Are you tired of your engineers using Excel instead of a Product Lifecycle Management (PLM) system when it comes to managing product data and executing engineering processes such as change requests and approvals? You’re not alone. Working for a few decades with many manufacturing companies I found the Excel paradox to be one of the most popular tools to manage data. In many companies, Excel is still used as the de facto tool for managing product information and related documentation despite all the benefits a PLM system can bring.

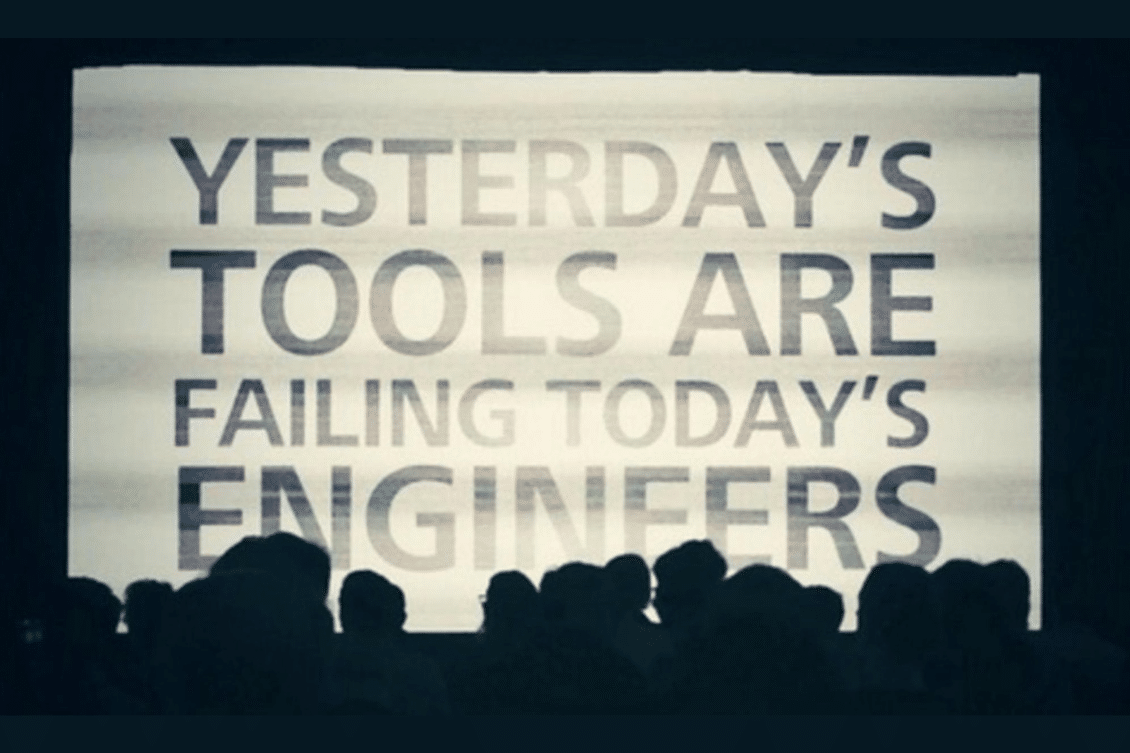

But why do engineers and everyone else in the manufacturing business continue to rely on this spreadsheet software rather than invest in new technology? Well, the answer might surprise you – but first, let’s take a closer look at some of the problems associated with using Excel in manufacturing operations…

PLM Spreadsheets – From Odes to Woes

More than a decade ago, I wrote this article, but manufacturing companies keep using Excel and causing damage. Here are 5 problems directly associated with the usage of spreadsheets:

It becomes complex over time. You always start with something simple to do. A few columns; simple formulas. But life adds additional parameters, and data to manage…. and then you can hardly manage it at all. You don’t remember all your excel dependencies. The Copy/Paste you loved, in the beginning, is no longer an easy task…

You cannot change it easily. At the beginning of your Excel story, it seems so easy to change. You can send it to any person, add information, delete, manage reports, etc. But as time goes by, nobody remembers the really good relationships you built in Excel. To touch data in Excel becomes so complex! I’ve seen many organizations that have an “Excel Manager” duty. These people are called “mission-critical Excels”.

Data is not only in Excel. Your PLM life is not in Excel only. A lot of information exists in CAD, Designs, ERP, or in additional legacy applications. In my view, Excel is a very bad integration tool. You cannot easily point to information residing in other systems. But to manage these relationships, it’s really important to have the right data in your hands when you need it.

