The introduction of agile methodologies in the world of software development has reshaped the way teams and organizations approach product creation. Agile principles emphasize flexibility, adaptability, and rapid response to change. Given the dynamism inherent in this approach, agile product development naturally demands new features in data and process management.

Agile originated in the software industry, but its principles can be and have been applied successfully across various sectors. At the heart of agile is a simple idea: break down complex projects into manageable chunks, or ‘sprints.’

Earlier in our blog, I introduced you to details about how OpenBOM Agile New Product Development can help to organize and streamline the product development process in a much faster and easier way. Integration of four key elements of the product development process – design, BOM management, purchasing, and assembly is a key to access.

A core element of this new product development process is cloud inventory management. This is not a natural element of PLM (most of PLM systems I know don’t count on inventory), which expands OpenBOM NPD capabilities in an unusual way. Let’s talk about why a proper inventory management process is key to streamlining new product development using OpenBOM.

The New Needs Introduced by Agile Product Development

Agile product development is characterized by iterative processes, quick iteration and feedback loops, and the ability to pivot based on changing requirements. With such fluidity, traditional data and process management systems are often found wanting. There’s a strong demand for processes that can seamlessly integrate various facets of product development, from conceptualization to market release. For most PLM systems, a release means to transfer data to the ERP system. But here is the thing, NPD organization is dynamic and fluid and in most cases doesn’t work well with the enterprise procurement process. OpenBOM’s innovation is to connect all these steps in a single process.

OpenBOM’s Novel Approach in New Product Development (NPD)

At OpenBOM, we are pioneering in its approach to NPD by leveraging modern agile development tools. Recognizing the complexities and multifaceted nature of product creation, OpenBOM integrates the necessary components to drive efficiency and adaptability. By leveraging cloud technology, OpenBOM offers real-time updates, collaboration, and integration, ensuring all stakeholders are on the same page.

Linking Engineering and Procurement Processes

Central to OpenBOM’s methodology is its ability to integrate engineering and procurement. In the realm of NPD, the synergy between these two domains is vital. The designs that engineers produce are only as good as the materials procured to bring them to life. OpenBOM ensures a seamless flow of information between these two critical areas, reducing lead times, eliminating communication gaps, and ensuring product quality.

The Four Elements of OpenBOM NPD

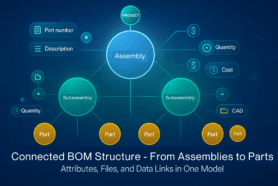

OpenBOM’s approach to NPD is underpinned by four essential components:

- Design: The genesis of any product, ensuring that designs are agile-compliant, adaptable, and aligned with market needs.

- Bill of Materials (BOM): The blueprint of product creation, detailing components, quantities, and relationships. The Digital BOM process brings everyone on the same page (oops… BOM).

- Purchasing: The acquisition of necessary materials and components for product realization.

- Assembly: The final step where designs come to life, turning concepts into tangible products.

The Importance of Inventory and Purchasing in Agile NPD

While all four elements are integral, purchasing stands out as a key element in the process. Here, cloud inventory control becomes pivotal. Real-time updates on material availability, supplier lead times, and costs are essential for an agile NPD process. Cloud inventory management systems, with their inherent connectivity and scalability, provide this data on-the-fly, enabling NPD teams to make informed decisions rapidly.

Conclusion

In today’s fast-paced product development landscape, integration is more than a buzzword—it’s a necessity. Linking the multiple steps from engineering to procurement ensures that products not only come to life but do so efficiently, meeting market demands and timelines. Inventory control, through cloud-based systems, has emerged as a key enabler to support manufacturing organizations in their key differentiators and is non-negotiable in this paradigm. To truly embrace the agility and responsiveness that today’s market demands, businesses must recognize and harness the power of integrated cloud inventory management in their NPD processes.

REGISTER FOR FREE and check how OpenBOM can help you by trying out our free 14-day trial.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.