If you are manufacturing a product with an electronic component, you most likely have heard of the chip shortage. Your prices are going up and the supply is thinning. If you are a consumer, you will start to see prices increase for everything from laptops to electric toothbrushes and everything in between.

The Wall Street Journal found that HP has raised consumer PC prices by 8% and printers by 20% in just the last year. The article goes on to say that Digi-Key “has raised prices of semiconductor-related components by roughly 15% this year.”

We all know there are several reasons for these spikes. The demand for medical devices increased due to the pandemic. The pandemic also made for more remote work which meant more computers being purchased for home office use. As schools were shut down, you also had to get a computer for your child. As you were remote, you might have even had to purchase a new webcam for video calls. And maybe you splurged to get a PlayStation 5 to curb your boredom.

While most believe this will last another calendar year, Forrester believes the shortage can extend into 2023. As a product-based company, you can’t wait for this to blow over. You need to manage your risk and prepare your supply chain accordingly.

So what can you do? The bad news, there is no magic button to have this all disappear. The good news, there are existing tools to help manage risk.

What To Do About Shortage?

Like I said, there is no magic button to have this disappear. But there are some things you can do. Here is what I recommend. Ironically, I have always recommended this but during this time it’s become even more important.

Managing Costs

This one is obvious, you always need to manage costs. But when you have cost inflation and shortages, it becomes even more important. The first step is to understand your current costs and see where they are increasing. Even if you have a strictly mechanical part, your costs will be increasing. Prices for metal, plastics, and even paper have seen increases in the past year.

Also, understand your margins. Again obvious but with part inflation, you still need to turn a profit so you can stay afloat during these difficult times. Calculate not just your COGS but your landed costs. You probably know that shipping from China has increased dramatically as well. With cost inflation and shipping costs, can you absorb these increased prices and sell your product to turn a profit?

So, how do you manage your costs? First, you need to collect and analyze your data. You should already have a part database that stores all of your part data, including prices. If you have not, I suggest you learn how to.

Having this database will make costs transparent for current and alternative components from different suppliers. Having this laid out transparently will provide you with the data to make a quick decision, which leads us to my next point.

Make Quick Decisions

I was speaking with a client today and he mentioned that a supplier provided him a quote for 1,000 units of a chip. He only wanted 500 but the supplier set the MOQ at 1,000. He discussed this with his purchasing manager and after a few days decided to purchase 1,000 units. They called the supplier and found out the deal was dead. They didn’t have inventory for them… Bad news.

On the other side, we have a client that in anticipation of this purchased 5k+ chips. It will not be enough to get them through 2023, but it has helped them.

The solution is clear, if you have an opportunity to purchase extra stock, it’s wise to do so. Just make sure finance gives you the green light for the cash flow.

How do you make these quick decisions though in such an inflated market? The best thing I can tell you is to collect data. Similar to managing costs, you need a part database to manage these items so you can make informed decisions quickly.

The client who purchased 5k chips made this decision quickly to reduce his risk. He did this by managing the prices and lead times from other suppliers in his part database.

Manage Inventory

Managing inventories has become difficult for several reasons. First, you have part inflation and you might want to try to see if you can hold off purchasing which is highly unlikely unless you have stock to hold you over for the next 18 months… Secondly, shipping prices have increased and shipping out of Southern China right now has become very difficult. We also had products sitting in 40’ containers for weeks because of a COVID breakout at YanTian port.

But life does not stop. You must analyze the supply chain shortage with the demand from your customers. This means starting the procurement process for the black Friday rush earlier rather than later. Have tolerances for production delays due to part shortages and shipping delays due to port congestion.

And again, how do we manage inventories and plan production during this time? Like my two other suggestions, collect data and plan accordingly. You can only make decisions based on the supporting data.

While you might have never planned for anything like this before, understand the lead times for not just your current parts but also the alternative parts and alternative materials and processes. Have a part database that lists out the lead time and other purchasing information.

If you have a product that is being affected by the part shortage please feel free to reach out to us. We would love to hear your story.

How OpenBOM Can Help

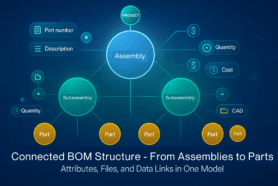

Managing cost, inventory and having a tool to help you to make a quick decision is obvious, but it is easier to say than to make it happen. While large enterprise companies are equipped with enterprise software and procurement departments, hundreds of thousands manufacturing companies are still managing product data using old PDM tools and using Excel spreadsheets to manage, cost and procurement. At OpenBOM we can see these companies every day.

OpenBOM provides you a SaaS tool, which is instant to start with, has seamless integration with your engineering tools and provides instant global collaboration capabilities to your team as well as contractors and suppliers. OpenBOM gives you a foundation to manage your product information, including lead time and prices, in a centralized database that is used to make informed decisions. We provide you with the capabilities to seamlessly manage your parts, vendors, bill of materials, purchase orders, and change orders. All BOM, engineering, and manufacturing information are stored in the cloud which you can share with anyone.

Register for FREE to create your OpenBOM account and reach out to us via support @ openbom dot com if you have any questions.

Regards,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.