Imagine running a manufacturing business where everything relies on a smooth and efficient supply chain. A key player in this process is your supplier, and knowing how well they perform is crucial. Supplier performance metrics are like the report cards for your suppliers, showing you how they’re doing in areas like delivery times, product quality, costs, and responsiveness. These metrics help you understand whether your suppliers are meeting your needs and contributing positively to your business.

Think about the last time you received a product late or found it was of poor quality. Frustrating, right? Now, imagine the impact of such issues on your entire supply chain. When suppliers perform well, everything runs smoothly: products are delivered on time, costs are kept in check, and customers are happy. But, when suppliers underperform, it can lead to delays, increased costs, and unhappy customers. Keeping an eye on supplier performance is essential for avoiding these headaches and keeping your business running smoothly.

Great supplier performance means fewer disruptions, lower costs, and better quality, which all translate to happy customers and a stronger business. On the other hand, poor performance can cause a ripple effect of problems, hurting your bottom line and your reputation. By regularly tracking and managing supplier performance, you can build stronger relationships, reduce risks, and drive continuous improvement in your supply chain.

Why Measuring Supplier Performance Matters

Measuring supplier performance is crucial because it directly impacts the quality, cost, and reliability of your supply chain. By tracking key metrics, you can ensure that suppliers consistently deliver high-quality products, which reduces production issues and keeps customers satisfied.

Impact on Quality and Consistency

Imagine opening a delivery only to find out that the parts you ordered are either defective or not up to standard. Measuring supplier performance helps ensure that the quality of the products you receive remains consistently high. By keeping tabs on metrics like defect rates and return rates, you can quickly spot any issues and address them before they become bigger problems. Consistent quality means fewer production hiccups, happier customers, and a smoother overall operation.

Cost Efficiency

Ever feel like you’re spending more than you should be on materials and services? Tracking supplier performance can help you keep costs under control. By monitoring cost-related metrics, you can identify which suppliers are providing the best value for your money. This isn’t just about finding the cheapest options but ensuring you get the best bang for your buck without compromising on quality. Efficient suppliers help you reduce waste, avoid unexpected expenses, and improve your bottom line.

Risk Management

Supply chain disruptions can come out of nowhere and wreak havoc on your operations. Whether it’s a delay in delivery, a sudden quality drop, or a supplier going out of business, these risks can seriously impact your ability to meet customer demands. Measuring supplier performance helps you identify potential risks early on. By tracking metrics such as delivery reliability and financial stability, you can anticipate problems and take proactive steps to mitigate them. It’s like having a safety net for your supply chain.

Strengthening Supplier Relationships

Good supplier relationships are built on trust and transparency. Regularly measuring and sharing performance metrics fosters open communication and collaboration. Suppliers appreciate knowing what’s expected of them and how they’re performing. This transparency can lead to stronger partnerships, where both parties work together towards common goals. When suppliers know you’re keeping an eye on their performance, they’re more likely to stay committed to meeting your standards and improving where necessary.

Key Supplier Performance Metrics to Track

Tracking key supplier performance metrics is essential for maintaining a smooth and efficient supply chain. These metrics provide a clear picture of how well your suppliers are meeting your expectations in areas like delivery timeliness, order accuracy, lead time, product quality, cost control, communication, and flexibility. By regularly monitoring these performance indicators, you can identify strengths and weaknesses, make informed decisions, and foster stronger, more reliable supplier relationships that contribute to your overall business success.

On-Time Delivery (OTD)

On-time delivery is a crucial metric because it directly affects your production schedule and customer satisfaction. By tracking OTD, you can see how often your suppliers meet their promised delivery dates. Consistently late deliveries can disrupt your operations, leading to delays and potential lost sales. Keeping an eye on this metric helps ensure that your supply chain runs smoothly and that you can meet your own deadlines without stress.

Order Accuracy

Order accuracy measures whether you receive exactly what you ordered, in the correct quantities and specifications. Mistakes in orders can lead to production delays, increased costs, and frustrated team members. By monitoring order accuracy, you can identify which suppliers are reliable and which ones need improvement. This ensures that you always have the right materials at the right time, keeping your production line moving without hiccups.

Lead Time

Lead time is the period between placing an order and receiving it. This metric is essential for planning and inventory management. Shorter lead times mean you can be more responsive to market demands and reduce the amount of inventory you need to hold. By tracking lead times, you can choose suppliers who can deliver quickly and reliably, helping you stay agile and efficient.

Quality of Goods

The quality of goods metric looks at the rate of defects or non-conformities in the products supplied. High-quality materials are vital for maintaining your own product standards and keeping customers happy. By keeping tabs on the quality of goods, you can quickly identify and address issues, ensuring that your final products are up to par. This metric helps you avoid costly recalls or rework and maintains your reputation for quality.

