Digital transformation is coming to every aspect of manufacturing business solutions. In my previous articles, I discussed what is Digital BOM, how OpenBOM is extending digital workflows with multiple services, and building a multi-view BOM to help manufacturing companies manage a fully digital set of product information including BOMs, items, connected documents to make it available downstream for procurement and operation.

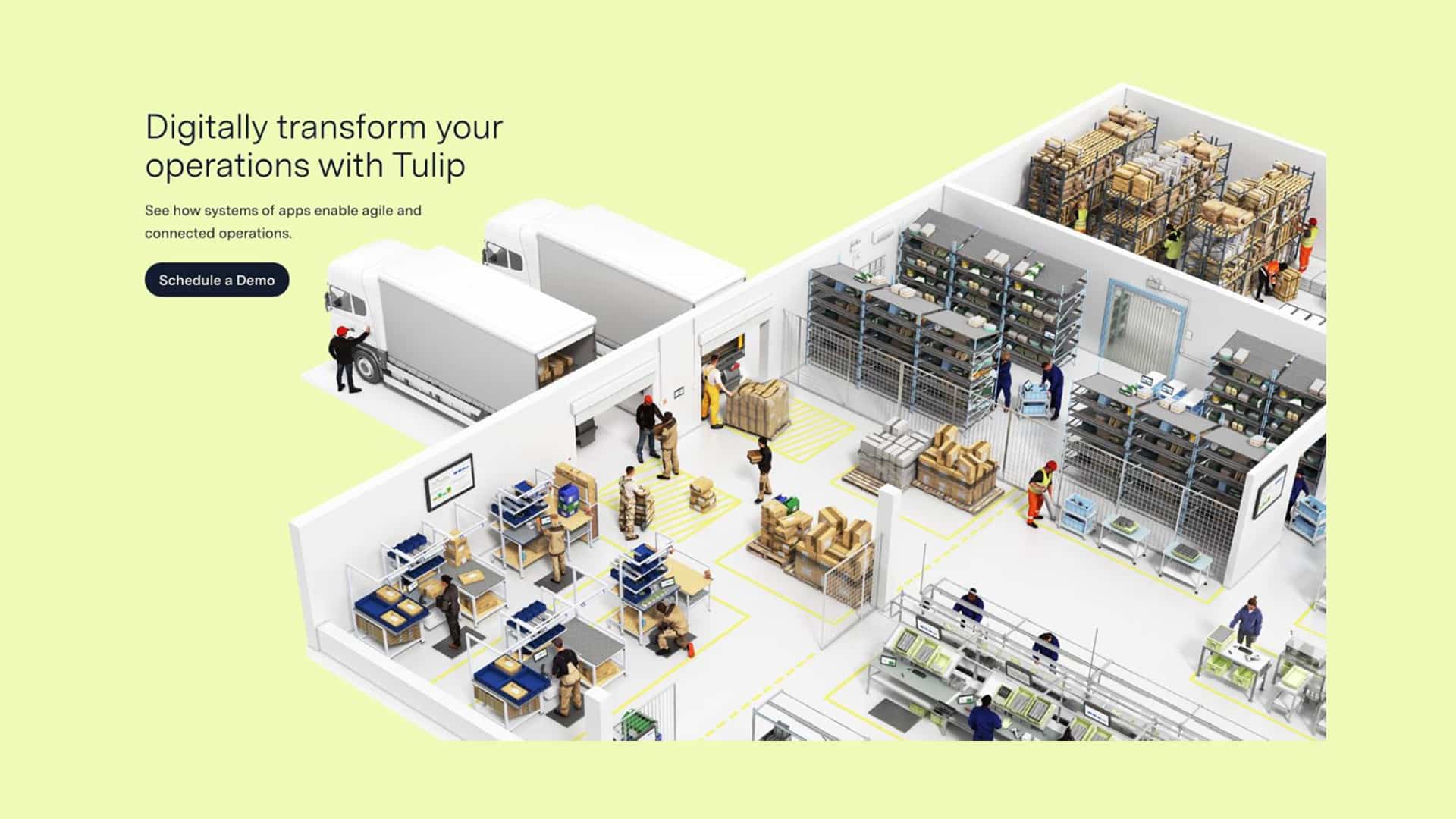

Today, I want to talk about digital transformation in manufacturing execution and introduce you to Tulip – a revolutionary online platform to solve your operational challenges.

Tulip Platform

Tulip helps you digitally transform your manufacturing operations by providing a solution for work instructions management, production visibility, machine monitoring, operations training, and other aspects of frontline operations.

Tulip is democratizing operational technology by providing a cutting edge no-code OT platform to support digital transformation in manufacturing operations. Check the Tulip story here. Here is my favorite passage:

According to recently published Gartner research, the leading reason companies invest in MES is to improve the ability of employees to make key decisions for themselves. This means that organizations invest in digital systems for the same reasons no-code is changing the future of work. No-code allows people to take ownership of the tools and the data workflow that they’re generating. It gives power back to the shop floor workers.

Here’s a quick example of No-code for OT – Tulip’s application library, a collection of apps based on manufacturing’s best practices and use cases. The library has pre-designed, configurable logic commands and UI interfaces that are essentially ready-to-go apps for various types of operations. And this can all be done without writing a single line of code or implementing system integrations.

