Design collaboration is key to success in the manufacturing industry. However, many companies are still using outdated methods for design collaboration. This can lead to missed opportunities and can impact the bottom line. PDM systems aimed to help designers and engineers to collaborate.

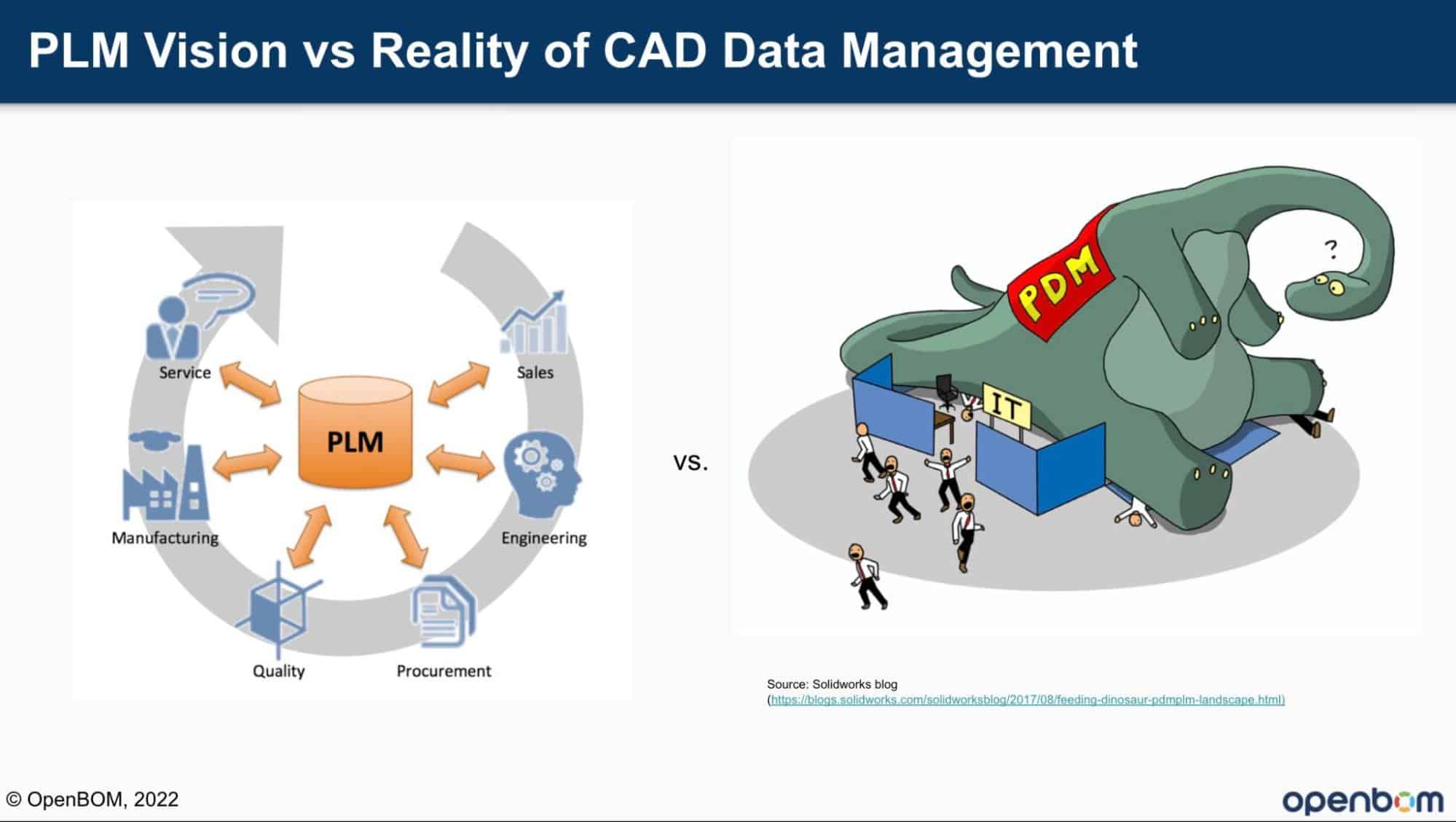

PDM always was a big promise. It had their success stories, but many more failures. Complex PDM systems that hard to configure and expensive to implement is a reality of CAD/PLM world.

Collaboration is becoming even more important these days. For the last two decades, CAD, PDM, and PLM vendors were working on how to improve the collaboration between team members, contractors, and suppliers. The importance of collaboration is growing tremendously throughout the last few years because of the following two main reasons:

- Complexity is growing (more people need to be involved in the design, planning, and manufacturing)

- Processes are becoming more distributed (we are not working in the same building anymore).

