You’ve made a great design for a new product. Or you’ve made a new feature for an existing product. These things are exciting, but by far not enough to make turn this product into a reality. The reality can be messy as going from design to assembly requires you to go through the many steps such as production planning, purchasing, and assembly.

And this is a place where companies are either using expensive ERP systems or turning your heads to a massive Excel-ware. In my life, I’ve seen many companies running inefficient purchasing processes using Excels to calculate how many parts need to be purchased, working long evening hours creating purchase orders and at the end running out of screws or overpaying for the deliveries.

OpenBOM helps you to solve this problem by supporting a simple design to the purchasing process. Check more our documentation for production planning.

These are the basic steps:

1- Create and manage catalog(s) of items everything – assemblies, parts, etc.

2- Create and manage vendor list – these are companies you’re making orders from.

3- Create and manage Bill of Materials

4- Create an Order BOM and generate Purchase Order.

Today, I want to focus on one very painful moment of this process. It is related to the management of Purchased Assemblies in Solidworks and creating of Bill of Materials for these assemblies.

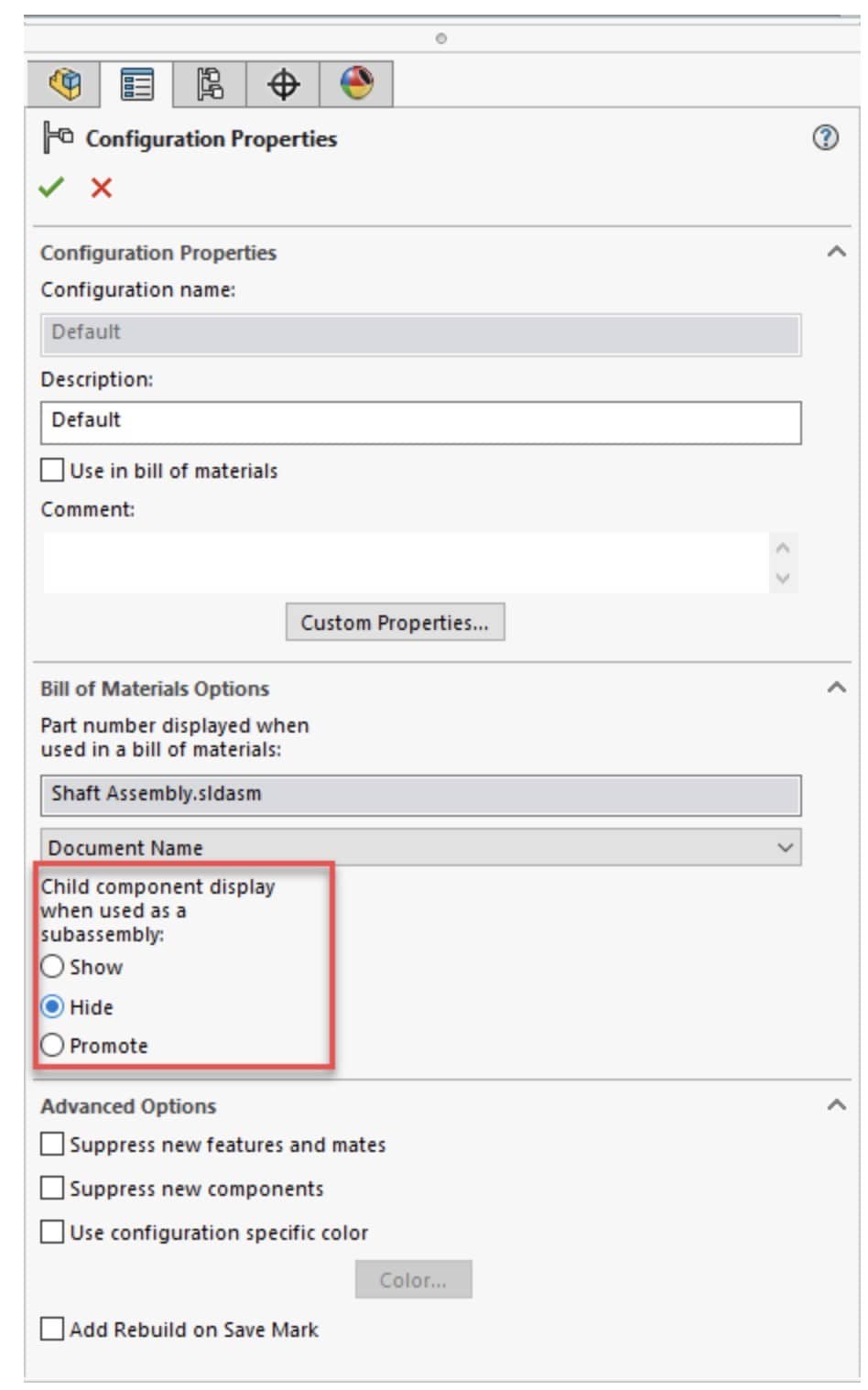

In a nutshell, here is a typical problem. You need to have a purchased assembly (eg. Electrical Motor) with all parts in your Solidworks design, but to include only top-level assembly in the BOM.

I have a piece of very good news for you. Since the last update of OpenBOM add-in for Solidworks, we have the full support of child components display options. Here are how these settings will be used:

This is the image to remind you how these options can be set in Solidworks.

- Show (Solidworks default) – show/include all sub-items in the BOM

- Hide (purchased assembly workflow) – do not include sub-items in the BOM

- Promote (the phantom assembly workflow) – do not include the assembly and move all sub-items to the upper level

In the following video, you can see a short demonstration of how the child component display option can be used to create a BOM with purchased assemblies from Solidworks directly in OpenBOM. Please check this out.

Conclusion.

The new Solidworks add features are making the next level of improvement in the way how OpenBOM intelligently extracts data about the design and turn it into Bill of Materials that can be used to run the purchasing process.

Check this out – OpenBOM Solidworks Add is available for all OpenBOM subscriptions. Register here.

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.