In the modern industrial landscape, it is critical to create a robust digital business foundation, with a particular focus on product data. The focus on management of product data, bill of materials (BOM), and asset information stands as a critical element for businesses spanning diverse sectors.

Whether your operations involve the production of complex machinery, the running of a manufacturing facility, or the oversight of expensive equipment, the capture and organization of product information throughout its entire lifecycle form is the key element of operational efficiency.

Manufacturing companies are switching their business models from selling products to selling services. It brings the question of connecting engineering and maintenance information into connected digital threads.

In my blog today, I will dig into the importance of these critical data elements and bring some examples of how businesses can transform their operation using OpenBOM to seamlessly connect product and asset information.

The Importance of Capturing Product Information Across the Lifecycle

Comprehensive Understanding: To effectively manage any product or asset, it’s essential to have a detailed and granular understanding of its lifecycle. This includes its design, manufacturing, maintenance, and retirement phases. By capturing data at each stage, you gain valuable insights into how the product evolves and can make informed decisions.

Optimized Maintenance Operations: Properly organized product data allows for optimized maintenance operations. You can track when specific components need maintenance or replacement, reducing downtime and increasing overall operational efficiency.

Mitigate risks: Monitoring product data throughout its lifecycle helps ensure product quality and mitigate supply chain risks. You can identify and address maintenance issues early in the process, plan maintenance operation and secure critical supply of components to prevent outages of equipment and costly recalls.

Complex Products Require Granular Data Management

Complex products, such as machinery, factories, or buildings with sophisticated equipment, demand a granular approach to data management. This means capturing and connecting different types of information assets, including assembly data, product specifications, and maintenance records.

OpenBOM: A Flexible Data Management Solution

OpenBOM is a robust online data management platform that helps to organize data from multiple sources. Its flexible data model allows you to customize information organization on every level, making it an ideal choice for managing complex products and assets. What else, OpenBOM data management and collaboration capabilities allow us to connect complex product information with full detail levels with suppliers and contractors.

Here are some key features of OpenBOM:

Customizable Data Model: OpenBOM enables users to customize data models according to their specific needs. This means that even in the case of complex products, you can adapt the system to suit your unique requirements.

Data Integration: OpenBOM can seamlessly integrate data from various sources, ensuring that you have a unified view of your product’s information. This integration streamlines the data collection process, making it easier to manage assets efficiently.

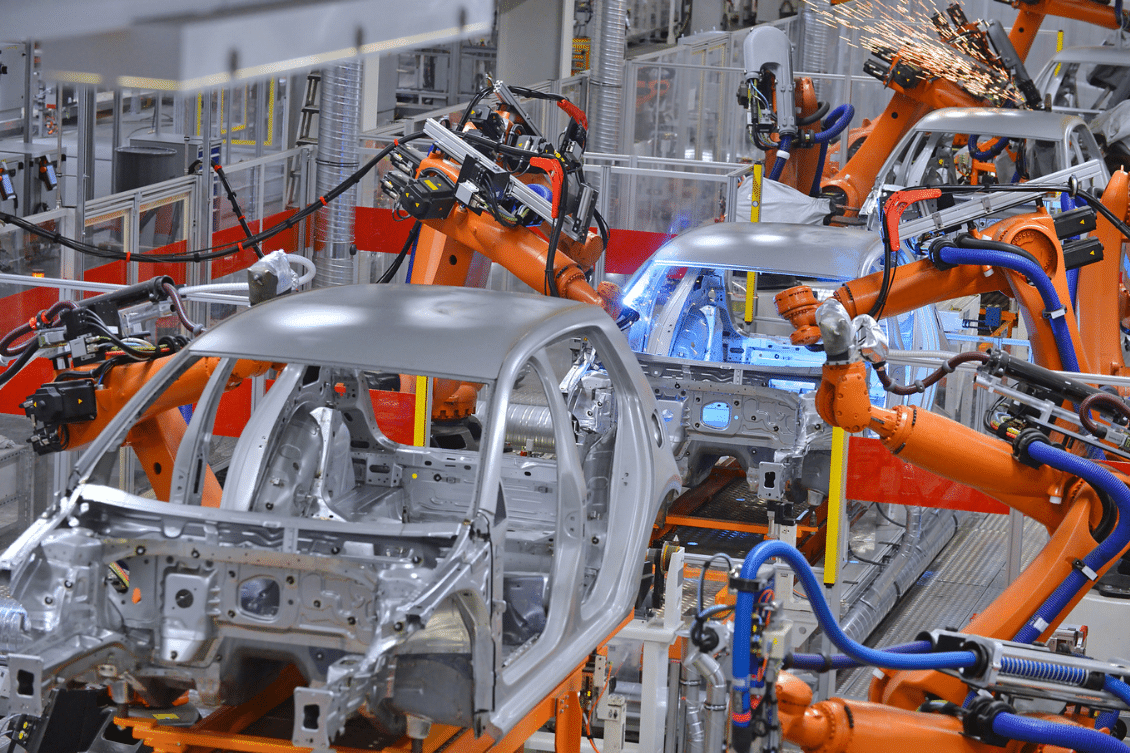

Example: Magna Steyr Fahrzeugtechnik AG

I’m attending AU 2023 this week. OpenBOM is partnering with Autodesk which allows it to build robust data integrations to pull data from multiple sources – Assemblies, Factory Assets, product and supplier data.

To illustrate the effectiveness of OpenBOM, let’s look at an example from Magna Steyr Fahrzeugtechnik AG. The following example of using OpenbOM to pull a bill of materials for the factory assets combining factory assets and assembly information, including all components.

By doing so, they can maintain a comprehensive overview of their complex products, making it easier to manage their assets effectively.

Conclusion: The Foundation of Digital Business

In conclusion, robust data management is the foundation of a successful digital business. It allows you to organize a multi-disciplinary set of information, collect, organize, and track complex product data, and optimize maintenance operations. Whether you’re dealing with complex machinery, factories, or intricate building equipment, capturing and managing product data, bill of materials, and asset information is essential for staying competitive and efficient in today’s business landscape.

In a world where data drives decisions and operations, OpenBOM provides the flexibility and functionality needed to excel in managing complex products and assets. It can lead to improved efficiency, reduced downtime, and ultimately, a more successful and competitive business.

REGISTER FOR FREE and experience OpenBOM first hand.

Have a complex asset management project? Contact our sales team today – we would be happy to help you.

Best regards,

Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.