The development of cloud systems opens a lot of doors that can help engineers, partners, and contractors to collaborate. However, there is one big problem – files. As much as we move forward in CAD development, and create modern design systems that allow to engineers collaborate, files are still one of the biggest problems. Files were born many years ago and most of the existing CAD systems are (still) using files to store and share data. Files are an insanely popular paradigm and it is very hard for engineers to change it. New systems are replicating the files paradigm with a new collaborative user experience and new data management. But there is still a super large number of customers that are using (and will be using files) as a means to store and exchange data.

Replacing existing desktop CAD systems can take another 10-20 years and in the meantime, we need to invent technologies that can help engineers work together while still using existing CAD systems and managing information using the file systems.

PDM system challenge

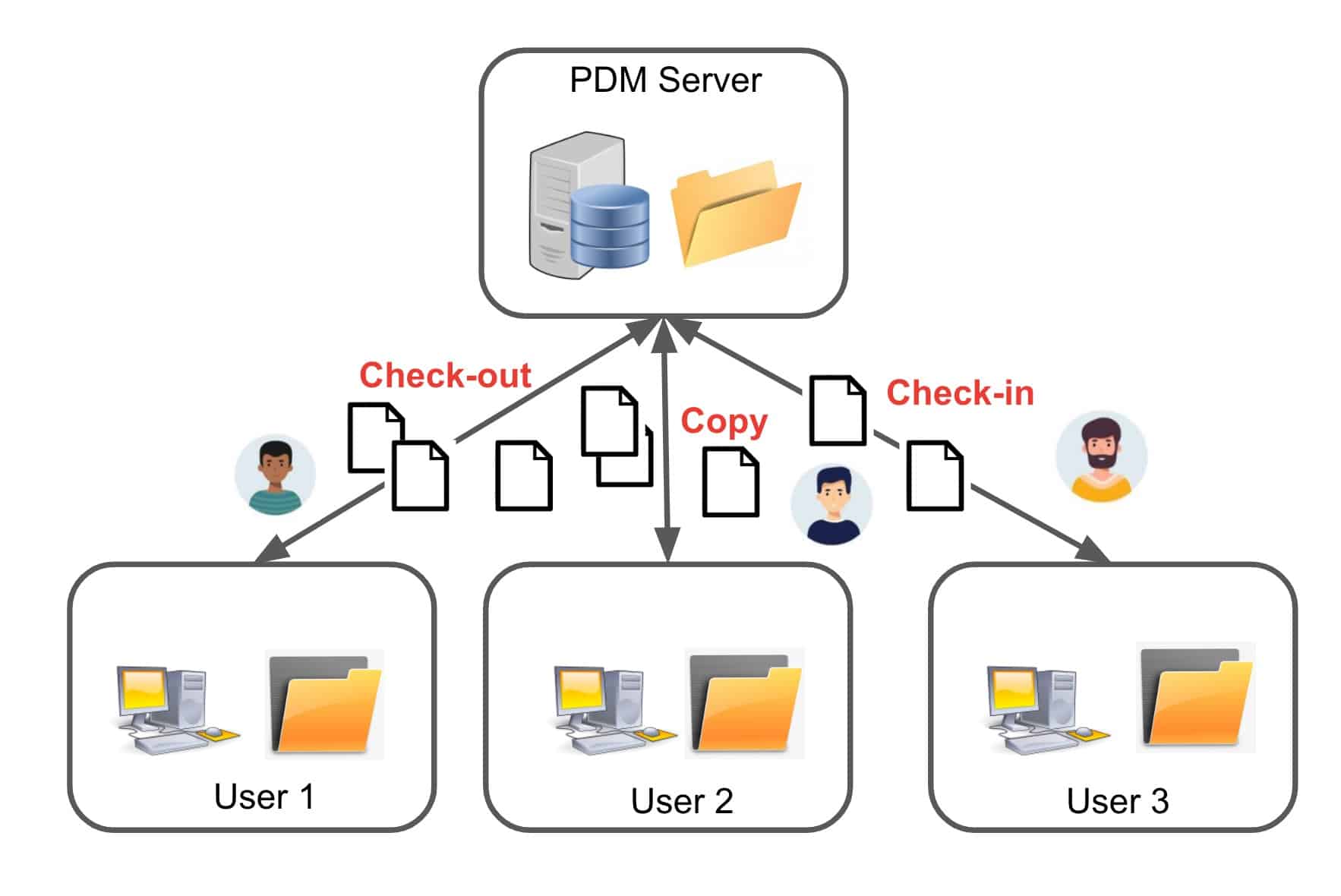

The biggest data management for the PDM systems for the last two decades was file management. PDM system invented a centralized Vault system that can hold files protected and allows users to check out/in files from that vault to make controlled changes. The entire process is cumbersome and complex, prone to errors, mistakes, and slowness. Each local computer is using a copy of the files to work on and it is the responsibility of engineers to bring files back to the central vault storage. If someone doesn’t do it, everyone will be using an old (not updated) file. When a new file is updated in the central vault, it is responsible for an engineer to copy it to a local file system in order to use the updated files. The picture below speaks for itself.

