In today’s rapidly evolving landscape of engineering and manufacturing, the seamless integration of design data is critical for the efficiency and accuracy of decision-making. OpenBOM, a leading platform in digital thread management, continues to enhance its capabilities to provide engineers and manufacturers with a comprehensive solution for managing engineering data.

As such, OpenBOM uses a flexible data model to automatically capture information coming from multiple sources (eg. CAD system, online catalogs, procurement, etc.). OpenBOM seamless integrations with CAD systems help to organize a design digital thread connecting design information and parameters (sizes, models, materials, etc.) to downstream procurement and production functions.

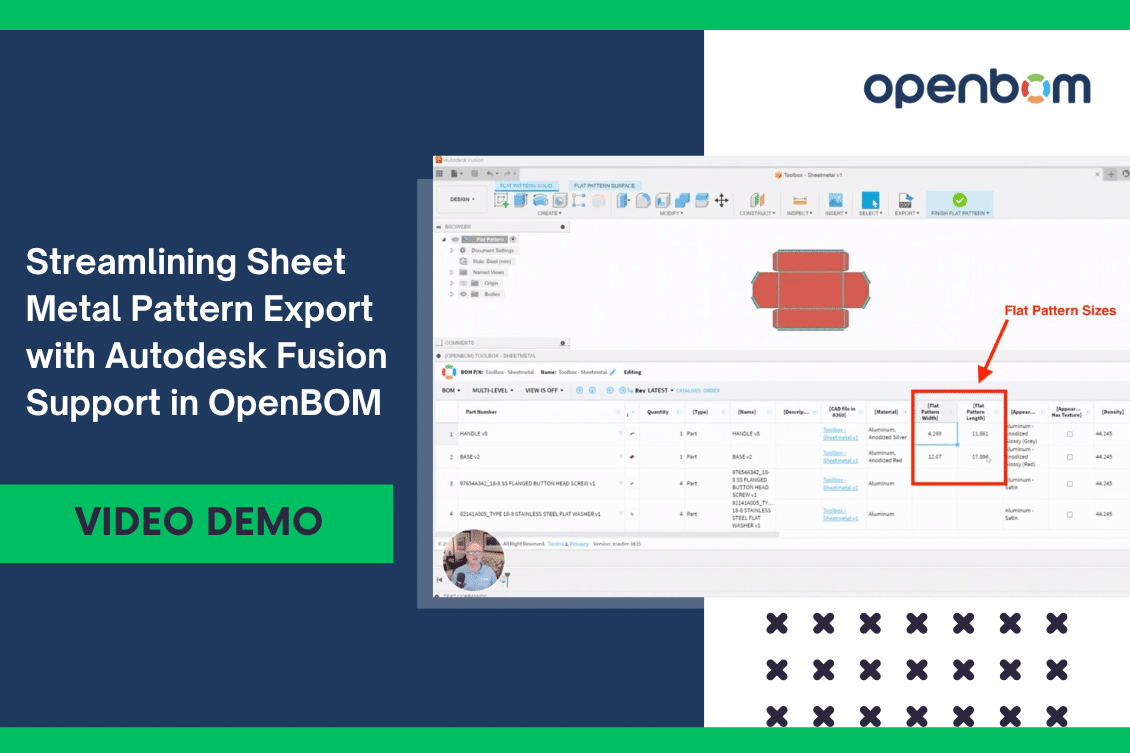

In this article today, I’d like to share a new enhancement: the support for flat sheet metal pattern export in Autodesk Fusion.

Manual Data Exports Are Hard

The challenge of manual data extraction is hard. Even if traditional PDM systems allow you to store files, access to granular information in the right format is critical. Therefore, OpenBOM is focusing on how to get the right data and put it in the right format and context.

The importance of this enhancement cannot be overstated, particularly for those involved in developing sheet metal-based products. Whether it’s for cost estimation, procurement, or ordering, having access to accurate flat patterns is essential. Traditionally, capturing this data manually has been labor-intensive and prone to errors. Automating this process not only saves time but also ensures accuracy, making digital Bill of Materials (BOM) creation simple and easy.

Flat Pattern Export for Autodesk Fusion

With OpenBOM’s new feature, users can seamlessly export sheet metal flat patterns directly from Autodesk Fusion into OpenBOM catalogs. This means that the captured data becomes automatically available in all BOMs, ready to be utilized in various tasks such as cost calculations. By eliminating manual data entry and leveraging automation, engineers, and manufacturers can streamline their workflows and focus on value-added activities.

But how does OpenBOM accomplish this feat? The integration between Autodesk Platform Service Manufacturing Data API and OpenBOM allows for seamless data transfer, ensuring that design information is accurately captured and readily available for downstream processes. Whether it’s a complex assembly or a simple part, OpenBOM simplifies the process of extracting relevant data and organizing it into a digital BOM that can be accessed and utilized by all stakeholders.

Video Demo

Check the video below on how OpenBOM does it.

Digital Transformation and Seamless Data Access

In a world where digital transformation is reshaping industries, OpenBOM is at the forefront of driving efficiency and collaboration in engineering and manufacturing. By organizing the seamless flow of information and making data easily accessible to all participants, OpenBOM empowers teams to make informed decisions and drive innovation.

As we look towards the future, the need to streamline the capture and utilization of data will only continue to grow. Whether it’s for cost assessment, procurement, supply chain management, or production automation, having access to accurate and up-to-date information is crucial. OpenBOM’s commitment to providing a comprehensive solution for digital thread management positions it as a valuable asset for any organization looking to thrive in the digital era.

Conclusion:

The integration of Autodesk Fusion support for flat sheet metal pattern export in OpenBOM represents a significant advancement in digital thread management. By automating the capture and utilization of design data, OpenBOM enables engineers and manufacturers to streamline their workflows and drive efficiency. To experience the benefits of OpenBOM firsthand, register for free today and discover how it can revolutionize your engineering and manufacturing processes.

Best regards,

Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.