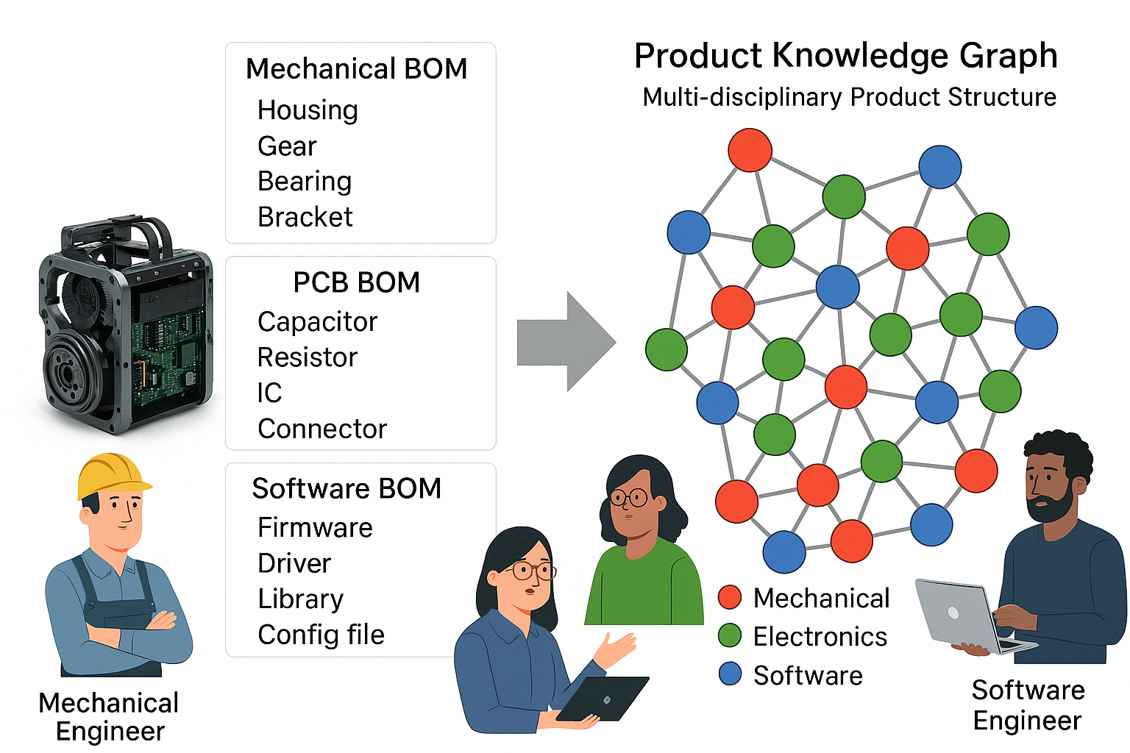

Modern manufacturing is built on data—but not just any data. High-quality, connected, and timely data is essential to move fast, avoid costly mistakes, and stay competitive. As products become more complex—integrating mechanical components, electronics, embedded software, and more—the need to bring all design disciplines into a single, accurate engineering BOM has never been greater.

Here is a story I’ve heard from our customer building complex electromechanical equipment and dealing with the complexity of ordering and multi-disciplinary BOM structures. Their team designs in both SOLIDWORKS (for mechanical) and Altium (for PCB). On the surface, everything looked fine—until they tried to unify the BOMs.

A simple component, used across both systems, became a source of misalignment. In SOLIDWORKS, the component was treated as one part (SLDPRT) in the assembly. In Altium, that same switch appeared as separate components because of different electronic parameters. When the BOMs were exported and compared, they didn’t match. Procurement got confused, everything slowed down until it was resolved. Engineering lost time in conversations. Manufacturing waited, and the project was delayed.

This is just one example of the data complexity that modern companies face daily. And it’s exactly the type of challenge OpenBOM is designed to solve—by automating and governing the flow of data from design to engineering BOMs across multiple disciplines.

The 3 Keys to OpenBOM’s CAD-to-BOM Automation

1. Flexible Data Model That Fits Your Product

Every company is different. Every product has its own complexity. OpenBOM’s flexible, schema-less data model is built to accommodate any structure, attribute, or metadata from your CAD systems. Whether you’re designing electronics, machinery, or consumer products, OpenBOM can model your product structure without forcing you into rigid templates.

This flexibility is key when translating design intent into an accurate BOM. You define what matters, and OpenBOM adapts—automatically mapping data from your CAD to your BOM.

