The common story is for manufacturers to outsource production overseas to take advantage of lower costs amongst other things. At first, their experience is usually good, maybe some hiccups but usually it’s positive and they choose a contract manufacturer or a few suppliers to build their products. While everything starts off well, it’s common for challenges to arise: shipments delayed by weeks, products failing quality tests, and communication breakdowns with the supplier. As a result, manufacturers see a loss in revenue, dissatisfied customers, and a damaged reputation. Unfortunately, this is a common scenario many manufacturers face when venturing into overseas production.

The goal of this blog is to introduce 5 tips to help reduce the risk of manufacturing your products overseas. Whether you’re a small business owner or a procurement manager for a large corporation, finding the right supplier and ensuring a smooth production process is crucial. By implementing these tips, you can mitigate risks, maintain high-quality standards, and ensure your products are shipped on time.

Tip 1: Conduct Thorough Supplier Research

Conducting thorough research when selecting an overseas supplier is crucial to mitigate risks and ensure a smooth manufacturing process. Without proper vetting, you may encounter issues such as substandard product quality, unreliable delivery schedules, and even unethical business practices. Detailed research helps you find a supplier who not only meets your quality and delivery requirements but also aligns with your business values and goals.

Start by gathering as much information as possible about potential suppliers through online research. Look for reviews and ratings on industry websites, forums, and social media platforms. Pay attention to both positive and negative feedback, as this can provide insights into the supplier’s reliability, quality, and customer service.

Request References

A reputable supplier should be willing to provide references from previous or current clients. Reach out to these references to gain firsthand accounts of their experiences. Ask specific questions about the supplier’s adherence to quality standards, delivery timelines, and responsiveness to issues. Speaking directly to other companies can help you gauge the supplier’s reliability and performance.

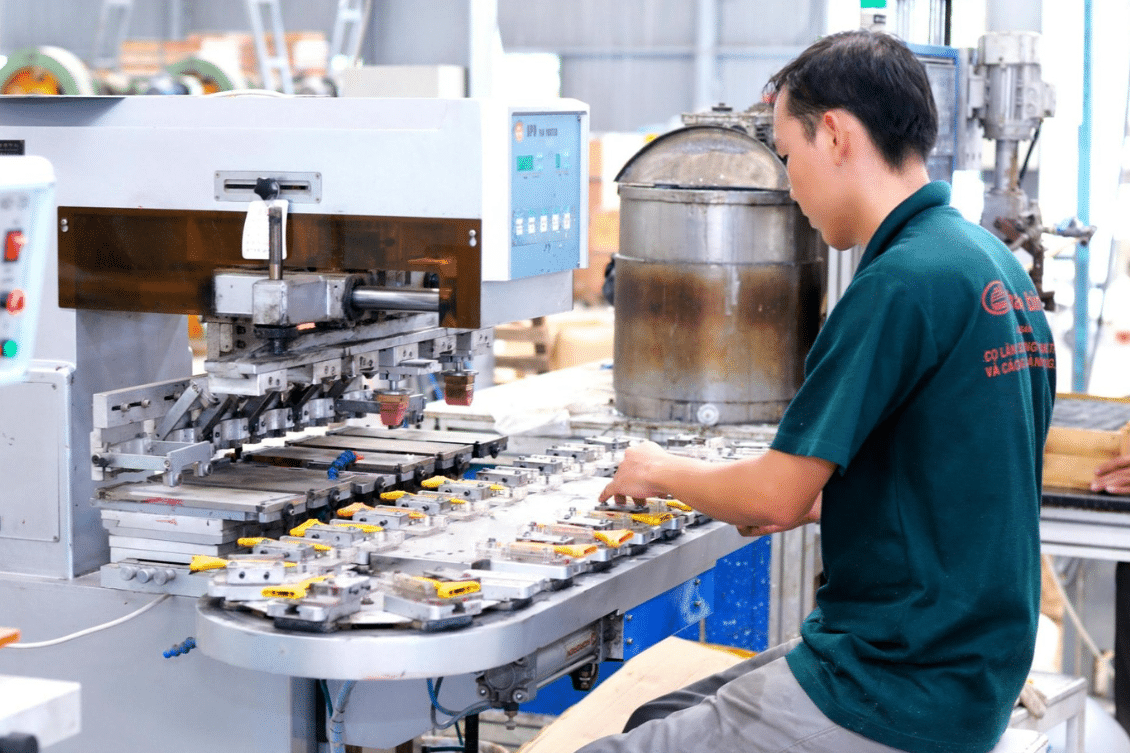

Visit the Supplier

During COVID, this might not have been possible depending on where the supplier was located. Now, there is no excuse not to visit a supplier you chose to build your product. Visiting your supplier allows you to see their operations firsthand, assess their production capabilities, and ensure they meet your standards. During the visit, observe the working conditions, machinery, and processes in place. This will give you a better understanding of the supplier’s capacity to handle your orders and maintain consistent quality.

