As we open 2025, it is time to ask some fundamental questions about the technologies and architecture of PLM software (check my separate article about PLM 2025 trends) . I wrote this article for PLM and technological architects who asked me questions about how modern PLM software architecture is different. Is there a real difference or is it marketing selling old systems with new tags in new envelops?

In the next few articles, I want to give you some perspective on the selection of the right information technologies and why not all systems were born and developed the same. More companies speak now about product data and the importance of information over the tools. In a world where we are gradually coming to AI as a universal data hammer, it is very important to understand what tools and technologies we will be using to collect, organize, and manage product information and change control.

While Product Lifecycle Management (PLM) software has been a cornerstone of manufacturing and product development for decades as a “single source of truth” to provide up-to-date information to everyone in the company, the data management architecture and tech matters when it starts impacting what we do in an organization with business systems. And PLM is one of them.

As we move deeper into the digital age, the limitations of traditional PLM software have become increasingly apparent. These legacy systems, while once revolutionary, now struggle to meet the demands of modern needs and digital transformation initiatives.

Architectural Limitations

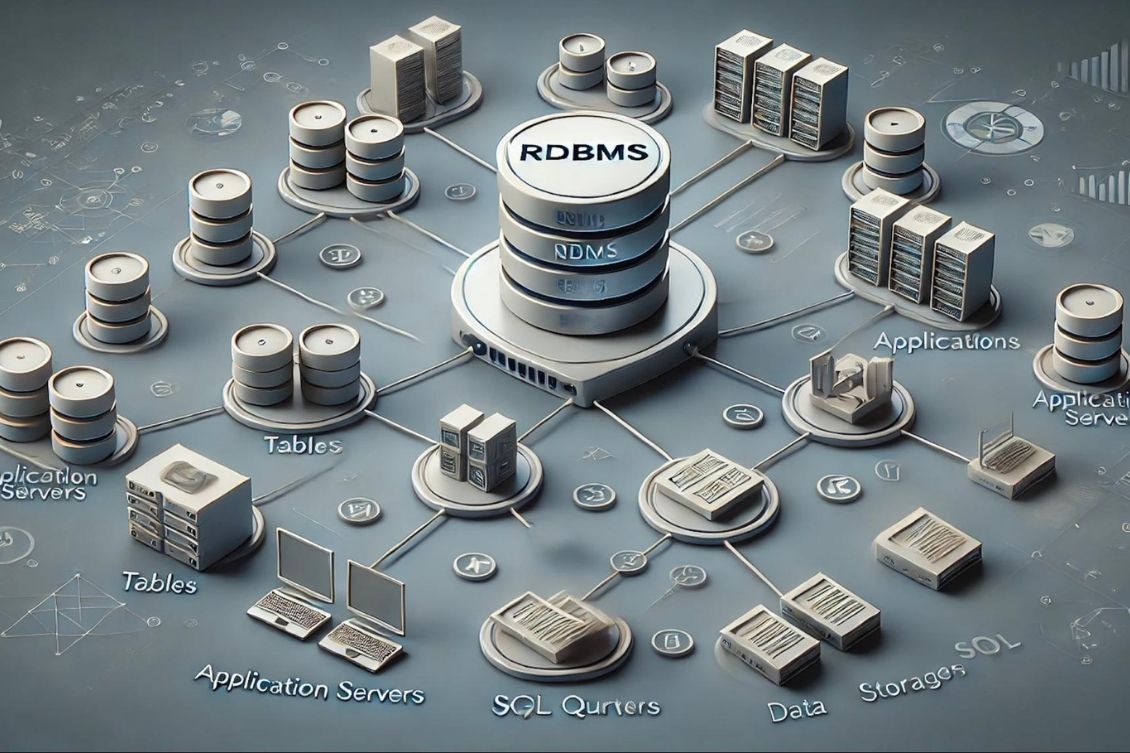

At their core, traditional PLM systems are built on architectural decisions made more than two decades ago. The foundation rests on tenant architecture and relational database management systems (RDBMS) that were designed for computing circa 2000. This architectural approach, while stable and proven, creates significant limitations in today’s interconnected business environment.

The tight coupling between application logic and databases represents a particularly challenging constraint. This interconnection makes it difficult to evolve the system, implement new features, or adapt to changing business needs without significant restructuring. The reliance on SQL tables and local database IDs further compounds these limitations, creating rigid structures that resist modern flexibility requirements.

Data Isolation and Sharing Constraints

One of the most significant drawbacks of traditional PLM systems is their inability to scale beyond single-company implementations. These systems were designed with a company-centric mindset, lacking robust data-sharing capabilities that are crucial in today’s collaborative business environment. This limitation becomes particularly problematic as:

- Supply chains become increasingly integrated

- Cross-company collaboration becomes the norm

- Global product development teams need real-time access to shared data

- Industry ecosystems require seamless data exchange

While all these requirements seem to be obvious, none of them can be implemented using traditional PDM/PLM architecture without special “hacks”. There is no good way to support a model collaborative environment for PLM solutions and after all, the data is dumped into Excel to be transferred elsewhere.

It Was Born to Manage CAD Files

Traditional PLM systems were primarily developed around CAD file management and product data management architecture including traditional change control processes (aka traditional check-out/check-in processes). While these remain important functions, modern product development requires a much broader scope of capabilities. The narrow focus manifests in several ways:

The systems excel at managing engineering content (primary mechanical CAD files), but struggle with the following topics:

- Integration of multi-disciplinary data sources (electronics and software)

- Seamless collaboration with multiple teams working granularly with the same data records

- Limitations of change management requires record locking and changes

Data Relationship and Analytics Challenges

The relational data models that underpin traditional PLM systems create significant challenges for modern data usage scenarios. These challenges include:

Complex Data Relationships

Finding and managing relationships between different systems and data types is unnecessarily complicated. The rigid structure of relational databases makes it difficult to discover and leverage connections between different data elements, limiting the potential for insight and innovation.

Limited Analytics Capabilities

The traditional architecture severely constrains the system’s ability to provide advanced analytics and intelligence. Modern requirements for machine learning, predictive analytics, and real-time decision support are difficult or impossible to implement effectively within these legacy frameworks.

Data Recombination Difficulties

The relational model makes it challenging to recombine data in new and useful ways. This limitation becomes particularly problematic when trying to:

- Create new views of existing data

- Combine data from multiple sources

- Generate insights across different data domains

- Support new business processes or analysis methods

Conclusion and Looking Forward

As organizations continue their digital transformation journeys and looking to support connected product development processes, the limitations of traditional PLM systems become more pronounced. Modern enterprises require solutions that can:

- Support flexible, cloud-native architectures with flexible data models

- Enable seamless collaboration across organizational boundaries

- Provide advanced analytics and intelligent query capabilities

- Handle diverse data types and sources effectively

The future of PLM lies in supporting an entire product lifecycle and provide systems that can overcome these traditional limitations while maintaining the robust product lifecycle management capabilities that made these systems essential in the first place.

Traditional systems with centralized data management will stay as we know them. But as companies looking for solutions to manage product related data and making data easy accessible for business the limitation of traditional PLM with “document management” functions at its core will be more and more limited.

This will likely require fundamental rethinking of PLM architecture and capabilities, embracing modern technologies and approaches while preserving the core value of comprehensive product lifecycle management.

Stay tuned for the next articles where I will share specific examples of how OpenBOM system architecture is different and what it allows to do for companies.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.