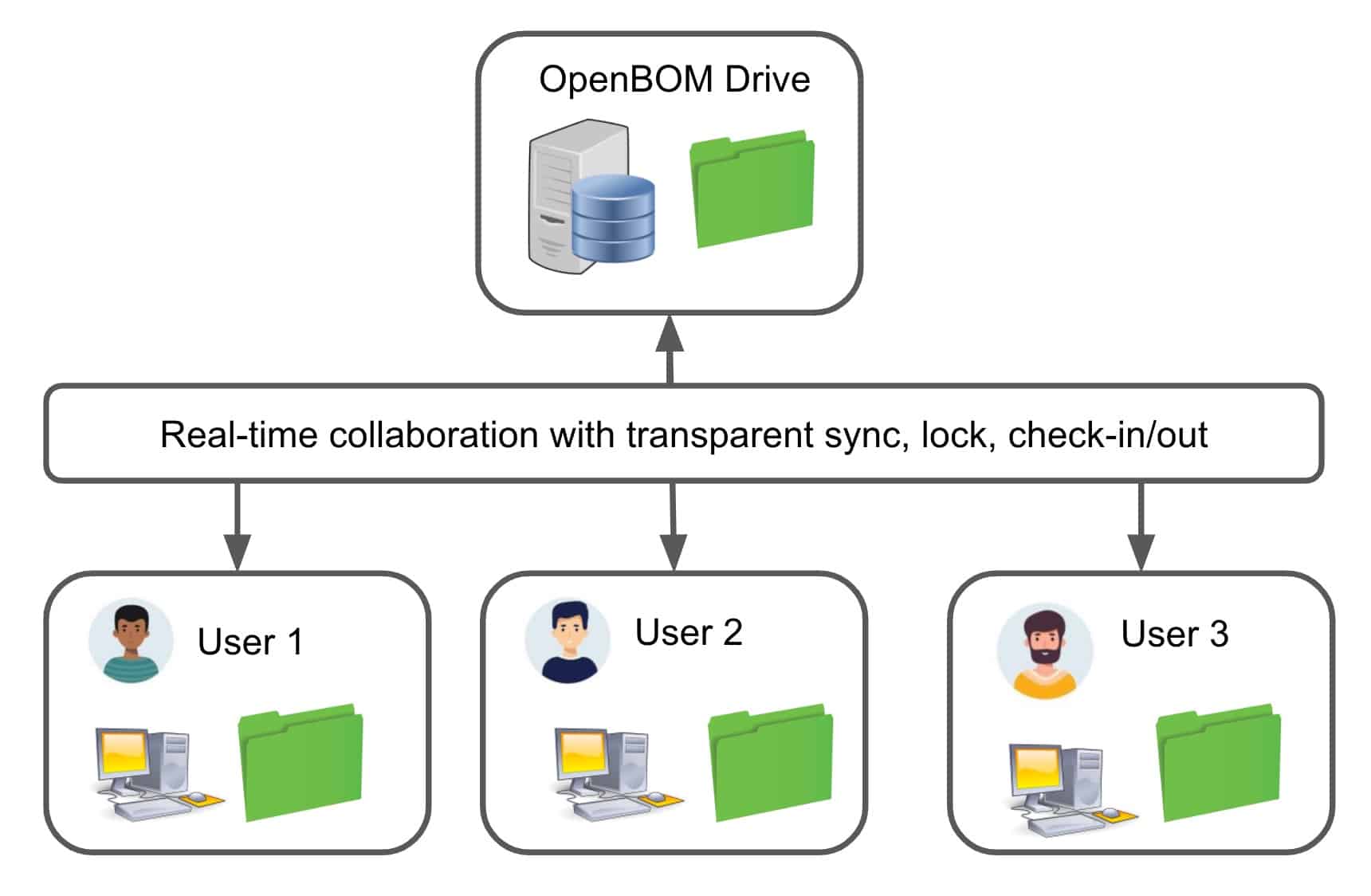

How OpenBOM Drive Is Different

Here is the difference between a traditional PDM system and services provided by OpenBOM Drive. Instead of copy files between the Drive server and local folders, Drive is a system that seamlessly provides an access to centralized storage and allows everyone to work on the same file. An automatic or manual locking system allows users to lock files (check-out) and release the lock (check-in), which creates a file version.