By conducting thorough research and utilizing these strategies, you can significantly reduce the risks associated with overseas manufacturing. Finding a trustworthy and capable supplier sets the foundation for successful and sustainable production, ensuring that your products meet quality standards and are delivered on time.

Tip 2: Establish Clear Communication Channels

Clear and effective communication is the cornerstone of a successful overseas manufacturing partnership. It helps prevent misunderstandings, ensures that both parties are aligned with expectations, and maintains the quality and timeliness of production. Without clear communication, small issues can quickly escalate into major problems, leading to delays, quality issues, and increased costs.

Here are three things you should do to make sure communication is clear.

Set Up Regular Meetings and Updates

Regular communication helps build a strong working relationship with your supplier and keeps everyone on the same page. Schedule consistent meetings to discuss project progress, address any concerns, and plan upcoming activities. These meetings can be weekly, bi-weekly, or monthly, depending on the complexity and stage of your project. Regular updates help in the early identification of potential issues, allowing for prompt resolution.

Ensure There Are No Language Barriers

Language barriers can lead to significant misunderstandings and errors. Ensure that both parties can communicate effectively in a common language. If necessary, employ professional translators or bilingual staff to facilitate communication. This is particularly important for technical discussions and contract negotiations, where precise language is critical. Clear communication reduces the risk of misinterpretations and ensures that all parties fully understand the requirements and expectations.

Document All Agreements and Expectations

Documenting all agreements and expectations is essential for clarity and accountability. Ensure that every aspect of your collaboration is written down, including product specifications, quality standards, delivery schedules, and payment terms. Use contracts, emails, and shared documents to record these details. Written documentation serves as a reference point for both parties, helping to resolve disputes and misunderstandings quickly and effectively.

By establishing clear communication channels and following these key points, you can foster a strong, transparent, and effective relationship with your overseas supplier. This not only prevents misunderstandings and ensures quality but also builds a foundation for long-term collaboration and success in your manufacturing endeavors.

Tip 3: Implement Quality Control Measures

Maintaining product quality is key when manufacturing overseas. Ensuring consistent quality can be challenging due to distance, differing standards, and communication barriers. Effective quality control measures help mitigate these challenges, ensuring that your products meet your standards and satisfy your customers. Implementing robust quality assurance processes not only safeguards your brand’s reputation but also reduces costs associated with returns, rework, and dissatisfied customers.

Here are a couple of things to keep in mind when looking to keep a high level of quality.

Conduct Regular Quality Inspections

Regular quality inspections are essential to ensure that your products meet specified standards throughout the production process. Schedule inspections at various stages of production, from raw materials to finished goods. These inspections can help identify issues early, allowing for corrective actions before products are shipped. Create a detailed checklist based on your quality criteria to guide the inspection process and ensure consistency.

Set Up a Feedback Loop for Continuous Improvement:

Establishing a feedback loop allows for continuous improvement in your manufacturing processes. Collect feedback from your quality inspections, third-party audits, and customer reviews. Analyze this data to identify recurring issues and areas for improvement. Work collaboratively with your supplier to implement corrective actions and enhance processes. Regularly review and update your quality standards and inspection procedures based on feedback and evolving industry standards.

By implementing these quality control measures, you can maintain high product quality when manufacturing overseas. Regular inspections, third-party services, local oversight, and continuous improvement processes ensure that your products consistently meet your standards, thereby protecting your brand’s reputation and ensuring customer satisfaction.

Tip 4: Develop Strong Relationships with Suppliers

Nurturing strong relationships with your suppliers is crucial for successful overseas manufacturing. While contracts are important, it is the relationships built on trust and partnership that truly ensure smooth operations and long-term success. Strong supplier relationships facilitate better communication, quicker problem resolution, and a more collaborative approach to achieving mutual goals.

In order to develop a stronger relationship with your supplier, you need to focus on these points.

