CAD system and engineering information is a core foundation of the product development process and product lifecycle management. Every company is looking for product data management and how to get data from the engineering environment to streamline and manage the manufacturing process. The data does not only belong to engineers but also needs to be available to business users to support business processes.

Making all this data available in a modern connected environment is the main goal of digital transformation and this is where digital thread begins. It helps to turn off information-siloed systems where data is only available to engineers in computer-aided design (CAD) systems but can be easily available to everyone. Let’s talk about it and discuss how OpenBOM helps Solidworks users to get aligned with a modern cloud-based data governance and manufacturing process.

The data created during the design is essential to become a foundation of the new product development process. Therefore, interaction with the CAD system and its data is extremely important to provide an efficient data management solution. In my article yesterday, I provided a high level introduction of OpenBOM for Solidworks users.

Today, I want to focus on one of the key elements of OpenBOM Solidworks support – the way OpenBOM allows you to capture Solidworks data and keep it synchronized with other teams and processes.

The Importance of Information Flow

In the fast-paced, post-pandemic world of 2023, the flow of information has become more critical than ever. While using Excel and files was a suitable paradigm back in the 1990s, today’s demands for connectivity and real-time data sharing necessitate a more advanced approach. We put a great emphasis on how OpenBOM is capable of breaking the document-only paradigm and getting the data from your Solidworks design in the most meaningful and semantically recorded ways. Which brings tons of advantages of which we’re going to talk about.

SolidWorks, a system developed years ago, is renowned for its simplicity and user-friendly experience, particularly in a Windows-based, file-oriented environment. At OpenBOM, we recognize the importance of maintaining the integrity of existing SolidWorks implementations. Our focus is on creating a seamless information bridge to SolidWorks, capturing data efficiently, and managing it with modern cloud technologies, methods, and collaboration tools.

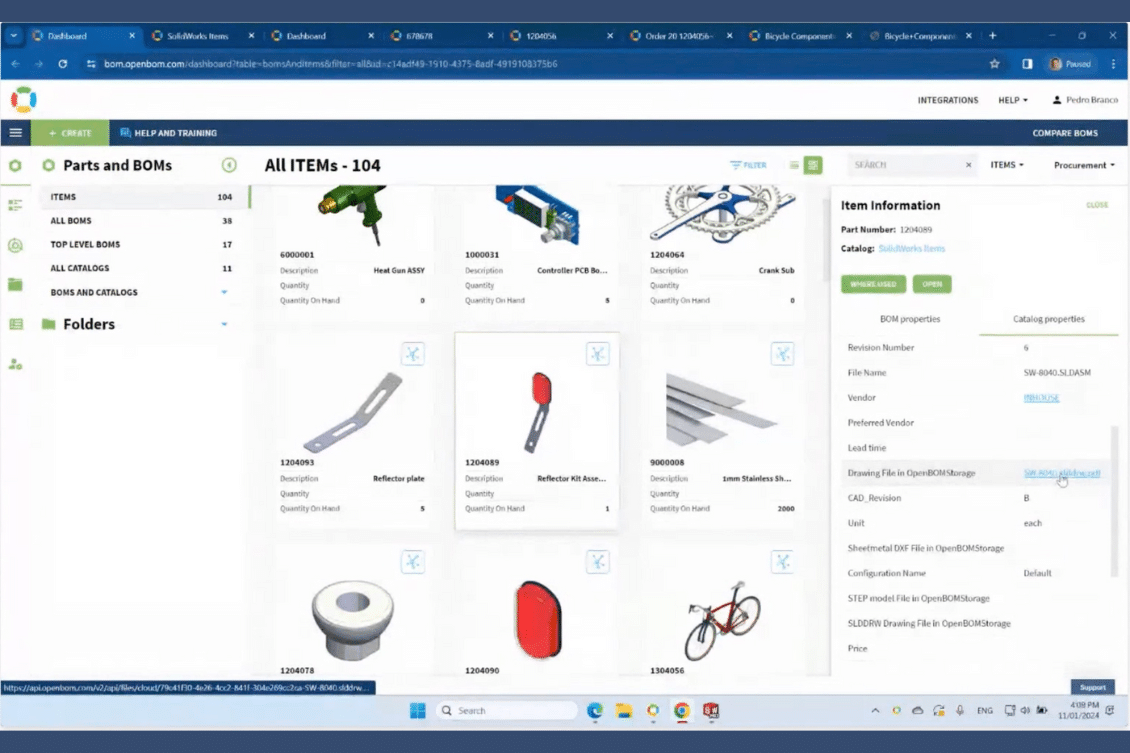

In the picture above you can see how OpenBOM is seamlessly integrated within Solidworks environment and user experience.

Configurable Data Capture and SolidWorks Settings

The OpenBOM data model is adept at automatically capturing a wide array of data from SolidWorks. This includes files, bill of materials (BOMs), quantities, derivative files, and various configurations and settings. This automatic data capture ensures that all critical information is seamlessly integrated into the OpenBOM ecosystem without manual intervention.

The following picture shows you how easily to configure capturing of any attribute to OpenBOM. Any data attribute can be easily transferred to OpenBOM.

Not only metadata and attributes but also files (both original CAD files and their derivatives – PDF, STEP, DWG, DXF) can be automatically generated and seamlessly captured in OpenBOM’s flexible data model.

OpenBOM is capable of supporting various options and settings of Solidworks to configure what components get in the BOM and what stays in Solidworks. Think about – exclude from BOM, hide/show, weldments, configurations, assembly phantoms, purchased assemblies, and others. It helps you to build the exact structure you need for EBOM directly from Solidworks.

Comprehensive Data Management in OpenBOM

Once data is imported into OpenBOM, it forms a fully defined, revision-based product structure baseline. This structure includes a complete history of revisions, enabling effective management of costs, sourcing, and supplier relationships. Additionally, the ability to add non-model items and exchange data bi-directionally with SolidWorks enhances flexibility and control.

OpenBOM bill of materials editing and other user interfaces are implemented using modern and simple spreadsheet-like user experience paradigm, which makes it very easy and simple to use.

OpenBOM advanced graph navigation allows you to explore product structure in a visual way, finding dependencies and making impact analysis.

Data Sharing and Export Capabilities

Making data really open and easily available to everyone is a big deal and OpenBOM gives you a really easy way to make data available outside of your Solidworks environment. You can automatically extract any data from your Solidworks project, and make it visual and shareable. But for all people who just need your Solidworks data in an easily digestible way, OpenBOM extends its utility by offering export options. Data can be exported to xls, csv, pdf files, and zip archives and even shared with ERP systems.

This feature allows for greater versatility in how data is utilized and integrated with other business systems.

File Management

OpenBOM is not forgetting about basics – file management. OpenBOM Design – a free cloud-based file management system that allows you to capture all Solidworks and related files into Design projects and manage their revisions and changes.

Conclusion: The OpenBOM Advantage

The seamless connection between OpenBOM and SolidWorks allows businesses to maintain their familiar SolidWorks environment without disruptions, while simultaneously extending it with modern, cloud-based tools. This integration represents a significant step forward in data management and collaboration. Check out OpenBOM and register for a free trial to experience these benefits firsthand.

REGISTER FOR FREE and see how OpenBOM can help you manage your Solidworks projects and get the engineering data you need for downstream processes in the most efficient way.

Best Regards, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.