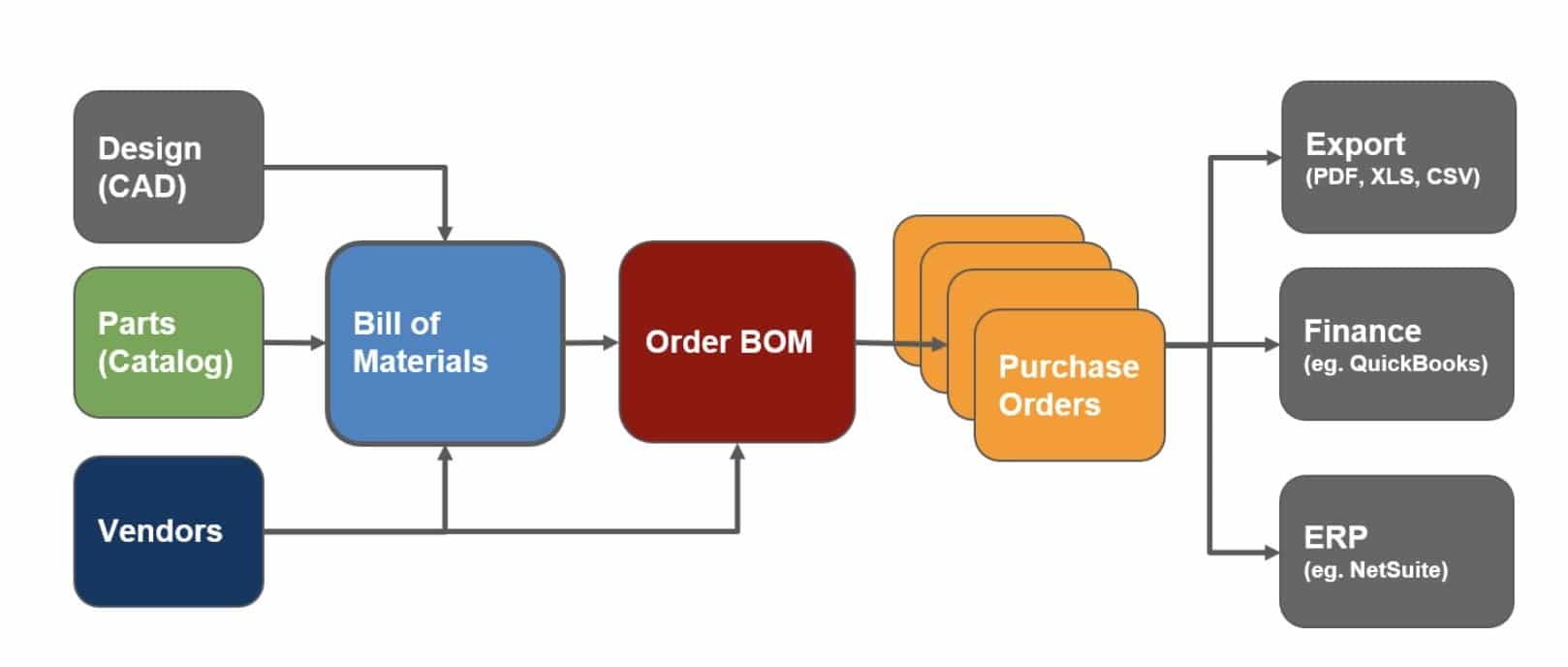

Production planning can be thought of as the process, end-to-end, of using your BOM to buy the parts you need. The goal of the purchasing process is to create purchase orders that can be used to order standard components and sub-contractors’ work to build the product. Think of them as documents your company will be sending to vendors.

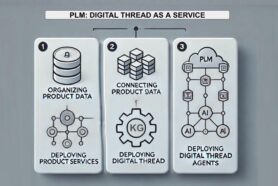

Check out how the top-level process looks in the diagram below. The diagram will give you an overall perspective of how data is flowing between each of these data objects. While the diagram takes you from the design to purchase order, keep in mind that the process is iterative and includes returns to BOMs, catalogs, and order BOMs as the maturity of the product increases. After all, manufacturing is never linear. You build an initial product, build prototypes, improve the design, fix changes, and finally create a product description (including OpenBOM management bills of materials of the product that can be shipped.)

We are starting a set of webinars to discuss the buying process. This is Part I in a short series of webinars dedicated to the age-old problem of buying parts. Specifically, how do we quickly go from a “design” to getting parts in the door? In Part I, we will learn the proper setup of Item Master Catalog(s), Vendor lists, managing inventory levels with Quantity on Hand, and understanding quantity gaps. Please send your questions ahead of time to support@openbom.com.

Wed, Oct 14, 2020 2:00 PM – 3:00 PM EDT

Back to Basics: The Design through Purchase Process

Conclusion

The Bill of Materials is a single version of the truth about your product as well as an ultimate source of information that can be used to purchase parts and order outsource work with contractors and suppliers. We are going to discuss a set of best practices on how OpenBOM can help you to manage the purchasing process.

Best, Oleg @ openbom dot com.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website. Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.