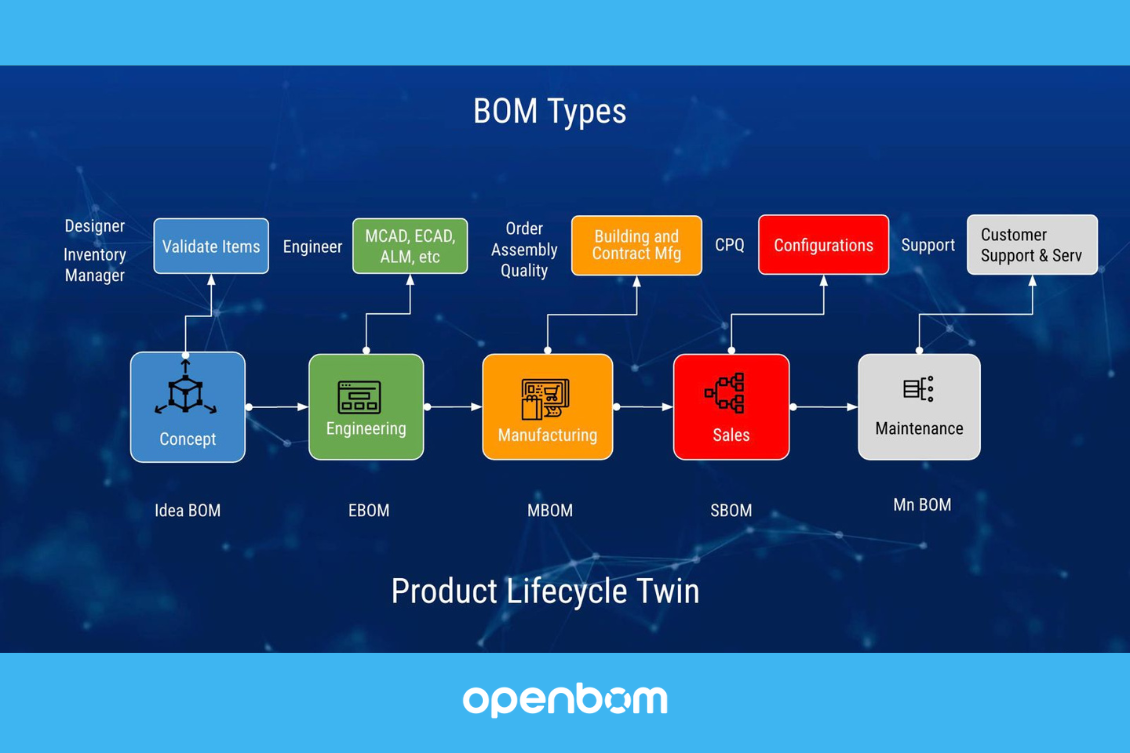

OpenBOM recently released its xBOM service, a powerful tool that opens up vast opportunities for building different BOM types, providing a diverse and comprehensive set of information about a product. If you missed our previous publications, we’ve included links for you to check out the details. xBOM’s flexible structures allow for a range of BOM configurations, which can sometimes be overwhelming. In this blog, we’ll guide you through various examples of BOM types, demonstrating how you can effectively manage each within OpenBOM.

Simple BOM: The Basics

A Simple BOM is your starting point—a straightforward list of components needed to build a product. This type of BOM includes the basic information: part numbers, descriptions, quantities, and potentially a few other attributes. It’s an essential tool for any manufacturing process, serving as the foundation for more complex BOMs. With OpenBOM, creating and managing a Simple BOM is seamless, allowing you to quickly assemble the necessary parts for production.

Engineering BOM: From CAD to Reality

The Engineering BOM (EBOM) typically originates from the CAD system and reflects the design intent of the product. It includes all the components, assemblies, and sub-assemblies as designed by the engineering team. EBOMs are crucial for ensuring that the product is built as designed, with all necessary parts and specifications in place. OpenBOM’s xBOM service makes it easy to integrate your EBOM directly from your CAD system, ensuring data accuracy and consistency throughout the product development process.

Manufacturing BOM: Organizing for Production

The Manufacturing BOM (MBOM) is organized with sequences, components, and orders to facilitate the production process. Unlike the EBOM, which is focused on design, the MBOM is focused on the manufacturing process, including information on how and when parts should be assembled. This BOM type is critical for production planning and ensuring that all necessary resources are available when needed. OpenBOM’s flexible data model allows you to create an MBOM that aligns with your specific manufacturing processes, ensuring a smooth transition from design to production.

Support and Service BOM: Keeping Track of Products in the Field

The Support and Service BOM is designed to track serial numbers, spare parts, and service procedures. It’s vital for maintaining products after they’ve been sold and ensuring that customers receive timely support and service. This BOM type includes detailed information on each product’s configuration, making it easier to identify the correct parts and procedures for repairs or upgrades. OpenBOM’s xBOM service enables you to maintain a comprehensive service BOM, helping you keep track of all necessary details throughout the product’s lifecycle.

Functional BOM: Focusing on Sub-Systems

A Functional BOM focuses on specific subsystems of a product, such as the electrical sub-system or software components. This type of BOM is particularly useful for complex products with multiple interdependent subsystems. By organizing the BOM around functional areas, you can more easily manage the development and integration of each sub-system. OpenBOM’s xBOM service allows you to create functional BOMs that provide a clear view of each sub-system component and their relationships, facilitating better collaboration and system integration.

Here is an example of an electronics BOM.

Another example of software BOM that is getting more important these days with the growing amount of software integration in manufacturing products.

Video Demo

Watch the video of all these BOM Type variations and learn how OpenBOM can be used to manage a diverse set of information about the product across multiple systems and lifecycle stages.

Conclusion

There are many BOM types that you might need to manage throughout the product lifecycle. OpenBOM gives you a flexible and robust infrastructure to manage these different BOMs effectively, ensuring that all aspects of your product’s design, manufacturing, and support are covered. Whether you’re working with a Simple BOM, an Engineering BOM, a Manufacturing BOM, a Support and Service BOM, or a Functional BOM, OpenBOM can help you implement best practices and maintain a comprehensive set of information about your product.

REGISTER FOR FREE to start a trial and explore how OpenBOM can help you manage different BOM types with ease.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.