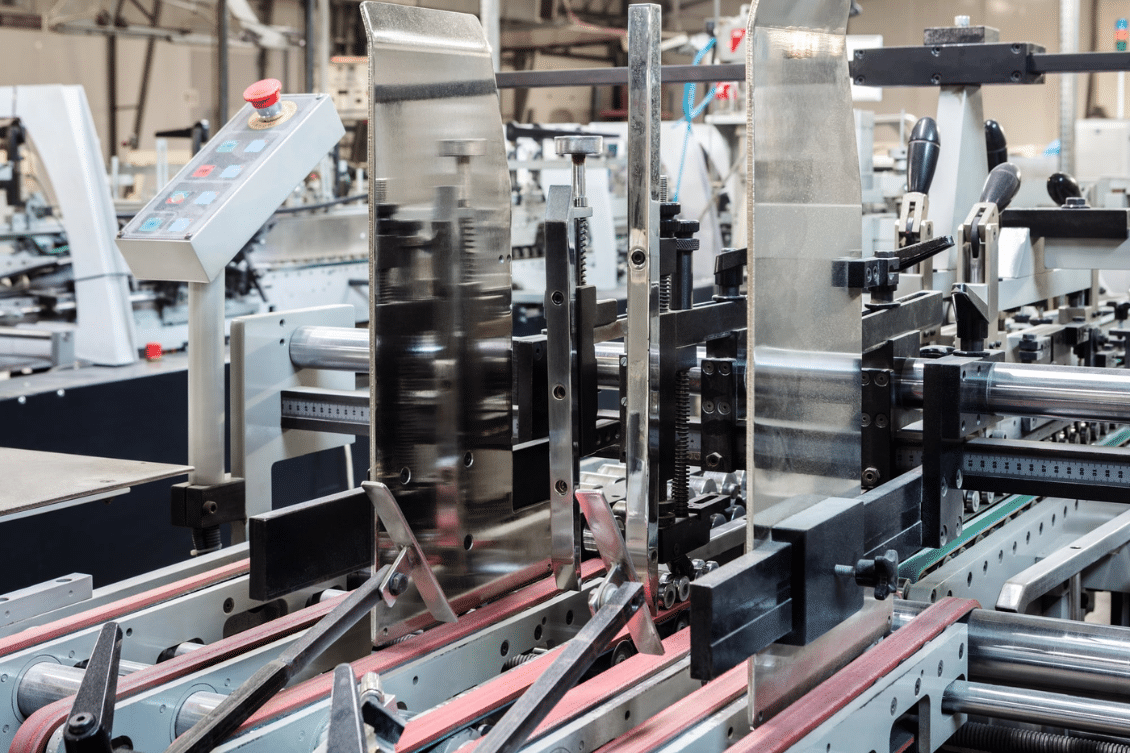

Building complex products requires more than just creating a good product design. It is about coordinating the design activity with planning, production, and supply chain. Complex machinery, industrial equipment, high-tech, and electronics are examples of industries that demand high-level complexity and tools support for multi-disciplinary design teams, coordinating with contractors and suppliers connected together. A traditional approach of making a 3D design using tools like Solidworks and throwing it over the wall of manufacturing won’t work anymore. Today, I want to talk about how we help these types of customers using OpenBOM tools integrated with Solidworks MCAD and other design tools.

Building Better, Faster, Cheaper: A Holistic Approach

In the fast-paced world of product development, efficiency and innovation go hand-in-hand. SolidWorks has long been a staple for engineering teams in designing complex electromechanical products. However, the real challenge lies in connecting the dots – Design, Bill of Materials (BOM), Purchasing, and Assembly. This article delves into how engineering teams can leverage OpenBOM to streamline these stages, breaking down information silos and fostering collaboration.

The process in the picture above is slow and disconnected, which needs to be optimized. 3D Design is disconnected from all other steps.

Bridging the Disconnect: From SolidWorks to a Unified Process

SolidWorks offers an exceptional user experience for design, but it’s just the beginning of the product development journey. The disconnect between the SolidWorks desktop environment and the rest of the product development chain is stark. Critical elements like BOM, purchasing, and assembly often exist in isolated information islands, scattered across various locations.

A typical process is to take Solidworks design and export information into files and folders converting BOM to Excels and CAD files to STEP, PDF, and DXF files. It is a slow manual process. The solution? A connected process that brings these disparate elements together.

OpenBOM: The Link That Binds

As discussed in a previous article, OpenBOM offers a way to seamlessly capture SolidWorks data. It simplifies the continuous integration of this data into the broader product development process. OpenBOM’s strength lies in its ability to continuously, simply, and rapidly capture and integrate data from SolidWorks.

The data is automatically captured and updated in OpenBOM. It can be seamlessly available in Solidworks, but at the same time be accessible to all other participants of production planning and procurement processes.

From Design to Deployment: The OpenBOM Advantage

Once the full product structure, along with all related information, is loaded into OpenBOM, it becomes a powerhouse for other stages of the product development process. Whether it’s cost estimation, sourcing, procurement, or purchasing, OpenBOM equips teams with the necessary tools right out of the box.

This comprehensive approach ensures that all aspects of product development are interconnected and easily manageable.

Organizing the New Product Development process through OpenBOM allows for seamless integration with the SolidWorks environment. This integration brings together production planners, procurement teams, contractors, and suppliers in a cohesive workflow. The picture below shows how OpenBOM helps to connect all the stages and stakeholders together.

The real magic of OpenBOM is in how it extends the reach of SolidWorks data beyond the engineering department, ensuring that every piece of information is accessible and utilizable in downstream processes.

Conclusion: OpenBOM’s Transformative Impact

OpenBOM’s seamless integration with SolidWorks allows data to flow more freely and earlier in the process. This early availability of comprehensive data enhances the quality and accuracy of decision-making support across the board. In summary, OpenBOM doesn’t just support SolidWorks users; it revolutionizes the way they connect, collaborate, and create.

REGISTER FOR FREE and learn how OpenBOM can help. The Team at OpenBOM is happy to help.

Best,

Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.