PLM and ERP are two major business systems in every manufacturing company. Traditional distribution of work between these systems was established for the last few decades leaving PLM to focus on engineering and product development and ERP focusing on logistics, finance, and inventory management.

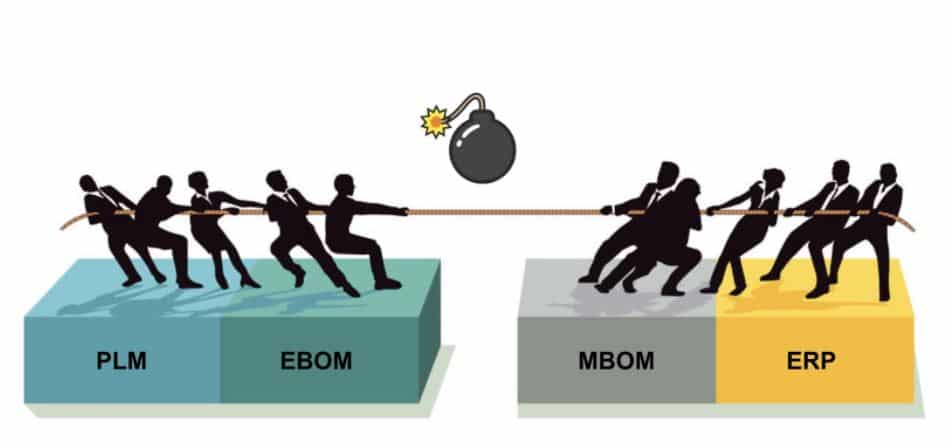

PLM vs ERP Debates

If you follow my publications on my Beyond PLM blog, you have probably seen a series of articles which started from PLM vs ERP Tug of War, which attracted a lot of attention and triggered many comments and discussion. If you have time, I highly recommend you to follow comments in the discussions on LinkedIn – it is a great source to learn from real practitioners about integrated PLM and ERP processes. Check the comments here and here.

My favorite comment came from Jos Voskuil, my long-time PLM colleague, which I crossed paths with many times since we’ve been working together at SmarTeam and later at Dassault Systemes.

A topic (PLM vs ERP) that always creates a lot of attention and it should not be. Most organizations are locked in silo thinking with systems per silo. Starting to analyze the optimal flow of information and who is accountable for which data elements is the goal. On purpose, I talk about accountability of data, not ownership, as ownership sets the mind to thinking in systems.

Integrated Product Development Information Flow

The key reason and the reality of why the topic of PLM and ERP generates so much interest and debate is because the information flow process is really complex. At the same time, integration is a priority of manufacturing companies’ demand. And to have a good process integration between engineering and manufacturing is always a challenge.

