Most engineering teams keep all of their data in multiple folders on their computer. As a product grows and changes, that data can become difficult to manage. Earlier today, I had an interesting conversation with one of our prospects. The discussion was about how to move from data chaos to an organized product lifecycle management system.

The person’s background is in the defense industry and he is very well aware of the benefits of large PLM systems. Coming to a small growing startup, he is now responsible for cleaning the data chaos and organizing the process. He was telling me that he would like to clean the data, bring it to order, and once everything is organized, bring a PLM system to load all the data. He is right and wrong at the same time, which caused a very interesting discussion between us.

How PLM Role is Switching From Hostile To Enabling

I agreed completely with the engineer I was talking to – cleaning and organizing data are absolutely necessary in order to switch from data management chaos to an intelligent product lifecycle management system. However, there is a difference. A typical enterprise PLM system is considered by every company as the enemy. The behavior of most legacy systems is very hostile. It is focusing on how to lock the data and make access to the data difficult. This means engineers don’t like them because people don’t like them (especially in engineering). They (PLM) slow them down and don’t allow them to run fast to get results.

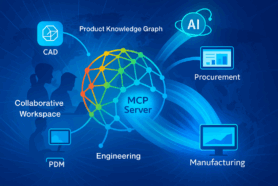

At OpenBOM, we work differently. OpenBOM’s flexible data model and integration tools are becoming the enabler of cleaning and organizing data seamlessly in an agile process. Which is a big deal. Instead of working hard on cleaning all data, bringing them from multiple formats to a single CAD system, and ensuring all data is in place (files, docs, attachments, etc), OpenBOM gives you tools to help transform the data.

This is where OpenBOM can help. OpenBOM gives you a tool to get the job done instead of waiting before the data is cleaned. Here are 3 scenarios where OpenBOM can help.

(1) Organizing Files

Let’s start with CAD and other files. Typically all files are spread around in multiple workstations, computers, and disc drives. Instead of collecting it in a single place, checking paths, and then migrating to another location, OpenBOM gives you Drive, which is seamlessly shared between multiple users and allows you to copy/paste data from multiple locations (Drive is shared). So, collecting all information becomes a very simple process. – (1) create a Drive account; (2) set all folders and share it with all users; (3) simply copy data from any place to shared OpenBOM Drive folders and you immediately start using OpenBOM Drive capabilities.

(2) Cleaning Part Numbers and CAD Attributes

CAD data is typically very messy in organizations that don’t follow the process of creating and filling in all attributes. Lack of organizational standards leads to the need to set up Part Numbers and fix all metadata (descriptions, etc.), and ensure that all properties exist in all CAD data files. Editing data is hard in CAD. You need to open every file to check it and update manually each description. Not with OpenBOM! It gives you a way to generate and manage part numbers, create items/BOMs/catalogs, suck all data to OpenBOM, update data using a familiar spreadsheet-like user experience, and pull the data back to CAD, but updated!!!

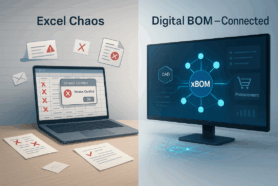

(3) Validating and organizing the initial BOM structure

Capturing BOM data from engineering sources (eg. CAD files) is hard. And it is mainly because many of these CAD files were made before organized processes kicked off. There is a need to make these Part Numbers and attributes in order. Add some of the missing attributes, and change values to some others.

Here is what OpenBOM does – it allows you to generate BOM with a “one-click” BOM function and validate BOMs for mistakes and wrong structure. The process is iterative and easy -it allows editing data in an Excel-like format in OpenBOM and then pushing it back.

Conclusion:

OpenBOM turns the process of PLM implementations upside down by introducing tools and methods to clean and organize the data in an agile and seamless way. Instead of spending time preparing the information, bringing files to a single location, validating file structure, all CAD file attributes, and validating BOM data, OpenBOM gives you tools that help to start organizing and learning data as you go. This is a big difference in the approach – from holding the data hostage, OpenBOM provides you with a mechanism to collect all information and bring them to the right place, and validate the content and correctness of the data.

REGISTER FOR FREE to check how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.