When working with engineering BOMs (Bills of Materials) derived from CAD assemblies, one common and frustrating issue is the occurrence of cyclic references or loops. These can lead to confusion, errors, and inefficiencies in your design and manufacturing processes. In this article, we break down how cyclic references happen and provide a structured approach to identifying and resolving them using OpenBOM.

Understanding Cyclic References

Cyclic references occur when relationships within a BOM point back to themselves or create an endless loop of dependencies. This problem often arises due to the following reasons:

- Messy CAD Data: Engineering data exported from CAD systems can be inconsistent, especially when part numbers are not assigned correctly.

- File Name Dependencies: Engineers often rely on file names as identifiers. However, file names can overlap (e.g., using the same name for an assembly and a part), leading to circular relationships.

- Configuration Complexity: Part numbers reused across different configurations or versions of components can also result in loops because of the same Part Numbers assigned to multiple configurations .

Why Fixing Cyclic References is Critical

Cyclic references create mistakes in product structures, making it difficult to:

- Generate accurate BOMs for production and procurement

- To allow OpenBOM flattened BOM functionality to work

- Ensure traceability and data integrity.

Resolving these issues early in the design process is essential for ensuring smooth transitions from engineering to manufacturing.

Step-by-Step Guide to Fix Cyclic References in OpenBOM

The following process outlines how to identify and resolve cyclic references in engineering BOMs created from CAD assemblies:

