New product development (NPD) can be a complex and time-consuming process. From ideation to prototyping and design to production, there are many steps involved in bringing a new product to market.

Why Engineers Need More Speed?

These days everyone wants to accelerate their activities. The speed of the business is growing. We need to have a faster response and react faster to problems and challenges. And one of the outcomes in the industrial and manufacturing world is the need to develop faster. An old product’s lifecycle is too slow and companies are looking at how to move their processes faster. Here are a few reasons why it can be beneficial:

- The faster a product can be developed, the sooner it can be brought to market, giving a company a competitive advantage over its rivals.

- Speed can help reduce costs by minimizing the time and resources required to develop a product.

- Speed can also help companies respond more quickly to changes in the marketplace, customer needs, or technological advancements.

By accelerating the development process, engineers and designers can identify and correct issues more quickly, leading to a higher-quality end product. Ultimately, speed is crucial in new product development and engineering activity because it can make the difference between success and failure in today’s fast-paced business environment.

How To Streamline New Product Development

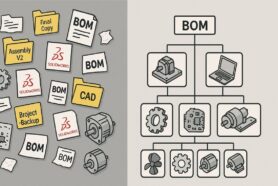

Existing PLM and ERP systems are too slow to accommodate the needs of organizations to bring new products fast to the market. Those systems are well structured, but you just cannot move fast enough. Therefore we found many engineering teams of different organizations are struggling to use them.

New product development requires a reimagining of the traditional approach, to bring collaboration, data intelligence, and fast communication between teams or engineers, manufacturing planners, and procurement to work together, to build prototypes to deliver results fast.

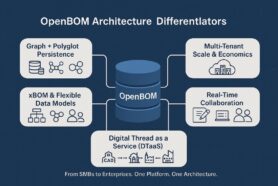

At OpenBOM, we work on developing new methods and collaboration technologies to help multi-disciplinary distributed teams to accelerate new product development and to help them to make faster and better decisions.

CoLab and OpenBOM Tech Talk

I’m super excited to introduce a Tech Talk webinar together with Adam Keating, CEO of CoLab where both of us will share our experience of helping product development teams to streamline engineering and manufacturing processes. In particular, we will talk about simplifying the handoff from design to production for stage Gate NPD.

This event is perfect for those who are interested in optimizing their new product development process. Whether you’re a product designer, engineer, or project manager, this event is an excellent opportunity to learn from experts in the field and gain valuable insights into the latest trends and best practices.

Conclusion:

Data handoff between Engineering and Manufacturing functions is one of the most complex issues that exist in product development and manufacturing. It is important from both design and production standpoints. It requires consolidated data management, event orchestration, intelligence, and collaboration between different departments and groups of people.

JOIN THE EVENT on April 27th and learn more about the topic with me and Adam.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.