Connecting Data In a Digital Thread

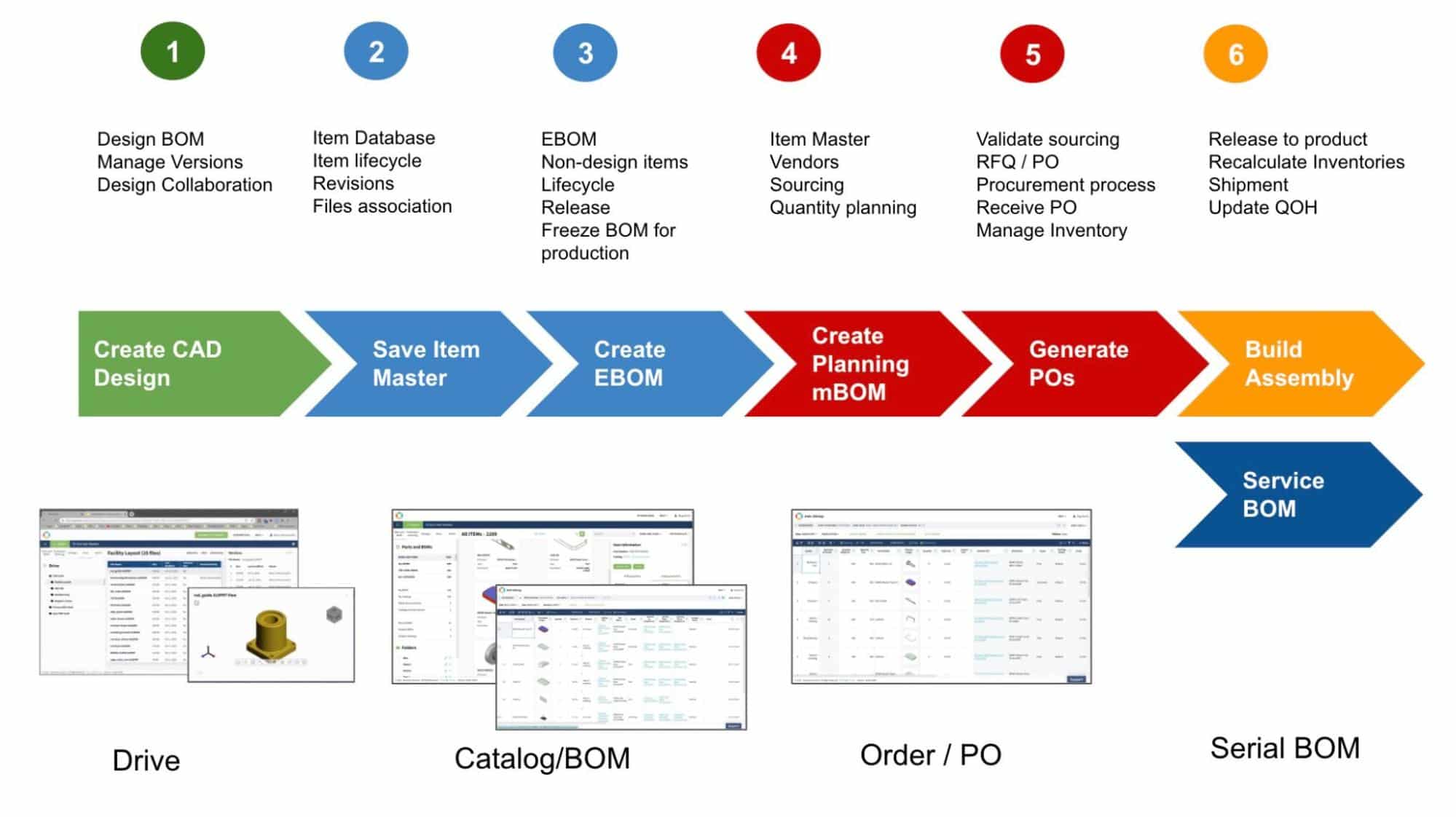

Drive services are integrated with the rest of OpenBOM services and functions to support a continuous lifecycle, data management, and collaboration between designers, engineers, production planners, purchasing departments, and other people involved in the process of product development.

Drive manages design versions that are used to capture items and bill of materials data, manage BOMs, support product planning, and perform a seamless data handover between engineering and manufacturing.

Conclusion

OpenBOM Drive services provide a way for engineers to manage files and stay connected with all information and changes in a seamless way. Drive functionality doesn’t require engineers to perform tedious manual copy and check-out/in operations, to ensure that files are copied from a central location to a local folder to perform their design work. Instead, OpenBOM Drive provides a seamless way to keep data in sync and support real-time collaboration. At the moment of time, any engineers working on files make a change and save the file, the file changes are seamlessly kept in sync and available to everyone else without any manual operations.

REGISTER FOR FREE and start a free 14-day trial to check out how OpenBOM can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.