When managing Bills of Materials (BOM) in OpenBOM, data creation is often a repetitive and time-consuming task. One such task is the addition of new items to a catalog. However, OpenBOM offers a handy feature that lets you do this seamlessly without having to leave the BOM screen. In this article, we’ll walk you through this streamlined process.

Why is This Useful?

The ability to add an item directly within the BOM screen might seem trivial, but when you’re adding multiple items, the time savings can add up significantly. Consider this: if you save 2-3 minutes each time you add a new item, the cumulative time-saving could be substantial, especially for extensive BOMs.

How to Simplify Data Creation with OpenBOM:

OpenBOM Catalog Management: Begin by using the OpenBOM catalog to manage your items. Although it’s not obligatory, configuring your Part Number settings can make the process more efficient.

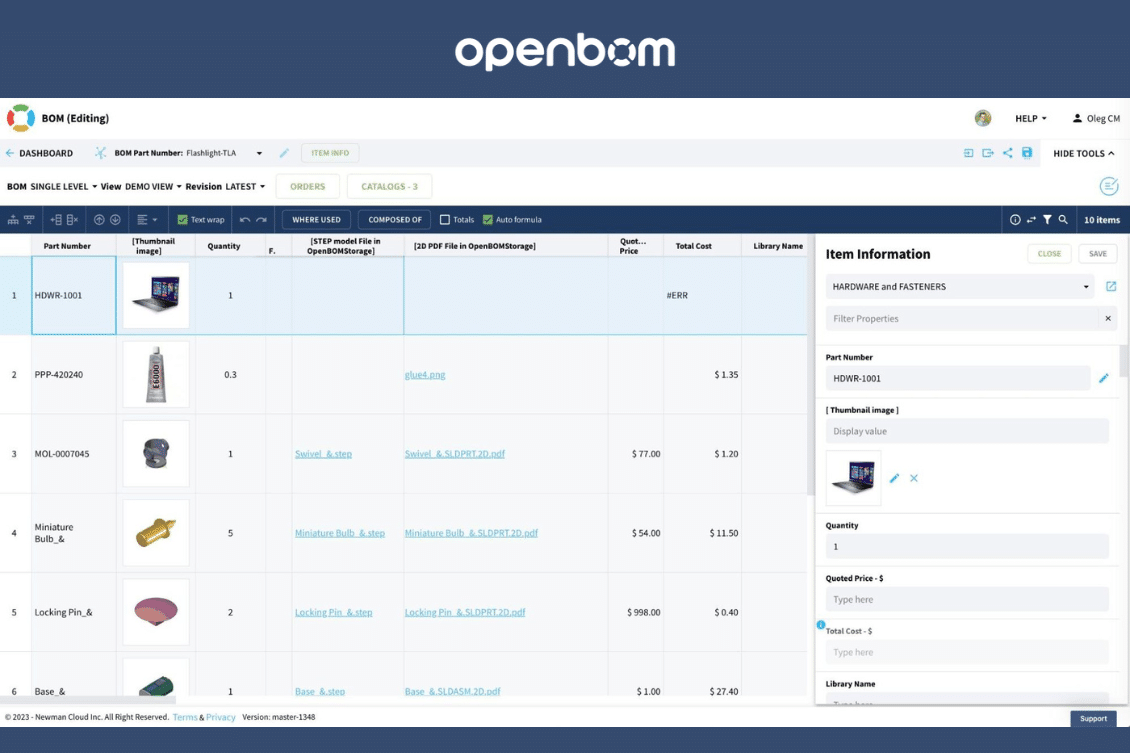

(1) Adding a New Item: Once in your BOM, add a new item. You’ll notice an empty line where the new item will reside.

(2) Item Info Panel: Next, open the Item Info panel to view and modify details for the new item.

(3) Part Number Command: Within the panel, select the option to edit the new item’s Part Number and generate its unique Part number

(4) Fill Out the Properties: Once you’ve generated the Part Number, fill out the necessary properties for the new item

(5) Save: Finally, hit the ‘Save’ button. And voilà! Your item will now be added to both the catalog and the BOM with just a few clicks.

Watch the video to see how it works:

What is the best Item creation method

There are multiple ways to create an item in OpenBOM – add it to a catalog, import it from Excel, save it from CAD, or add it from a BOM as I demonstrated above. Each method is good for a specific scenario. This one is good when you need to create an item seamlessly during the BOM creation process.

- Fewer Clicks: The streamlined process means fewer clicks, resulting in faster data entry and reduced chances of errors.

- Seamless Workflow: By organizing tasks in a way that they can be executed from a single screen, OpenBOM allows for a more seamless workflow.

Conclusion

At OpenBOM, our aim is to simplify and enhance the user experience. It’s the little things—like seamlessly adding an item to a catalog from the BOM screen—that make a big difference. Whether you’re a first-time user or a seasoned expert, our platform is designed with efficiency in mind.

Want to experience these features for yourself?

REGISTER FOR FREE and begin your free OpenBOM trial.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.