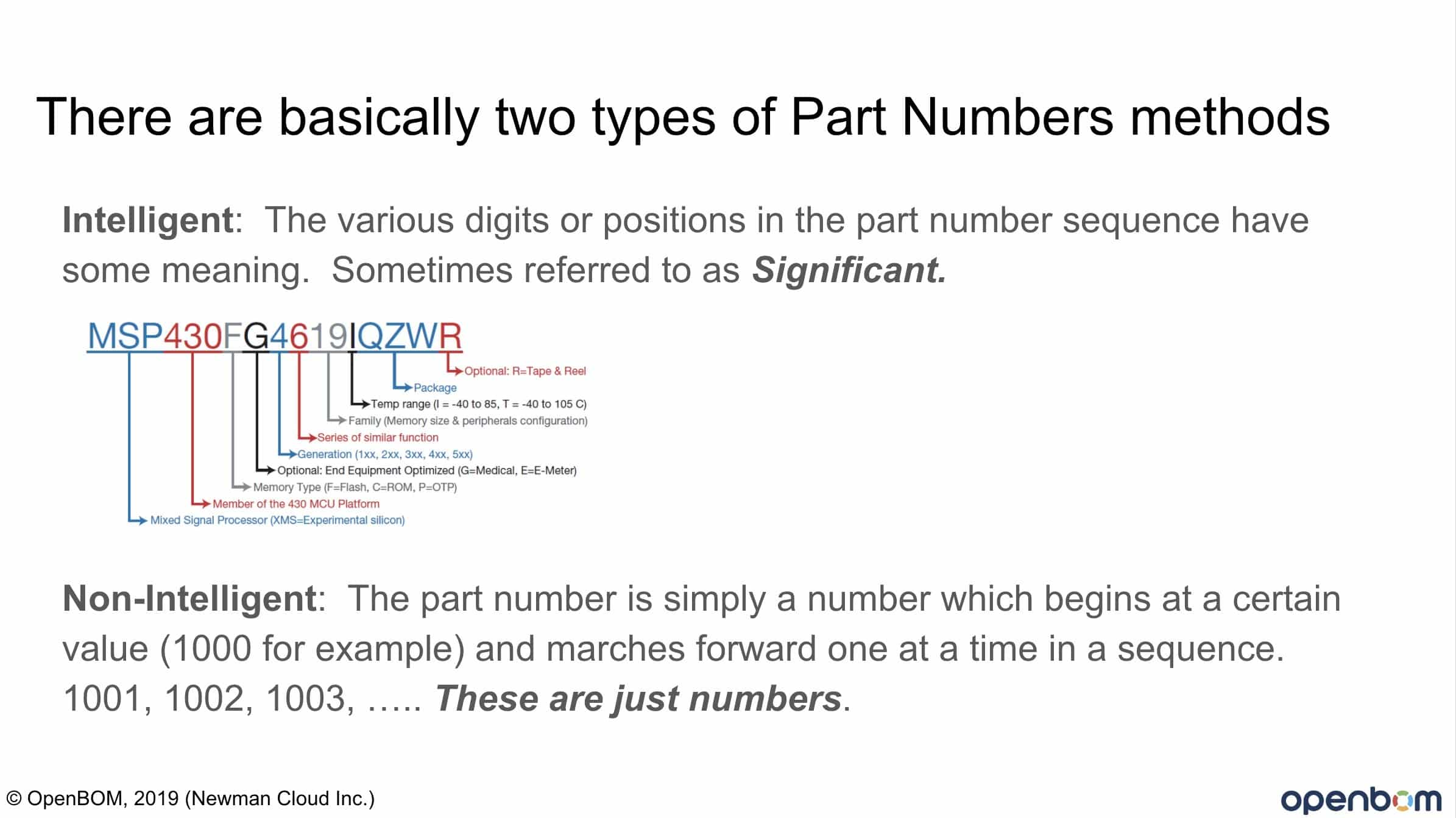

Earlier this week, our OpenBOM Educational Webinar was about Part Numbers. It focused on the main dilemma – to use dumb numbers for Part Numbers or use sophisticated intelligent numbers combined from multiple elements – numbers, codes, and prefixes.