2. Out-of-the-Box CAD Add-ins That Just Work

OpenBOM comes with a complete set of purpose-built add-ins for all major CAD systems—Solidworks, Autodesk Fusion, Onshape, Altium, and more. These integrations are not just file exporters—they are intelligent connectors that capture the exact information you need: part numbers, properties, configurations, references, and structure.

This means you can generate a complete and structured Engineering BOM with just a few clicks, right from within your CAD environment—no manual re-entry or copy-paste required.

3. Team Governance That Scales Across the Company

Consistency is crucial when multiple engineers work on the same product or across multiple projects. OpenBOM includes a robust governance model with Team Settings that let you define company-wide standards for BOM creation, item properties, part number rules, and more.

This ensures that every BOM created—whether in the US, Germany, or anywhere else—follows the same structure, naming conventions, and data logic. It’s like having your own internal playbook, enforced by the system, without slowing down the team.

OpenBOM Governance Model: Team Settings for Seamless Engineering BOM Creation

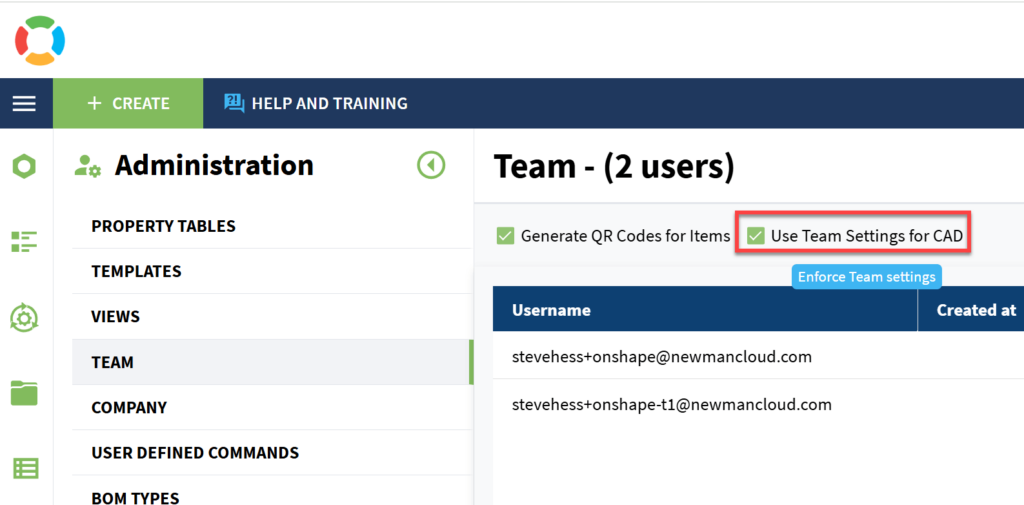

A critical element of OpenBOM’s governance is the ability to create consistent, company-wide Engineering BOMs using CAD Add-in Team Settings.

As companies grow, so do the risks of inconsistent configurations, especially when using CAD integrations across multiple team members. To solve this, OpenBOM gives administrators full control over CAD integration settings via a centralized Team Settings feature.

Here’s how it works:

1. Enable Team Settings

The OpenBOM Team Administrator activates Team Settings in the Admin Dashboard.

