In the fast-evolving landscape of the manufacturing industry, a large transformation is underway—one powered by digital innovation. As companies race to stay competitive, the adoption of digital technologies has become not just a choice but a necessity. This digital revolution, known as digital transformation, is reshaping every facet of manufacturing, from the shop floor to the boardroom.

In this era, the impact of digital transformation goes beyond mere technological upgrades. It represents a fundamental shift in how manufacturing companies operate, collaborate, and build partnerships. For those involved in building products, especially in the realm of contract manufacturing, the effects are profound.

This blog focuses on how relationships change when manufacturers digitalize their processes with their contract manufacturers or suppliers. We’ll go over how embracing digital tools and strategies can lead to enhanced communication, streamlined processes, and ultimately, stronger alliances.

Understanding Digital Transformation in Manufacturing

In the realm of manufacturing, the term “digital transformation” is more than just a buzzword—it’s a shift in the way businesses operate and deliver value. Digital transformation encompasses a number of technologies and strategies aimed at leveraging the power of digital tools to enhance efficiency, visibility, and overall business performance.

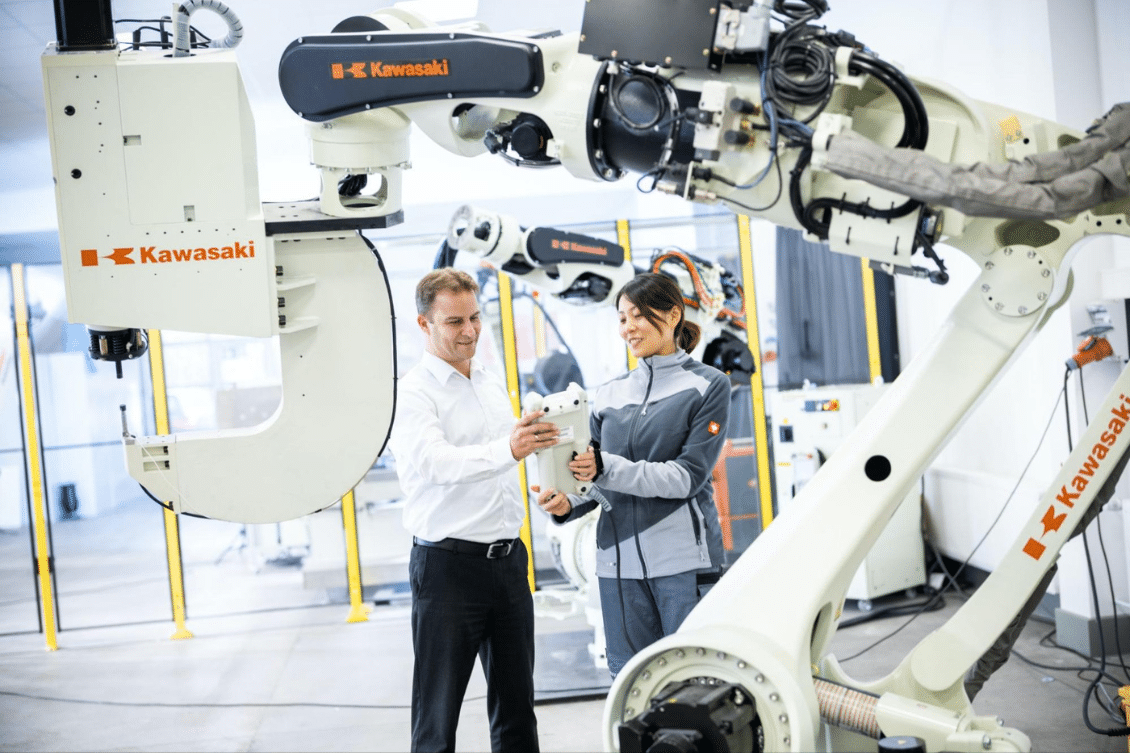

Digital transformation involves the integration of digital technologies across all aspects of a manufacturing business. This includes processes, operations, supply chain management, and communication channels. The goal is to not only keep pace with technological advancements but to proactively use them to gain a competitive edge. Here are some examples:

- IoT (Internet of Things)

- Automation

- Data Analytics

- Cloud Computing

- Artificial Intelligence (AI)

The Impact on Communication and Collaboration

In manufacturing, precision and timing are key, while effective communication and collaboration form the infrastructure of success. Digital transformation introduces a new era where information flows seamlessly, connecting manufacturers and contract partners in ways previously unimaginable.

Digital transformation brings an improvement in communication, that goes beyond traditional boundaries. Manufacturers and their suppliers can now communicate in real-time, breaking down silos and creating an agile environment. Whether it’s conveying design changes, production updates, or addressing unforeseen challenges, the adoption of digital communication enhances collaboration.

Real-time Data Sharing

Central to this transformation is the ability to share data in real-time. Information regarding production schedules, inventory levels, and quality control metrics is instantly accessible. This not only reduces delays but also allows for quick decision-making, enabling manufacturers and contract partners to stay on the same page and adapt to changing circumstances swiftly.

Collaboration is elevated to new heights through digital platforms specifically designed to facilitate joint efforts. Cloud-based solutions enable manufacturers and contract manufacturers to collaborate on a shared digital workspace. Whether it’s co-designing products, optimizing production processes, or jointly analyzing data, these platforms foster a sense of partnership that goes beyond geographical distances.

Data-Driven Decision-Making

In the world of manufacturing’s digital makeover, data becomes king, guiding businesses to make smarter choices. Digital transformation isn’t just about fancy technologies; it’s about using information wisely to improve decision-making.

One of the main goals is to use real-time data to make our operations smarter. Monitoring production, checking inventory, and ensuring quality—all in real-time—helps us make quick decisions to keep things running smoothly.

Big decisions need solid info. That’s where data comes in at a strategic level. We look at what’s happening in the market, what customers like, and where the industry is headed. It’s like having a roadmap for success that adapts as the road twists and turns.

Enhancing Supply Chain Visibility

Digital transformation brings transparency to the supply chain by offering real-time insights. Manufacturers can track the movement of raw materials, work-in-progress, and finished goods at every stage. This real-time visibility allows for better decision-making and the ability to address issues promptly.

With increased visibility, manufacturers can anticipate and manage disruptions more effectively. Whether it’s a delay in the shipment of raw materials or unexpected changes in demand, having a clear view of the supply chain enables proactive measures to keep operations running smoothly.

This allows you to be more proactive in your approach. Instead of reacting to problems as they occur, enhanced visibility allows manufacturers to be proactive. They can foresee potential issues, plan for contingencies, and ensure that the supply chain remains resilient in the face of challenges.

By enhancing visibility, manufacturers build stronger relationships with suppliers. Timely information about inventory levels and production schedules allows for better coordination. This not only improves efficiency but also nurtures long-term partnerships built on trust and collaboration.

Conclusion

Moving towards digital processes will not just improve your overall output but it also improves the relationship between you and your supplier. From enhanced communication and collaboration to data-driven decision-making, supply chain visibility, and more, each aspect leads to a more dynamic relationship with your manufacturing partner.

OpenBOM is a cloud-based PDM & PLM platform to manage your engineering and manufacturing data. Companies from startups to Fortune 500’s use OpenBOM to create a centralized database to bring in, store, and manage their manufacturing data. With this infrastructure, users also use OpenBOM to streamline both their change management and PO processes.

If you need to improve the way you manage your data and processes, share data instantly, or collaborate with contractors and suppliers, contact us today for a free consultation.

Regards,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.