In today’s fast-paced business environment, organizations are constantly seeking ways to enhance their operations and streamline processes. The goal is to achieve one of these three things – (1) earn more $$$, (2) save cost, and (3) mitigate risks. But, to make it happen, a company must be translate it into activities that related to data management, optimization of information flow and orchestration of people work. At OpenBOM we are always thinking about how to help our customers achieve these goals. And this is exactly where we come with the understanding of OpenBOM ROI.

Let’s talk about it, but start from a traditional PLM (product lifecycle management), which is for years was a way to organize data for engineering and manufacturing related processes. The traditional PLM approach was to find a balance between cost and efficiency. PLM projects were often seen as a “cost to run the business,” while the focus was primarily on improving existing processes for greater efficiency. In the recent years, I can hear more and more conversations about focusing on PLM strategy as a way to start PLM implementation. This is a good move.

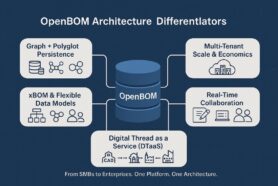

At OpenBOM we take a different approach and new perspective on ROI in the new digital world of PLM. OpenBOM, a cloud-based SaaS gives you a unique set of tools and capabilities to play a role in this transformation. Digital transformation won’t happen overnight, but it is a journey that companies need to start.

In my article today, I want to talk about OpenBOM ROI and how you can make an assessment of OpenBOM implementation Return on Investment (ROI). It is a crucial benchmark to determine whether the investments in OpenBOM can be justified.

The Three Dimensions of OpenBOM ROI

While thinking about OpenBOM implementation, you can consider the following dimensions of OpenBOM usage and ROI assessment.

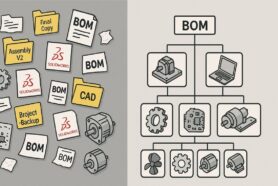

1. Transitioning from Spreadsheet Chaos to Digital Data

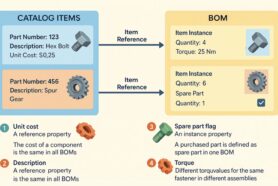

One of the most significant challenges organizations face is the proliferation of data in Excel spreadsheets and scattered documents. OpenBOM takes data management to the next level by providing a place to host CAD files and related documents, to create a digital representation of Bill of Materials (BOM), replacing the chaos of disconnected spreadsheets and other files. This transformation lays the foundation for improved data accuracy, accessibility, and collaboration.

A single place for digital information eliminates mistakes and puts everyone in the company “on the same BOM” with all related information. A single mistake in production planning, miscalculation of cost, or sending the wrong PDF drawing to a contractor can pay off an OpenBOM subscription for the next year.

As an example check the experience of VarTech saving 2 hours of engineering time with OpenBOM every day. “I remember we caught a $1000 mistake the first month we had OpenBOM. Our Excel had not been updated. OpenBOM literally paid for itself that month.”

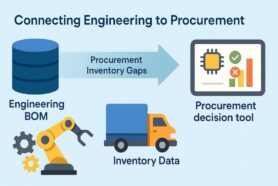

2. Seamless Integration with Legacy and Modern Systems

OpenBOM is not limited to just modern systems but also offers seamless integration with legacy applications, including desktop CAD tools. Additionally, it connects to a wide range of modern services, such as cloud design platforms like Autodesk, Onshape, SaaS Enterprise Resource Planning (ERP) systems, and tools for frontline workers. This comprehensive integration ensures that data flows seamlessly across different systems and departments, reducing bottlenecks and errors.

Making manual operations to save data from CAD systems to BOMs, creating derivative files and many other steps is the work engineers don’t like to do. Also, manual work is prone to errors and mistakes. OpenBOM solves this problem by automating all these processes.

Check here the story about OpenBOM and Gates Underwater products. “The OpenBOM Team product is a good fit for us as a company. We have Engineers on CAD, folks in manufacturing and assembly, and recently incorporated OpenBOM in our supply team.” John goes on to say that he appreciates how OpenBOM fits the size of his business as they scale, “I did not anticipate the overall benefit of the Solidworks integration” he says. “It was a big WOW! moment. Since then the scope of what we put in OpenBOM has grown. We can control more information, specifications, and requirements. OpenBOM forces adherence to a process! Bottom line,” says John, “OpenBOM is a perfectly suited, good-value product. It’s an excellent match to our needs.”

3. Streamlining Data and Unlocking Analytics Potential

OpenBOM’s power extends beyond data storage and integration. It streamlines data from various representations and services, creating a unified and structured database. This consolidated data becomes the cornerstone for advanced analytics and graph data science applications, enabling organizations to gain valuable insights into their product development processes.

Check the story of Xtend Robotics delivering robots using OpenBOM helping to manage production and streamlining data processes from design to production.

“What I like the most about OpenBOM is the ability to model and plan for ALL aspects of our robots, and not just those items confined to traditional CAD. Our wire harness and PCBs are all designed separately and then brought together in OpenBOM to form a complete multidisciplinary BOM of our entire buy-level product. We can manage non-modeled items like adhesive or labor easily in OpenBOM, create a new purchased BOM and manipulate options and variations. As our company and products mature, we are managing inventory and creating external and internal POs to drive manufacturing. All with one item master definition and never any duplicates!”.

Implementing OpenBOM ROI in Phases

The journey to achieving OpenBOM ROI is not an all-or-nothing endeavor. It can be effectively realized through a phased, agile approach:

- Preparation and Digital Capture: Begin by preparing your organization for digital transformation. Capture existing data and establish a solid foundation for further integration.

- Basic Digital Projects and Digital BOM: Start with essential digital projects, such as digitizing Bill of Materials. This step introduces your team to the new way of working with digital data.

- Data Capture: Expand data capture efforts across your organization. This phase ensures that data from various departments is incorporated into the digital ecosystem.

- Planning and Production: With a robust digital infrastructure in place, organizations can now leverage OpenBOM to streamline planning and production processes, reducing time-to-market and costs.

Throughout this phased implementation, OpenBOM provides the necessary practices and training to facilitate a smooth transition.

Conclusion:

OpenBOM helps you to start the transforming of your manufacturing business. OpenBOM offers a rapid and efficient path to achieving ROI in the digital age. By converting data into digital representations, seamlessly integrating with existing and modern systems, and streamlining data for analytics, OpenBOM empowers organizations to make informed decisions and optimize their product development processes. The phased implementation approach ensures that organizations can start realizing benefits quickly and continue to grow their ROI over time. OpenBOM is not just about “doing things right”; it’s about “doing the right things” in the ever-evolving landscape of product development and PLM.

REGISTER FOR FREE and check how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.