Treat Suppliers as Partners, Not Just Vendors

Approach your suppliers as partners rather than just vendors. This mindset shift creates a sense of shared responsibility and mutual investment in success. When suppliers see themselves as partners, they are more likely to go above and beyond to meet your needs, proactively address issues, and contribute to the overall success of the project.

Foster Open Communication and Mutual Respect

Open communication and mutual respect are the foundations of a strong supplier relationship. Encourage transparent and honest dialogue about expectations, challenges, and goals. Listen actively to your supplier’s concerns and suggestions. Show appreciation for their efforts and respect their expertise. Mutual respect and understanding strengthen the bond and create a positive working environment.

Visit Suppliers Regularly

Regular visits to your supplier’s facilities can significantly strengthen your relationship. These visits provide opportunities to build rapport, understand their operations better, and address any concerns in person. Face-to-face interactions help develop a deeper connection and trust, making it easier to collaborate effectively. During visits, take the time to meet with various team members and acknowledge their contributions.

Provide Constructive Feedback and Recognize Good Performance

Constructive feedback and recognition play vital roles in nurturing strong supplier relationships. Provide clear and actionable feedback on areas needing improvement, and do so in a supportive manner. Equally important is recognizing and rewarding good performance. Acknowledging your supplier’s efforts and successes fosters goodwill and motivates them to maintain high standards.

By treating suppliers as partners, fostering open communication, visiting regularly, and providing constructive feedback and recognition, you build strong, trust-based relationships that go beyond contractual obligations. These relationships are invaluable in navigating the complexities of overseas manufacturing, ensuring consistent quality, timely delivery, and a collaborative approach to overcoming challenges. In the long run, strong supplier relationships can be more beneficial and resilient than the most meticulously drafted contracts.

Tip 5: Diversify Your Supplier Base

Diversifying your supplier base is a crucial strategy for mitigating risk in overseas manufacturing. Relying on a single supplier can leave your production vulnerable to disruptions due to various factors such as geopolitical issues, natural disasters, or financial instability. By having multiple suppliers, you can ensure continuity and stability in your supply chain, enhancing your ability to respond to unforeseen events and maintain consistent production.

Avoid Putting All Your Eggs in One Basket

Relying on a single supplier can be risky. If that supplier encounters problems, your entire production can come to a halt. By diversifying your supplier base, you spread the risk across multiple sources, ensuring that if one supplier faces issues, others can continue to meet your needs. This approach protects your business from supply chain disruptions and potential losses.

Source From Multiple Suppliers in Different Regions

Sourcing from suppliers in different regions further reduces risk by diversifying geographical exposure. Different regions may face different challenges, such as political instability, natural disasters, or economic fluctuations. By having suppliers in various locations, you can mitigate the impact of regional issues on your supply chain and maintain a steady flow of materials and products.

Develop Backup Suppliers for Critical Components

Identify the critical components of your products and develop backup suppliers for these items. Having secondary suppliers ensures that you have alternatives ready if your primary supplier cannot deliver. This is particularly important for components that are vital to your product’s functionality and quality. A well-prepared backup plan minimizes downtime and keeps your production line running smoothly.

Startups Need to Diversify Their Supply Chain Too

It’s important to note that you don’t need to be a large manufacturer to diversify your supply chain. Startups and small businesses should also prioritize diversification to mitigate risks. Even with limited resources, small companies can establish relationships with multiple suppliers and develop contingency plans. This proactive strategy can provide stability and growth opportunities for startups, helping them navigate challenges more effectively.

By diversifying your supplier base, sourcing from multiple regions, developing backup suppliers, and regularly assessing your supplier portfolio, you can significantly reduce the risks associated with overseas manufacturing. This approach ensures a more resilient supply chain, capable of withstanding disruptions and maintaining consistent production quality and timelines. Diversification is a critical strategy for businesses of all sizes, providing the flexibility and security needed to succeed in a competitive global market.

Conclusion

Navigating the complexities of overseas manufacturing can be daunting. By following these tips, manufacturers can significantly reduce the risks associated with overseas production, ensuring high-quality products, timely delivery, and a robust supply chain. Whether a large corporation or a startup, taking proactive steps in supplier research, communication, quality control, relationship building, and diversification will pave the way for successful and sustainable overseas manufacturing. Start implementing these strategies today to safeguard your production processes and achieve consistent, high-quality results.

Are you interested in OpenBOM? Reach out to us.

By: Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.