Where is my latest Excel? I’m sure you have asked this question many times. Is it the one connected to your mail? Is it the one on your laptop, or is it the one in SharePoint? When you have multiple Excels, and especially if you have multiple versions of these Excels, you will really be lost…

The hidden cost of dependencies. At the beginning of the Excel journey, it is so easy to send an Excel file to your colleagues. You just attach it to your mail and it’s delivered. But as soon as your Excel becomes complex such as being connected to other data sources or linked to other Excels, you cannot encapsulate it so easily. So, sometimes sending it via email isn’t so trivial.

Excel: Second Best Software For Any Task?

The question I’ve been asking for years, is why despite all advantages of PLM systems and technologies, engineers and many other manufacturing professionals keep choosing to use Excel (or spreadsheets) instead of PLM tools and technologies.

A large number of OpenBOM customers are using Excel as a data management tool filling the gap of data management in the engineering nirvana of CAD design and downstream process management including change control, cost, purchasing, etc. So, why is it so popular?

Below are the top five reasons why I prefer working in Excel to manage my product data and product lifecycle:

1. Simple.

Simple means simple. The concept is clear, the tool is easy. The idea of a single big table is appealing. No need to train people, You can start straight out of the box. Later, you will realize that “simple is not as simple as you think”. But it will come later after you spreadsheet – but until you get there, you are a happy user :).

2. Flexible.

Implementation and planning of enterprise data and process management take time. PLM tools are notoriously famous for complex setups, long implementation cycles, and high costs. To plan how to manage product data and lifecycle in your organization, you need to spend time and effort. But if your tools are on a whiteboard and flexible to the level of “one size fits all”, you can start right now. The flexibility of Excel allows you to grow as you go. You don’t need to have models – just put your data and search it afterward.

3. Absorb any type of data

Very often, engineers need to introduce new pieces of information and do it quickly and easily. Spreadsheets are here to help you without much hesitation You can easily create a new workbook, or worksheet, add columns, delete columns, etc. The beauty of a spreadsheet is that it is all-inclusive J… when you think about vendor-related stuff.

4. Physical ownership

This is true. If you have XLS files or spreadsheet documents, you don’t need to be concerned with how to save, copy, and transfer your data. The feeling of ownership of your work is very important and engineers really like it.

5. Transferable.

Another element of independence from any environment. It is very easy to send a file via email or share it. Engineers can control how the files are saved and maintained. So, I can transfer them inside and outside of the organization to facilitate collaboration.

Excel Is Delayed Death Of Data

Excel is undoubtedly one of the most popular and widely used software programs in the world, with over a billion users globally. It is a versatile tool that allows users to perform various calculations, manipulate data, and create charts and graphs. However, in a modern world of data management and analysis, I’d call Excel a “delayed death of data”. Here are a few reasons why is it so.

One of the main reasons is the issue of data quality. Excel allows users to input data manually, which can lead to errors and inaccuracies. For example, if a user enters a wrong number, it can be difficult to identify and correct the mistake, which can have significant consequences. Data quality is critical in any organization, and inaccurate data can lead to poor decision-making, which can be costly in the long run.

Another reason why Excel can be considered the delayed death of data is the issue of data silos. Excel files are often created and stored locally on individual computers, which can lead to data silos. Data silos occur when data is fragmented across multiple files and systems, making it difficult to access and integrate. This can lead to duplicated efforts and inconsistencies in data, making it challenging to get a comprehensive view of the organization’s data.

Excel’s lack of scalability is another reason why it can be considered the delayed death of data. Excel is suitable for small to medium-sized data sets, but it can struggle to handle larger and more complex data sets. As the amount of data grows, Excel can become slow and cumbersome, making it difficult to work with. This can result in delays in data processing and analysis, which can impact decision-making.

Excel’s lack of security is another issue that makes it the delayed death of data. Excel files are often shared through email or other unsecured channels, which can put sensitive data at risk. Excel files are also vulnerable to viruses and malware, which can compromise data security. In today’s world, data security is critical, and any breach can have severe consequences.

Conclusion:

Spreadsheets are powerful and versatile tools that have many benefits, but it is not without their drawbacks. I use the “delayed death of data” as a term to describe how Excel’s limitations can impact data quality, data silos, scalability, and security. While spreadsheets remain a popular tool for many organizations, it is essential to consider the limitations and drawbacks of the software when working with sensitive or critical data.

Special PLM tools are much better suited for handling product data starting from Item-Instance Relationships, Management of Product Structures, Revision control, and many others. It is very important to understand the obvious gaps in Excel before deciding to commit to using it. The hidden price of using Excel is coming later and in many situations, manufacturing companies pay a lot to get rid of spreadsheets.

REGISTER FOR FREE to start a free trial and check how OpenBOM can help.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.