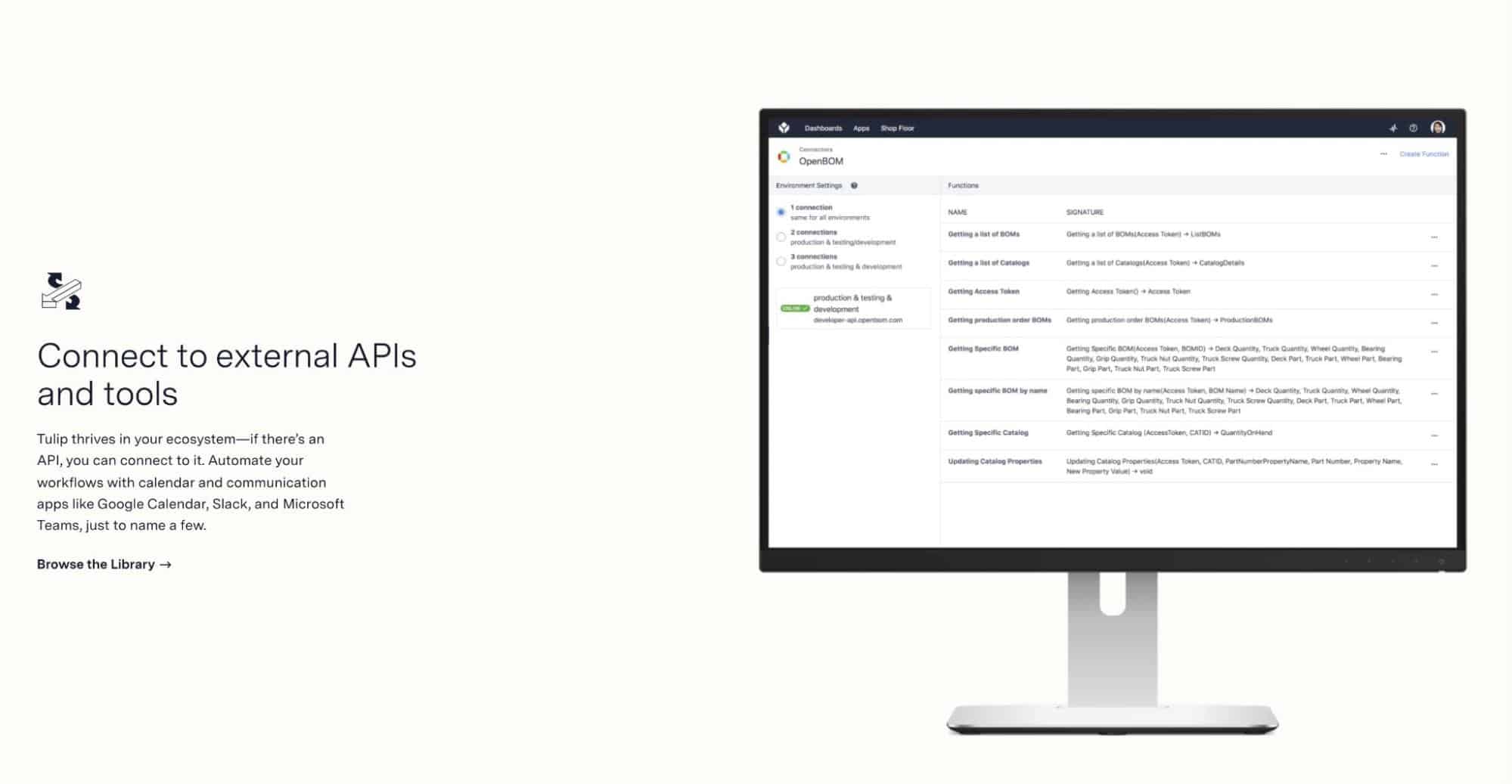

Tulip Library and OpenBOM Connector

Tulip library provides a set of predefined building blocks and connectors that can help you build a flexible and configurable solution to any problem. OpenBOM Connector integrates OpenBOM with Tulip using Tulip’s HTTP Connectors to pull information on Bill of Materials directly from OpenBOM. The integrations enable the digital chain of information by connecting your engineering office and information directly with your manufacturing operations. It makes digital BOM available directly with the apps to everyone on the shop floor – no mistakes, no files transfers, no spreadsheets printouts. This is how Tulip builds end-to-end integrations.

Watch the video of OpenBOM connector tests using Tulip interfaces:

Revolution – Digitally Connected Services

Tulip’s connection with OpenBOM gives you a great example of the modern trend in developing a new type of online service, replacing traditional legacy enterprise software. The entire paradigm of existing tools PDM, PLM, ERP, MES is going through the transformation process as it happened with other enterprise software – in marketing, CRM, and other disciplines. In the past, MEST systems required onsite IT, complex enterprise setup, implementation, and deployment. Now it is available via a set of agile connected services with no-code configuration capabilities – this is a modern “no MES” platform. This is the same trend we can see with the digital transformation of design, engineering, product lifecycle, and manufacturing resource planning. OpenBOM provides an online digital platform to capture engineering information using multiple integrations with all existing CAD systems, allowing management of all product, engineering, and procurement data integration – “no PLM” platform. OpenBOM online service provides needed information to the Tulip platform via online real-time HTTP connectors we demonstrated above.

Conclusion

Digital transformation is coming to manufacturing and it is not limited to a specific space in manufacturing such as design (CAD), engineering and product lifecycle systems, procurement, manufacturing operations, and other services. A new type of applications are replacing old legacy siloed enterprise software with online service platforms that are connected using a set of no-code services in a flexible and configurable fashion. Check out more about Tulip and OpenBOM and how they can work together to provide a digital data continuum – no papers, chalkboards, excels, emails, and printouts of data. You have full control of information that is available at your fingertips.

For more information about Tulip, navigate to this link.

Check out what OpenBOM can do for you and REGISTER FOR FREE and start your 14-day trial today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.