Cost Performance

Cost performance tracks how well suppliers adhere to agreed-upon prices and manage costs. It’s not just about finding the cheapest supplier but ensuring you get good value for your money. By monitoring cost performance, you can identify any unexpected price increases or hidden costs and take action to control them. This metric helps you maintain a healthy profit margin and makes budgeting easier.

Communication and Responsiveness

Good communication is key to a smooth supplier relationship. This metric evaluates how quickly and effectively suppliers respond to your inquiries, issues, or changes in orders. Responsive suppliers can adapt to your needs and resolve problems faster, reducing downtime and keeping your operations on track. Tracking this metric ensures that you work with suppliers who are reliable and easy to communicate with.

Flexibility and Adaptability

Flexibility and adaptability measure a supplier’s ability to handle changes, whether it’s a sudden increase in order volume or a need to adjust specifications. Suppliers who can quickly adapt to changes are valuable partners, especially in a dynamic market. By evaluating this metric, you can ensure that your suppliers can meet your needs even when things don’t go as planned. This helps you stay competitive and responsive to market changes.

Strategies to Improve Supplier Performance

Improving supplier performance isn’t just about pointing out flaws; it’s about fostering a collaborative environment where both parties work together towards common goals. By implementing effective strategies, businesses can enhance supplier relationships, streamline operations, and drive continuous improvement. From setting clear expectations and offering incentives to fostering open communication and investing in supplier development, these strategies not only address current challenges but also lay the groundwork for long-term success and mutual growth.

Setting Clear Expectations and KPIs

The first step to improving supplier performance is setting clear expectations and key performance indicators (KPIs). Make sure your suppliers know exactly what you need from them in terms of quality, delivery times, costs, and communication. Having well-defined KPIs gives suppliers concrete goals to aim for and provides you with a benchmark to measure their performance. This clarity helps avoid misunderstandings and ensures everyone is on the same page.

Regular Feedback and Communication

Open and regular communication is key to building strong supplier relationships. Keep the lines of communication open by providing regular feedback on their performance. Let them know what they’re doing well and where there’s room for improvement. Regular check-ins and performance reviews can help address issues early on and reinforce positive behaviors. Being approachable and responsive yourself encourages suppliers to communicate openly, leading to a more collaborative relationship.

Collaborative Improvement Plans

When issues arise, work with your suppliers to develop collaborative improvement plans. Instead of pointing fingers, approach problems as opportunities to improve together. Discuss the issues, brainstorm solutions, and set actionable steps to address them. This collaborative approach not only resolves problems more effectively but also builds trust and a sense of partnership. Suppliers are more likely to be motivated to improve when they feel supported and involved in the process.

Incentives and Penalties

Incentives can be a great way to motivate suppliers to meet and exceed performance expectations. Consider offering rewards for high performance, such as bonuses, longer contracts, or increased business. On the flip side, having penalties for consistent underperformance can also drive improvement. Make sure these incentives and penalties are clearly defined in your agreements so that suppliers know the stakes and are motivated to deliver their best.

Investing in Supplier Development

Sometimes, improving supplier performance requires an investment in their development. Offer training, resources, or even technology support to help them meet your standards. This could involve providing access to better tools, sharing best practices, or conducting joint training sessions. By investing in your suppliers’ growth, you not only improve their performance but also strengthen your long-term partnership.

Monitoring and Continuous Improvement

Improving supplier performance is an ongoing process. Regularly monitor performance metrics to track progress and identify new areas for improvement. Encourage a culture of continuous improvement by setting new goals as old ones are met. Celebrate successes and learn from setbacks. This commitment to continuous improvement helps ensure that your suppliers remain reliable, efficient, and aligned with your business goals over the long term.

Conclusion

Effective supplier performance management is a cornerstone of a resilient and efficient supply chain. By consistently monitoring key metrics like on-time delivery, product quality, and communication responsiveness, businesses can identify areas for improvement and foster stronger partnerships with their suppliers. Implementing strategies such as setting clear expectations, providing regular feedback, and investing in supplier development not only improves immediate performance but also cultivates a culture of collaboration and continuous improvement.

As businesses navigate challenges and opportunities in the marketplace, prioritizing supplier performance ensures reliability, reduces risks, and enhances overall operational efficiency. By leveraging these strategies, companies not only strengthen their supply chains but also position themselves for sustainable growth and success in an increasingly competitive environment. With proactive management and a commitment to excellence, businesses can forge resilient supplier relationships that drive mutual value and innovation.

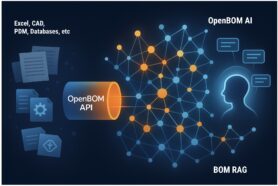

Interested in OpenBOM? Reach out.

By: Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.