Are you considering implementing OpenBOM in your organization? In the world of product lifecycle management (PLM), OpenBOM represents one of the easiest-to-use systems and intuitive user experience, but even so, it is still a system with a rich set of features and some of them requires planning, settings, and configurations.

It is important to educate your organizations about how OpenBOM is managing information and prepare your team to start using OpenBOM. Earlier we posted an article that speaks about the 3 Do’s and Don’ts of OpenBOM Onboarding. It is a great source of information that can actually help you to get prepared for the training session with OpenBOM specialists.

Today, I want to take a step back and talk about what preparation you need to make before even committing your organization to implement OpenBOM. I’d say these questions are probably also good for preparing your organizations for any PLM implementation. Although, I’ve made them with OpenBOM examples to make your life even easier.

Every change in an organization (even if it is a good change) is some sort of disruption that requires your team to re-think the way they work and sometimes get rid of bad habits, even if you’ve been doing it for a long time.

Here are my 5 topics to discuss with your team to get ready to implement OpenBOM PLM.

Product Development Process and Data You Need To Manage

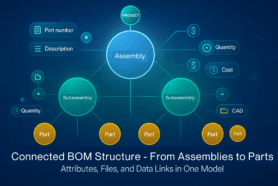

The first thing you need to think about is your company’s development process, its organization, and how data must be managed in your organization. The foundation of every OpenBOM implementation is the data we manage – CAD files, items, product structure, and related information. Thinking about how to capture this information in your current environment, how you manage it now, and what needs to be improved is essential to have a successful OpenBOM implementation. I recommend you start with some simple data sampling – assemblies, item data, manufacturing vendors, contractors suppliers and think about what data you need at every stage.

How OpenBOM will support your company’s business processes?

Business is the first priority of every company. Therefore thinking about your current business process and what challenges you have is important to have a successful OpenBOM implementation and improve your processes. I recommend you think about the top 5 business priorities and challenges you have. Bring them up and connect them to the data and processes you plan to manage in OpenBOM. It can be anything – bad file version control, inability to manage BOM revisions, poor cost management, or communication with contractors. Aligning business with technology is essential to have a successful implementation.

How to manage OpenBOM implementation success

There are two main things that will help you make a successful OpenBOM PLM implementation – (1) agile implementation phases; (2) performance KPIs. It is absolutely important to organize the implementation as an agile-phased process. Don’t try to get everything done at once. You won’t make it. You need to plan steps to implement OpenBOM and get your company to adopt it step by step. Once you get some initial implementation done it is time to think about how to manage the most important KPIs that help the performance of your system (eg. time to create data, making a change, cost saving, procurement mistakes, etc. ). Altogether it will help you to measure the success.

How you will manage all company product data using OpenBOM

OpenBOM PLM is as good as your ability to create a single source of truth for all product information. It is essential that your OpenBOM database will holistically manage all information – all catalogs, all BOMs, all vendors, etc. Don’t treat OpenBOM as “better Excel” reporting, but think of it as a place where all your data lives. Your implementation is as good as the catalogs you build in OpenBOM. Connect all information to items in catalogs and manage the entire product lifecycle using Items.

Is there a need for integration with other enterprise and engineering software?

An important step in OpenBOM PLM implementation is to plan if you need to connect OpenBOM to other engineering or enterprise systems. The main advantage of integrations is to eliminate manual data handover. Each time you re-type (re-enter) the data, you have a chance to introduce a mistake or miss some information. The end goal of your OpenBOM PLM implementation should be seamless information flow in your organization.

Conclusion:

Changes are hard. Even if you run a very badly organized process, it is still a process your organization is regular to have and everyone feels “ok to do so”. Once you bring a new system, you need to set up new processes, document them, and follow them, which might require some effort. If you make all preparations I described above, your company will be prepared also from the standpoint of how to use OpenBOM and how to measure the results of data management and process improvements.

REGISTER FOR FREE and check how OpenBOM can help you and your team today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.