Manufacturing is all about getting products to market as quickly and efficiently as possible. However ensuring that the supply chain runs smoothly can be a daunting task, especially when it involves multiple partners. By unlocking the power of design and manufacturing partnerships, businesses can streamline their supply chain and improve overall efficiency.

As a manufacturer, you know that having a streamlined and efficient supply chain is key to keeping your business running smoothly. But did you know that working with design and manufacturing partners can help you achieve this? By collaborating with partners who can provide expertise in specific areas of manufacturing, you can streamline your process and improve your bottom line. In this blog post, we’ll explore how OpenBOM helps you to streamline your processes with design and manufacturing partners and share some tips on how to digitally transform your business using cloud-native PDM and PLM solutions like OpenBOM.

Upstream and Downstream Collaboration

Every manufacturing company is constrained by its ability to develop new products and services and make fast product delivery to the market. In the past, manufacturing companies were huge facilities heavily integrated and centralized to do everything (from design, components, and final assemblies). These days these fundamentals are changing. Manufacturing businesses are turning into huge networks with high-level dependencies and relationships both upstream and downstream.

Modern product complexity requires collaborative relationships in multi-disciplinary design teams working on mechanical, electronics, and software components, integrating cloud services for customers. To design such products, you need to have a team of skilled people working together. Talent shortage combined with the need to provide some unique skills is pushing companies to search for engineers everywhere. How can these distributed teams deliver solutions together? There is a huge demand for tools capable of supporting design and engineering collaboration. Time is a killer. These people need to work and collaborate in real time to hit deadlines. Agile product development is key to making it happen.

To build products companies need to manage the delivery pipeline, optimize supply chain performance, and look for components and assembly facilities operating smoothly without delays. With recent challenges in the supply chain, chip shortages, lockdowns, delivery delays, and many other factors, companies need to find a way to optimize their downstream processes, work pro-actively ahead of time, make orders for long-lead-items and optimize data sharing in downstream relationships – from engineering teams to procurement and contract manufacturing facilities.

Single Source of Truth and Connected Experience

Data is the foundation of efficient supply chains in both organizing upstream and downstream processes. Fragmented and siloed data leads to mistakes, delays, and unplanned expenses. How to solve the problem? You need to build a process around the data.

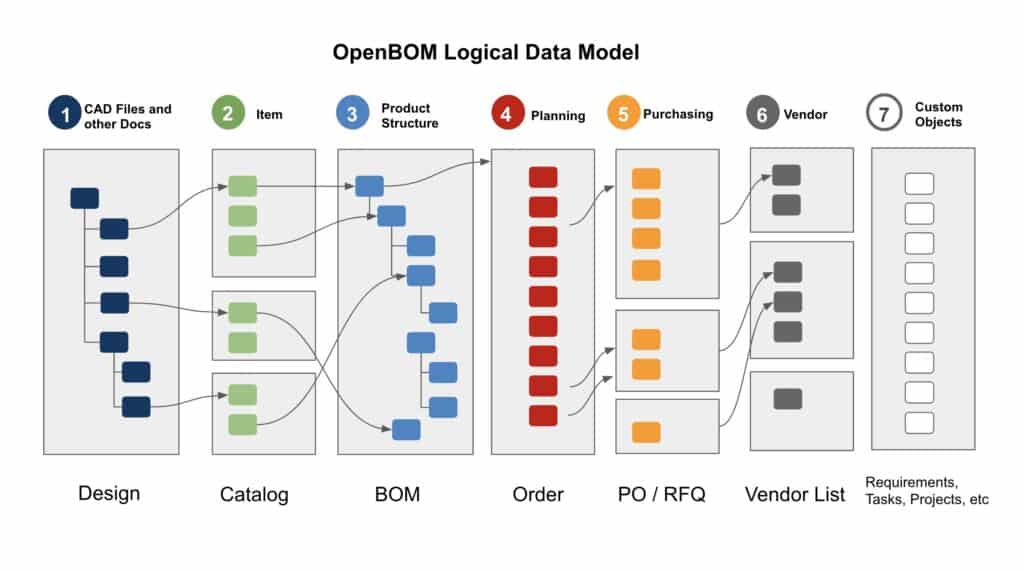

Therefore the first step in organizing truly digital workflows is to think about how to organize the data about the product and to allow everyone to access this information. A single source of truth, which includes a structured set of information connecting items, bills of materials, files, and all related pieces of data together is the key. The picture below shows you a digital workflow and connected information sets OpenBOM provides. An important element of the OpenBOM foundation is a flexible data model allowing an organization and configure information data sets based on each customer’s requirements.

Integrations and Real-Time Data Sharing

While a single source of truth is the foundation of a digital pipeline, nothing exists in isolation. Manufacturing companies are using many other engineering and financial tools. To operate efficiently, there is a need to integrate these tools into a single digital pipeline. Manual processes slow things down, and manual copy-paste of data brings mistakes. Integrations allow you to streamline data handover and automate data transfers. OpenBOM integrations is the foundation of this process.

However, integrating data sources and tools is only the first step. People should be able to get access to the data too. Data sharing across multiple teams and companies is a key element of bringing teams and processes together. OpenBOM gives you real-time data sharing allowing every person to get role-based data access, so everyone will get access to the right data at the right time.

Conclusion:

OpenBOM brings the power of connections to relationships between manufacturing companies and partners both upstream and downstream. The days when companies worked in isolation are coming to the end. Optimizing the supply chain by setting up digital connections with automatic data handover and data transparency is the key to success in business these days. You need to have modern tools to support you. To be fast in new product development, optimize procurement and share data between multiple designs and engineering contractors – this is a short list of values OpenBOM brings to your business. Replacing clunky emails and Excel-driven processes with a digital pipeline is key to success.

REGISTER FOR FREE and start a 14-day trial to check how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.