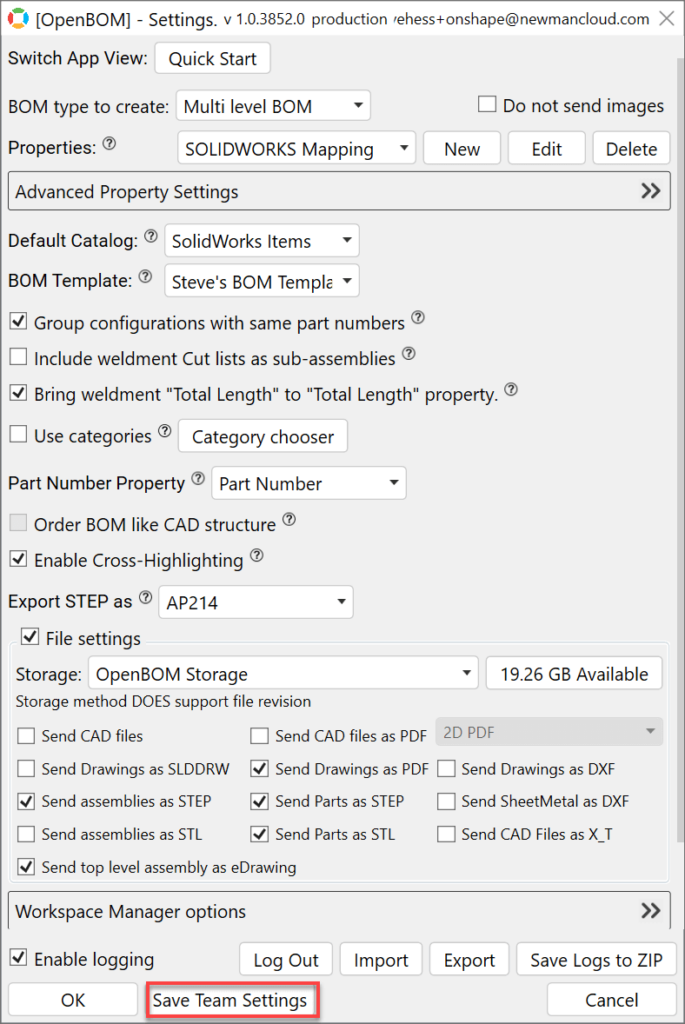

2. Set Your Business Rules. While signed in to the CAD system as an admin, configure the integration settings—select which properties to include, how to name parts, control reference structure, and more.

3. Save as Team Admin.. Save these settings and push them as the default configuration for your team. No more emailing XML files or manually aligning settings.

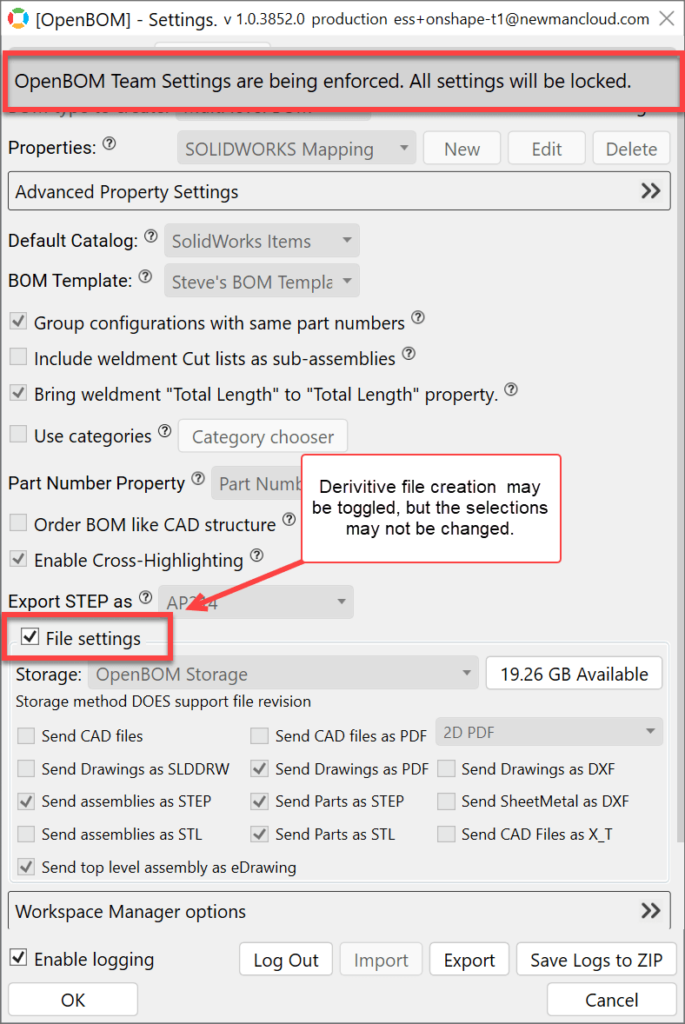

- User Experience. When team members log in, their CAD add-ins will automatically apply the company-approved settings. They can focus on design while OpenBOM ensures structure, consistency, and data accuracy.

✅ Pro tip: Non-admin users can still toggle derivative file creation on/off, making it easy to work quickly during design and enable full exports when ready to push BOMs into OpenBOM.

🎥 Watch the video about how it works – OpenBOM Team Settings Demo.

Conclusion: BOM Complexity Is Real – OpenBOM Solves It

Engineering BOMs are the backbone of your product lifecycle. With OpenBOM, you can finally automate the transition from CAD to structured BOM, reduce errors, and lay the foundation for accurate purchasing, manufacturing, and supply chain collaboration.

If you’re tired of spreadsheet chaos or legacy PDM tools that don’t speak your CAD language, it’s time to see how OpenBOM can streamline your BOM process from day one.

👉 Book a live demo and REGISTER FOR FREE and experience BOM automation done right.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.