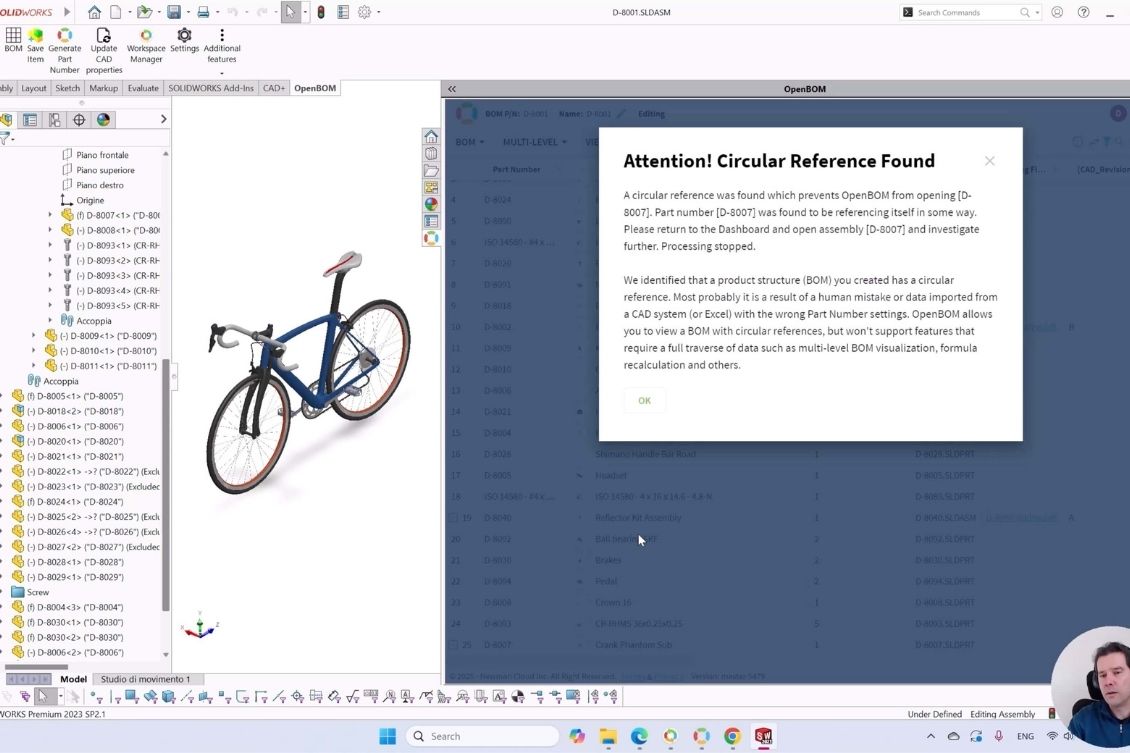

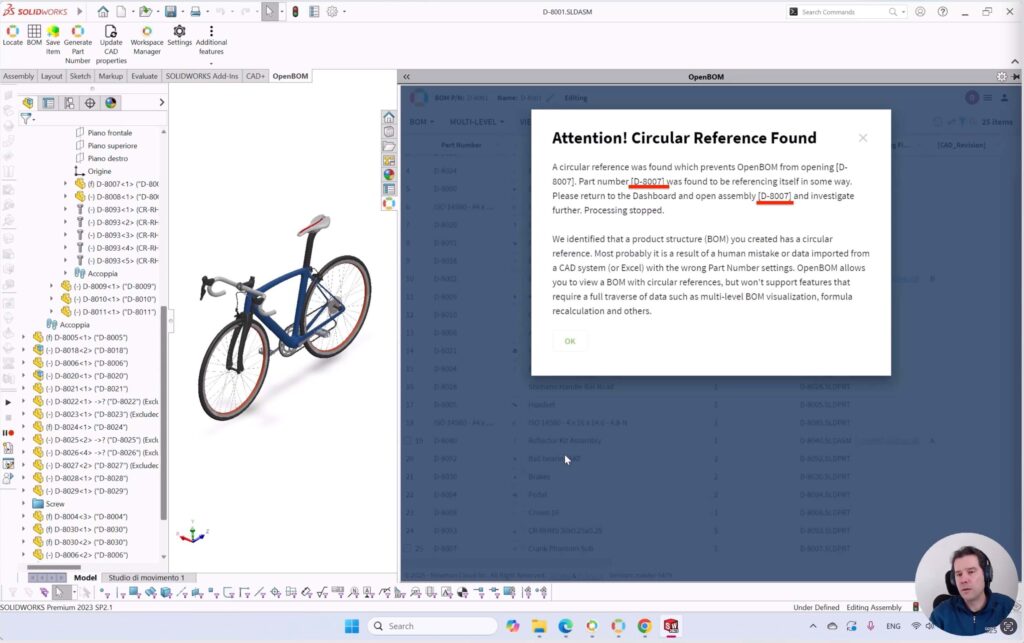

1. Identify Cyclic References

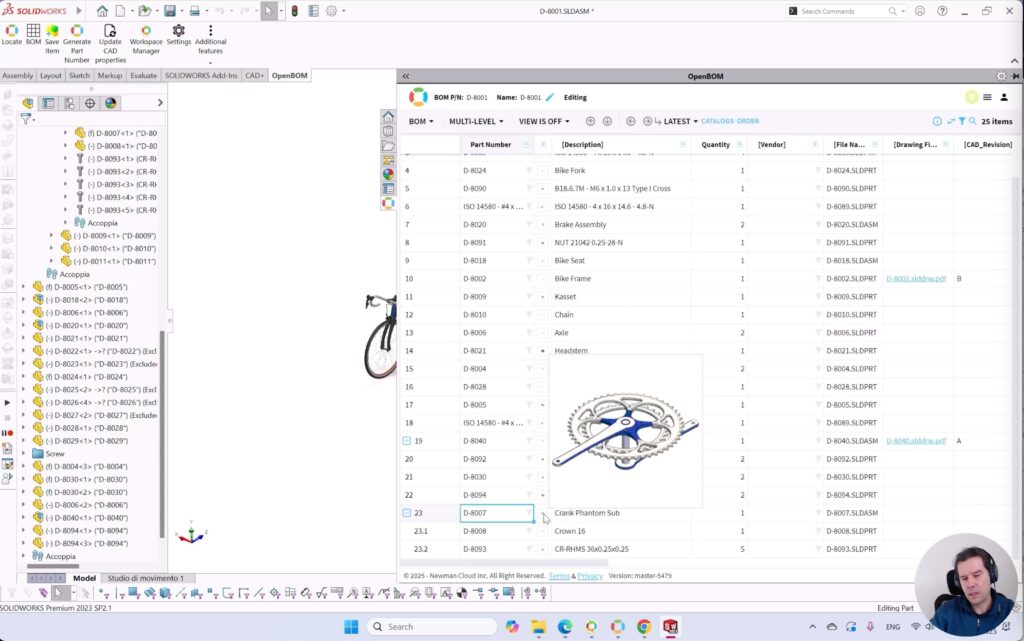

- Use OpenBOM to import the BOM generated from your CAD system.

- Navigate to the BOM and expand sub-level or switch to ‘flattened BOM”

- Check for duplicate part numbers or references that appear multiple times in conflicting roles (e.g., a part listed as both a component and an assembly).