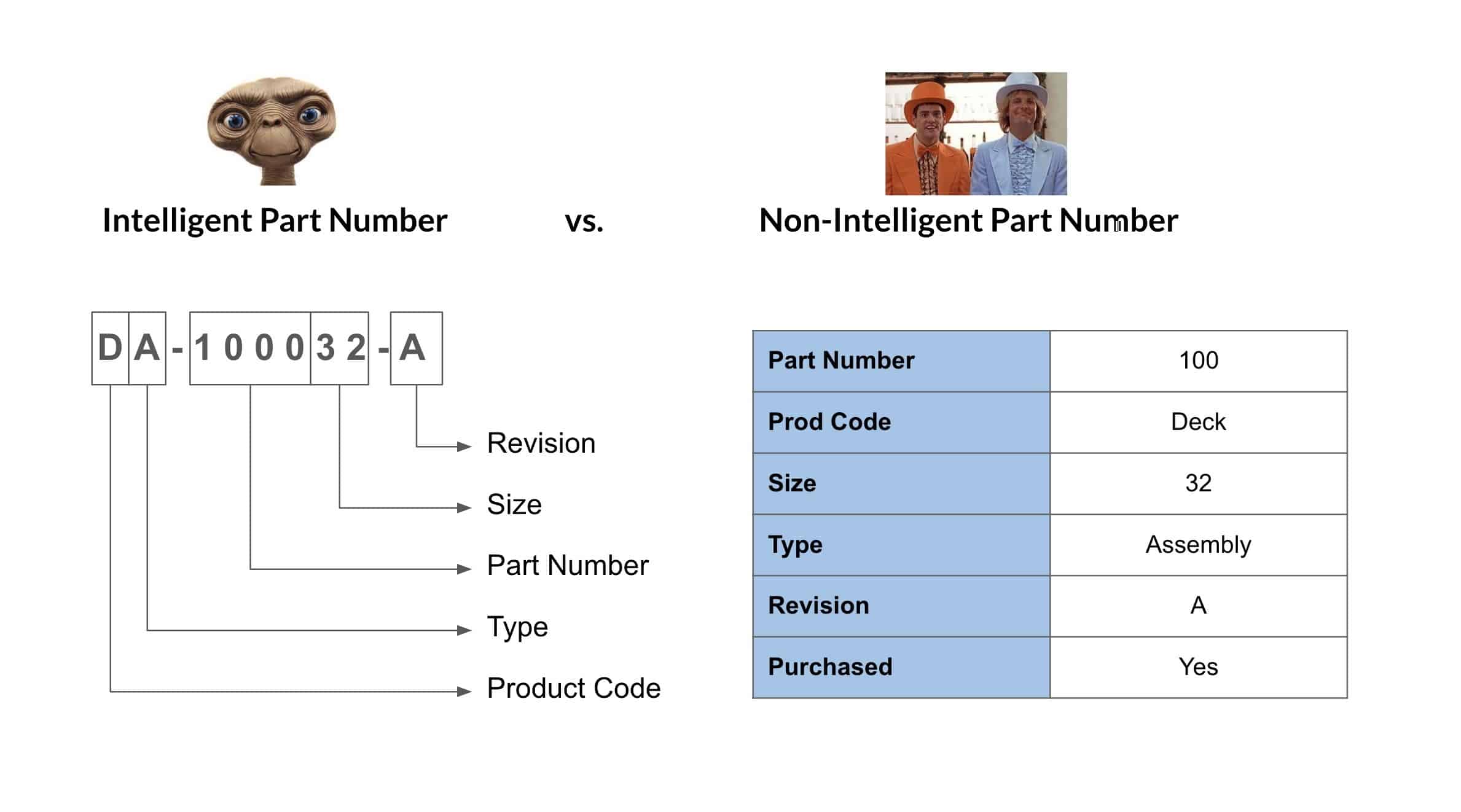

Here is a dilemma in a nutshell.

The following video of the recording of the webinar. It is a 30 min video, but I highly recommend it to you.

And if you’re interested in slides, you can find them here.

BOM Management Webinar: Part Numbers – Intelligent or Just Numbers? from Oleg Shilovitsky

Intelligent numbers

Pro: Allow items to be easily recognized by their PN, often they may move through a process like change control faster. It may be easier to search for and find in digital systems. Comfortable and familiar with team members.

Con: Maintenance of the part numbering system is an ongoing (costly) activity. Adding a new product code or other metadata to meet the needs of an unanticipated part category can be expensive and time-consuming.

A simple change to a part may cause a part number change!! It can be very expensive to propagate that change through a product structure!

Just numbers (not dumb, but efficient)

Pro: Easy. Fast. Literally no maintenance of the part numbering system. Easy to “dispense” the next part number without analyzing or knowing the properties of the part. Little institutional knowledge required. Low training demands. Lower cost.

Con: Requires a flexible and organized open system to manage BOMs and product structure. In order to be useful, related part information (metadata) must remain associated with the part number and be retrievable by all members of the extended enterprise.

Conclusion

Part Numbers are heavily influenced by the history of the company. Once it is done in a manufacturing company, the Part Numbering schema is something that very hard to change. Therefore, it is something you need to consider very carefully.

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? PLM or Product Lifecycle Management starts from the information and is an essential concept to pay attention to. Product Life Cycle in OpenBOM Aa the product information is a foundation of design, planning, and manufacturing, you should learn how to manage PLM efficiently? Check out my Beyond PLM blog and PLM Book website

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.