In today’s global economy, manufacturers are constantly searching for ways to reduce costs and improve their margins. One way to do this is by outsourcing production to a third-party supplier. While this can be a great way to save costs, there are challenges with lead time, tier 2 & 3 supplier pricing, planning, and more. Dealing with the complexities of modern-day manufacturing and the dependencies of the supply chain is difficult. In this post, we will look at the challenges involved with procuring parts for your contract manufacturer.

One of the greatest values of working with a contract manufacturing partner is to leverage their supply chain network. This means you don’t need to source each individual sub-assembly and part for your product. You work with one supplier and they procure all of the parts on your behalf.

However, there are times in which a manufacturer procures parts for their contract manufacturer (CM) and delivers those parts to their facility. The most common reason for this is because they can get the part cheaper than their CM can, or because they have an existing relationship with a supplier.

Whatever the reason is, you need to think of whether or not it’s worth it. Is it worth the extra complexity and stress to procure parts by yourself?

Why Would you Procure Parts for your CM?

There are a number of reasons why you would want to procure parts for your CM.

Lack of Suppliers for a Particular Material or Parts

A common reason why a manufacturer will provide a part to their CM is that their CM lacks a supply chain for a particular material or sub-assembly. While a CM does have a vast network of suppliers, it might not have certain suppliers for certain parts or materials.

Pricing

Your CM should provide you with a full bill of materials (BOM) quote. From there, you can identify items that are too expensive. If you have worked with suppliers that can be more cost-effective then you might want to purchase those parts by yourself.

Long Lead Times

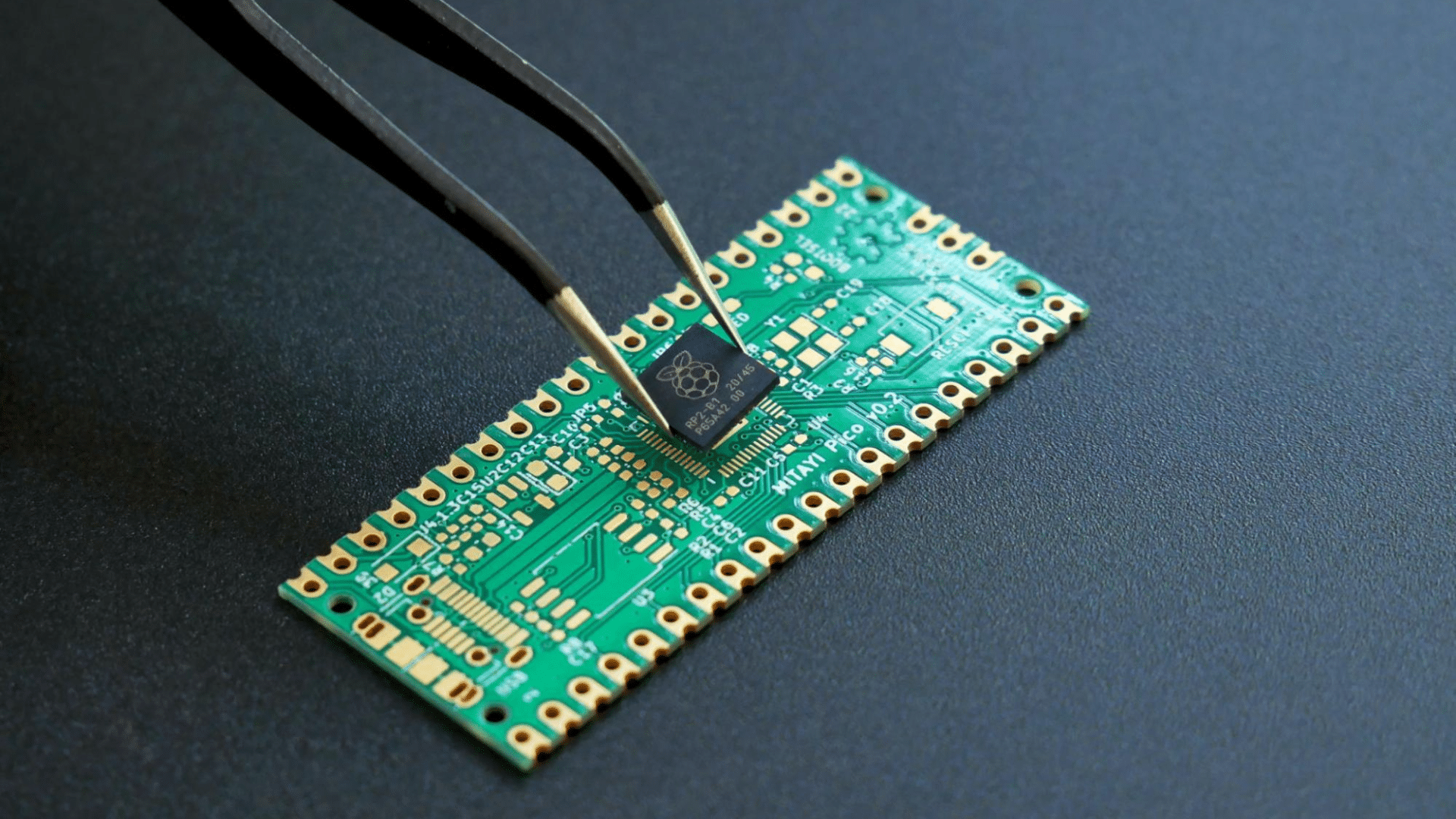

It is common for manufacturers to purchase electronic components well in advance due to the chip shortage. A manufacturer will also procure parts on their own if any of the items on the BOM have a long lead time that pushes back the anticipated shipment date.

Risks of Purchasing Parts for your CM

If you are purchasing parts and sending those to your CM then you are adding a layer of complexity to your supply chain. While adding these complexities, you also risk your CM being less enthusiastic about your product.

Usually, your CM will add a procurement fee to the parts or sub-assemblies that they procure for you. The added fee is usually 5-30%. If you start to source parts on your own then you are taking revenue away from your CM. If the dollar value is large enough then you can see other costs increase, such as your assembly costs or inventory/holding costs.

There are also a few other risks you need to think about if you want to procure parts from another supplier.

Quality Problems

If your CM is procuring your parts, they will accept responsibility for the parts that come from their supplier. If there are quality problems then the CM will take responsibility for those quality problems and solve those quickly. If you supply the parts, you might not see quality problems being dealt with and solved as efficiently.

Payment Terms

Your CM might have 10 different payment terms with all their suppliers they need to manage. However, your CM makes it simple for you by providing you with just one payment term. If you procure additional parts, you need to worry about managing multiple different payment terms.

Poor Communication

Whenever you add a new party to a relationship, things can get confusing. Your CM might not be willing to speak with them making you become a middle man between the two parties.

How to do it the Right Way?

While there are risks of procuring parts for your CM, it can also be done successfully. The best way to do this is to be transparent with your CM about why you are doing this. Then you would want your CM to add the supplier to their approved vendor list (AVL).

If your CM adds them to their AVL then they will be responsible for all quality problems, they will manage all the payment terms, and they will be the ones leading communication.

Purchasing parts directly for your CM has a lot of risks associated with it. But, suggesting they add your supplier to their AVL can work very well.

How Can OpenBOM Help?

OpenBOM improves the process of how you work with your CM, contractors, colleagues, and other team members. We provide you with the capabilities to seamlessly manage your parts, vendors, bill of materials, purchase orders, and change orders. All BOM, engineering, and manufacturing information is stored in the cloud which you can share with anyone.

If you need to improve the way you manage your data and processes, contact us today for a free consultation.

Regards,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.