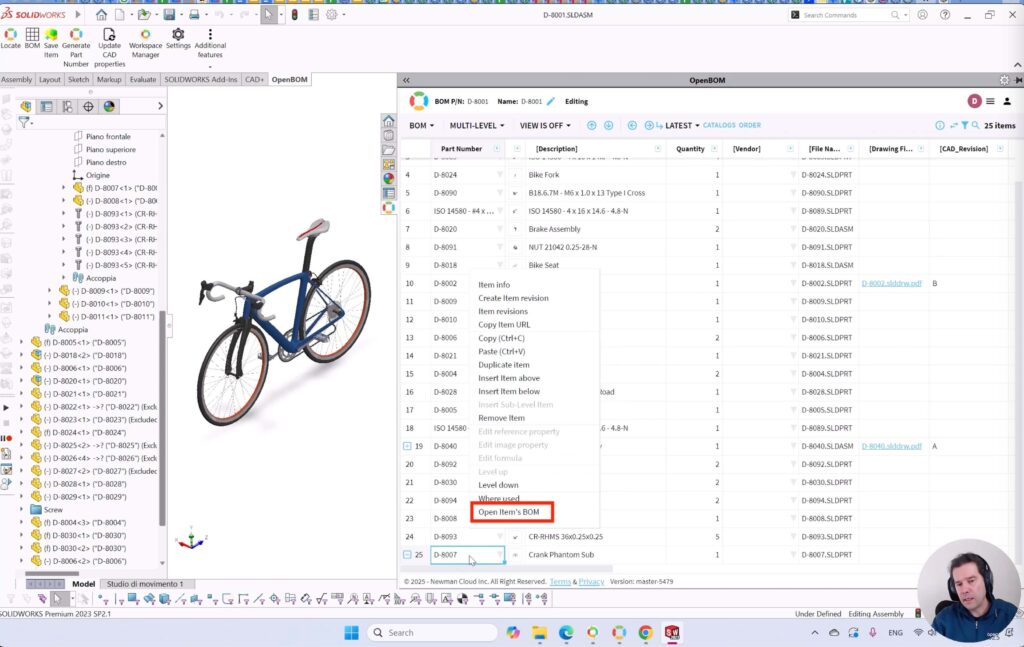

Open the problematic BOM:

2. Review Part Number Assignments

- Ensure that each part and assembly has a unique, clearly defined part number.

- Avoid using file names or generic identifiers as part numbers.

- Create a naming convention that distinguishes between parts, assemblies, and configurations.

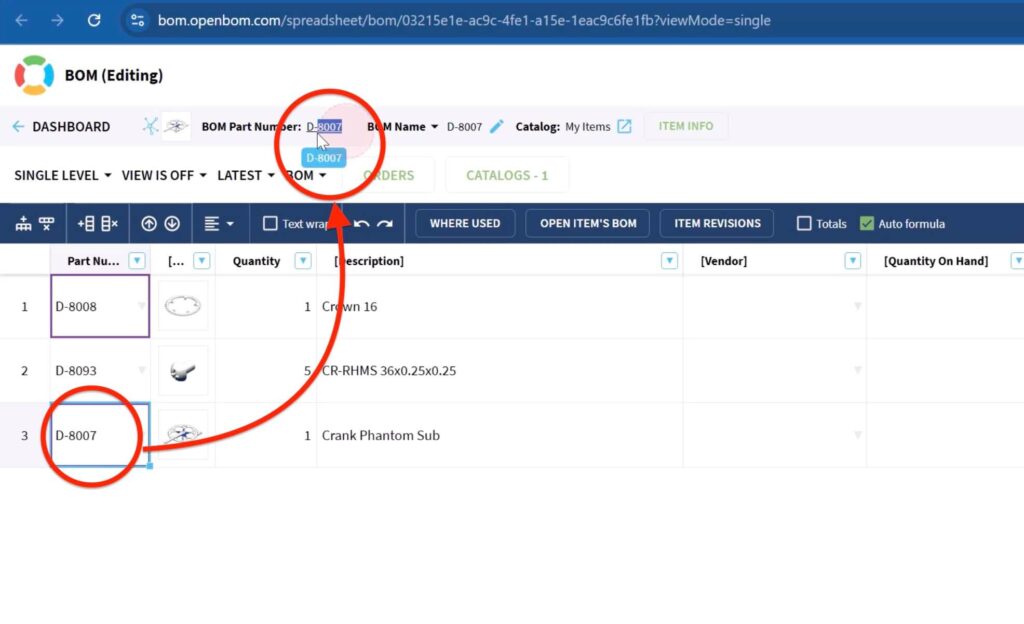

3. Correct Relationships

- Remove duplicate or conflicting references within the BOM.

- Edit or replace part numbers to resolve overlaps.

- For assemblies with cyclic references, redefine parent-child relationships to create a clear hierarchy.

4. Validate the Updated BOM

- Re-import the updated BOM into OpenBOM and confirm that cyclic references are eliminated.

- Use OpenBOM’s validation tools to verify the integrity of the relationships.

- Generate test reports to ensure that all connections align with the intended product structure.

Best Practices to Prevent Cyclic References

- Standardize Part Numbering: Establish a robust part numbering system to avoid conflicts and duplicates. Note, relying on file names for part numbers is a bad idea.

- Organize CAD Data: Maintain clean, well-structured data in your CAD system to minimize errors during BOM generation.

- Use OpenBOM for Real-Time Collaboration: OpenBOM’s cloud-based platform enables teams to collaborate on BOMs in real time, reducing the likelihood of introducing errors.

Watch the Video Tutorial

For a hands-on walkthrough of this process, watch our detailed video tutorial.

This video demonstrates:

- How cyclic references form in engineering BOMs.

- Step-by-step instructions to resolve loops using OpenBOM.

- Tips to streamline your BOM creation process for better results.

Conclusion

Cyclic references in engineering BOMs can disrupt workflows and impact product development timelines. By understanding their causes and following the structured approach outlined above, you can eliminate these issues and ensure smooth collaboration between engineering and manufacturing teams. OpenBOM’s powerful tools and cloud-native platform make this process efficient and effective.

Ready to take control of your BOMs? Visit OpenBOM to learn more and start improving your engineering data today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.