In a world where customization and uniqueness are highly valued, the demand for custom parts has soared. Whether it’s for mass production or prototypes, manufacturers turn to suppliers to make those designs become a physical part. However, during the procurement process, there are always multiple challenges that affect your end product and usually end with higher prices and a longer-than-expected lead time.

From the initial prototype to the final product, the journey of procuring custom parts is filled with complexities. In this blog, we will cover the common hurdles faced by customers seeking custom parts and how these obstacles can impact their projects, timelines, and overall satisfaction.

Why are Custom Parts More Complex?

There are reasons why engineers and product developers design a complex part instead of using an off-the-shelf part. They are tasked with designing a new product and the parts in the market don’t fit the requirements for their product. Therefore, engineers are forced to design something new. While this is great, it does add complexities when you create prototypes and move to mass production.

The main reasons why these are more difficult to procure are the following:

- Engineering complexity

- Limited Supplier Options

- Longer Lead Times

- Higher Costs

- Quality Assurance and Testing

Pains of Procuring Complex Parts

There are clear complexities when it comes to engineering custom parts. But how about on the procurement side? Is it similar to purchasing an off-the-shelf part?

Not really, there are additional complexities as well in purchasing custom parts. These issues can stem from procurement not having a technical understanding of the part, all the way through to having the proper visibility in the supply chain.

Here are the most common pain points that manufacturers encounter when purchasing custom parts.

Clear Communication

A custom part is more complex than purchasing an off-the-shelf part and it starts with engineering conveying the requirements of the product to the business.

This is usually where communication becomes a problem. The part and all of the part requirements, such as material, finish, tolerances, and more need to be shared with the procurement team or the individual who will be responsible to purchase the parts.

Also, parts are constantly changing. It’s not just good enough to pass the product data to procurement once and be done with it. For each change, the product data along with all of the requirements need to be re-sent to your procurement team.

Clear communication also takes time to establish. The Fast Radius found that during the quoting process, the number one pain point was that “communicating with manufacturers (suppliers) takes up too much of my time”

Miscalculated Lead Times

If you are engineering a custom part it usually means that no one has ever fabricated it before. You should always try to find a supplier with experience but sometimes you can’t plan for certain issues that occur during fabrication.

Oftentimes, suppliers will think the part is straightforward. While sometimes this is true, other times they are wrong and did not anticipate certain issues to occur during fabrication. This leads to an increased lead time and costs.

In addition, oftentimes, a custom part has multiple processes involved. These processes include purchasing raw materials, primary fabrication steps, such as CNC, 3D printing, laser cutting, stamping, etc, and secondary processes. These secondary processes are usually done by sub-tier suppliers.

Aligning the raw material, primary fabrication processes and secondary processes to come together is difficult. There is a need for clear communication between the manufacturer and the suppliers in addition to a common understanding of the steps each supplier needs to perform.

For off-the-shelf parts, you just go to McMaster Carr, Digikey, or other distributors and purchase the part based on the manufacturing part number (MPN). With custom parts, all of the processes need to align with the lead time proposed by your contract manufacturer, prototype shop, or supplier.

High Costs

Prices for an off-the-shelf component are usually consistent. Yes, we had part inflation during COVID. But usually, you can rely on these costs. You can purchase it for a prototype and not expect the cost to increase when you purchase them in mass production.

Custom parts are a bit more difficult and the quotes you receive from suppliers during development might not be the same price you end up paying during production. A supplier often gives a nice low price to get you interested in working with them. However, after prototypes are made, the quotes go up. There are several reasons for this. Sometimes, it’s because the supplier didn’t fully understand the requirements of the part while other times, it was planned to get you trapped with them.

The same Fast Raius article, also quoted that many quotes from suppliers for custom manufacturers do not reflect the project requirements and that inaccurate quotes slow down innovation.

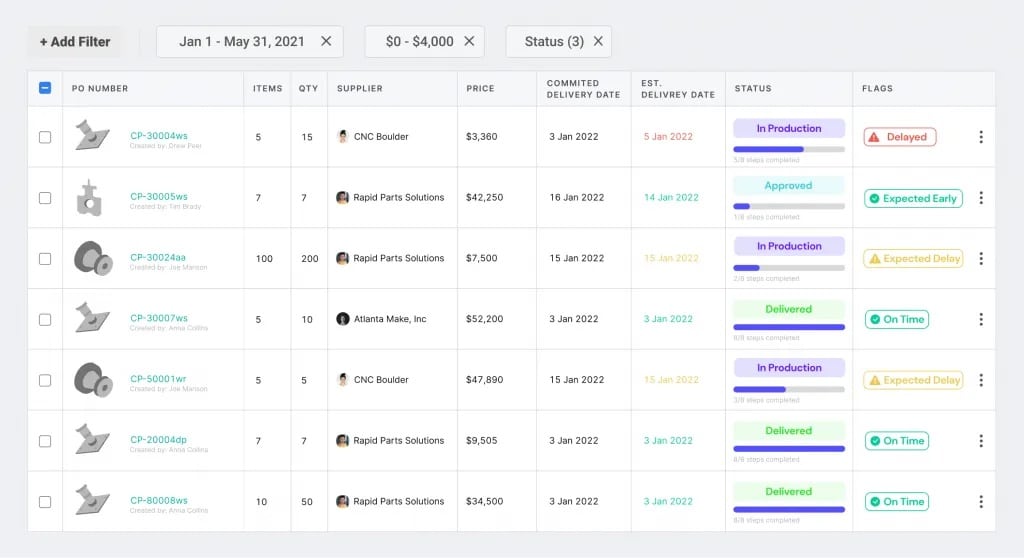

Transparency Through the Fabrication Processes

Oftentimes, after you place an order for a custom part, you have no real-time updates of where your supplier is at in the process. For example, suppliers are usually not proactive to tell if the part is being sent out for anodizing, or if they are reviewing quality, etc…

This lack of transparency makes it impossible for a manufacturer to know where that part is in the manufacturing steps and ensure whether or not they are on the correct timeline to ship.

Placing POs

While this sounds straightforward, placing POs to multiple suppliers is difficult. With placing POs, you also need to manage the payment terms of each supplier. Your payment terms with one supplier might be different with another supplier.

In addition, you need to plan when you should purchase parts so all the parts are ready for assembly at the same time. If you are using a contract assembler for assembly then they might charge you for warehousing if they hold parts for too long.

How to Solve This?

With the introduction of digital tools, manufacturers can improve their supplier visibility and improve the experience of purchasing custom parts. These digital tools help you to communicate with your supplier, convey design to your organization, offer vetted suppliers, and more.

More specifically, Jiga, helps manufacturing companies speed up the procurement of parts. They accomplish this by ensuring cost-competitive production with its tech-driven operations and access to the top 5% of global manufacturing suppliers.

What Can You Do Today?

If you are looking to improve the way you purchase custom parts then technology can bring you closer to it. However, before you digitalize your processes, you need to first understand how you manage your product data. Being premature with this will lead to a digital mess.

The goal should be to start managing your product data from the start of the process. This usually starts with engineering. If engineering is unable to create the proper data then procurement and other departments will have trouble purchasing the correct parts and other supply chain-related activities.

OpenBOM is a cloud-based PDM & PLM platform to manage your engineering and manufacturing data. Companies from startups to Fortune 500s use OpenBOM to create a centralized database to bring in, store, and manage their manufacturing data. With this infrastructure, users also use OpenBOM to streamline both their change management and PO processes.

If you need to improve the way you manage your data and processes, share data instantly, or collaborate with contractors and suppliers. contact us today for a free consultation.

Regards,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.