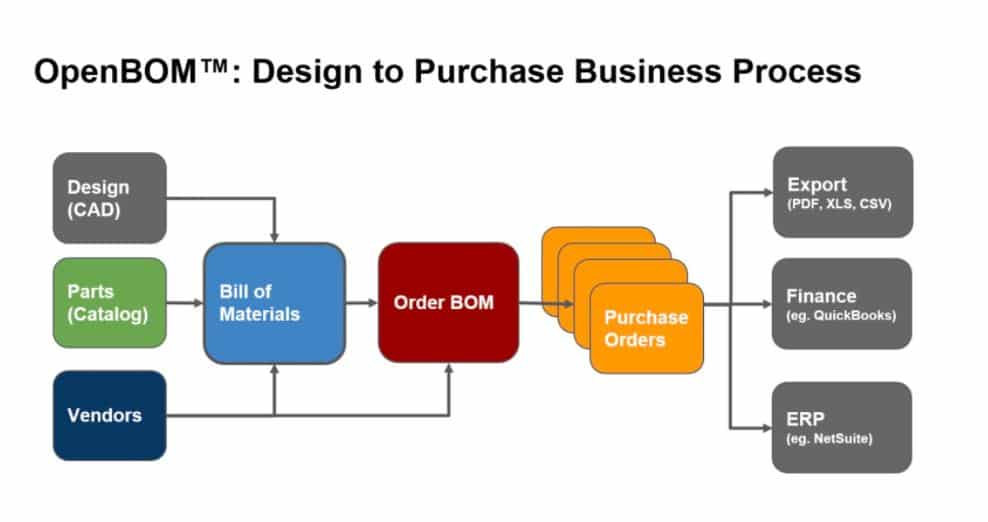

To provide engineering to manufacturing process integration was on the top of our mind when we created the vision of OpenBOM, which connects engineers, production planners, procurement, contractors, and suppliers. At OpenBOM, we wanted to create a unique platform capable of providing integration between engineering production and procurement.

Here are 3 elements that make OpenBOM valuable to companies and teams looking to integrate the PLM+ERP process:

- Flexible Data Model capable of managing item master and information combined with product structure (Bill of Materials) with multiple views

- Deep engineering system integrations capable of seamlessly integrating with CAD and other systems used in product design and development

- Integrated production and purchasing planning capabilities which allow basic inventory control and procurement planning.

In addition to these three unique solutions, OpenBOM’s technological and business platform is based on modern cloud and SaaS capabilities which allow companies and teams to bring together two fully-fledged solutions – PLM and ERP. No longer does your journey of integration have to be complex and costly.

Check the following articles for more information about OpenBOM Design To Purchase process and integrated Production Planning and Inventory Control. Customer Experience Speaks for itself

Check out OpenBOM customer’s stories and online reviews on G2 Crowd where customers speak about how important it is to have an integrated way to organize the information flow and to run the company business using OpenBOM.

Here is what John Ellerbrock, California-based Gates Underwater Products, the manufacturer of the world-class underwater photography equipment says about their OpenBOM experience – Gates Underwater Products Uses OpenBOM To Connects Design Engineers, Manufacturing and Supply Chain Teams Together.

OpenBOM is our single source of truth,” says John. “ We have one location for parts catalog, COGS, inventory management, and assembly BOMs. All in OpenBOM, which has an intuitive and easy-to-navigate interface. Creation and update of BOMs are driven from within the Solidworks environment, so the link is always preserved and synced. Someone in purchasing can open the BOM in OpenBOM and see the exact product and know what to buy.”

“We are moving steadily toward running the business on OpenBOM. It just works the way we want it to work. Naturally, and as a long-established company, we have a large backlog of existing products so migration to OpenBOM takes a systematic approach. In the end, we will have a fully digital representation of our products in Solidworks and OpenBOM”

My favorite thing about OpenBOM is “it is right-sized for my company. Filling a niche that MRP systems are not. Other programs are too limited or cost too much. OpenBOM offers a lot of benefits to a company in a certain range and at a great value.“

Another story from Pierce Workholding, developing innovative best-in-case manufacturing equipment – Pierson Workholding Is Using OpenBOM For A Complete Design To Manufacture In-house Process. This is what Carlos Acosta, a chief problem solver at Pierson has the same demands when choosing a Bill of Materials management solution – which is why he chose OpenBOM:

“We looked at a lot of options for creating and managing Bill of Materials, the CAD-based product didn’t have the ability to create Planning BOMs and Purchase Orders (which we need) and Excel didn’t have any connection to our design process (CAD), which we also required,” says Carlos. “OpenBOM offers a complete Design to Purchase process which includes BOM, Order (planning) Planning BOMs, Vendor Lists and Purchase Orders. As well as inventory control of Quantity on Hand”

Conclusion

PLM and ERP as it is today are too big to serve agile product development and manufacturing teams. The small and midsize businesses are the natural target for unique integrated solutions capable of bringing a combination of SaaS platforms together with CAD integrations, engineering BOM, inventory management, and procurements. However, size doesn’t always matter. We can see the demand for such solutions coming from agile teams focusing on new product development in large industrial companies.

Check out what OpenBOM can do for you today – REGISTER FOR FREE and start a FREE 14-day trial.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.