OpenBOM provides seamless integration with many CAD systems, enabling you to extract valuable design data to create a digital Bill of Materials (BOM). This integration not only ensures comprehensive information management but also supports bi-directional collaboration between engineering and manufacturing teams, enhancing efficiency and accuracy.

Here are five simple steps to start using OpenBOM with SOLIDWORKS:

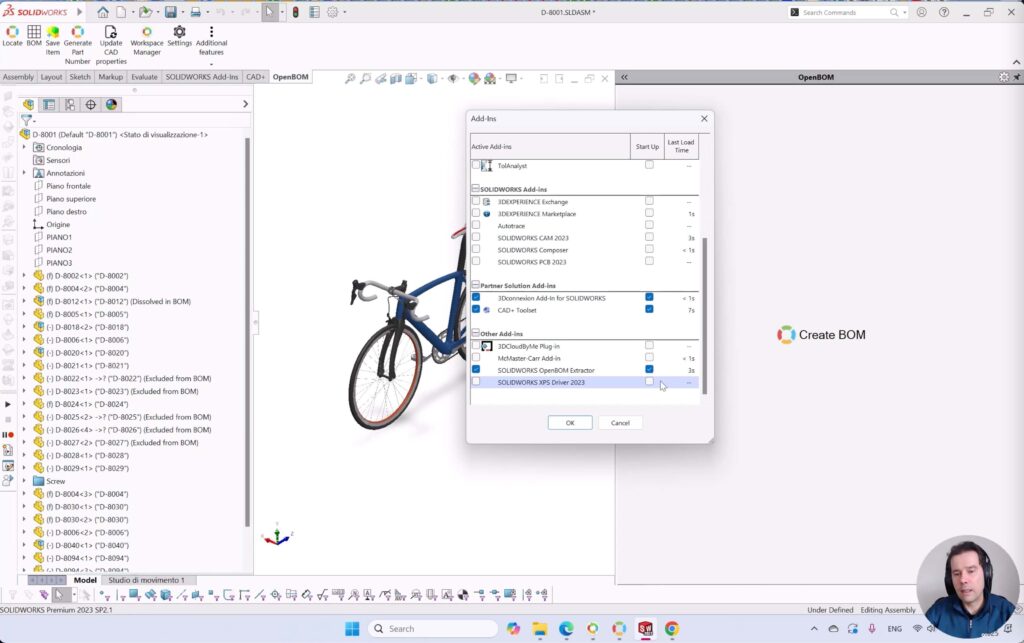

Step 1: Install the OpenBOM Add-in

Visit the OpenBOM website to download and install the OpenBOM add-in for SOLIDWORKS. The add-in provides the tools you need to extract BOM data directly from your SOLIDWORKS assemblies and parts.

Follow the installation instructions, ensuring the add-in is correctly integrated into your SOLIDWORKS environment.

If you don’t see it, check the Add-ins menu in SOLIDWORKS

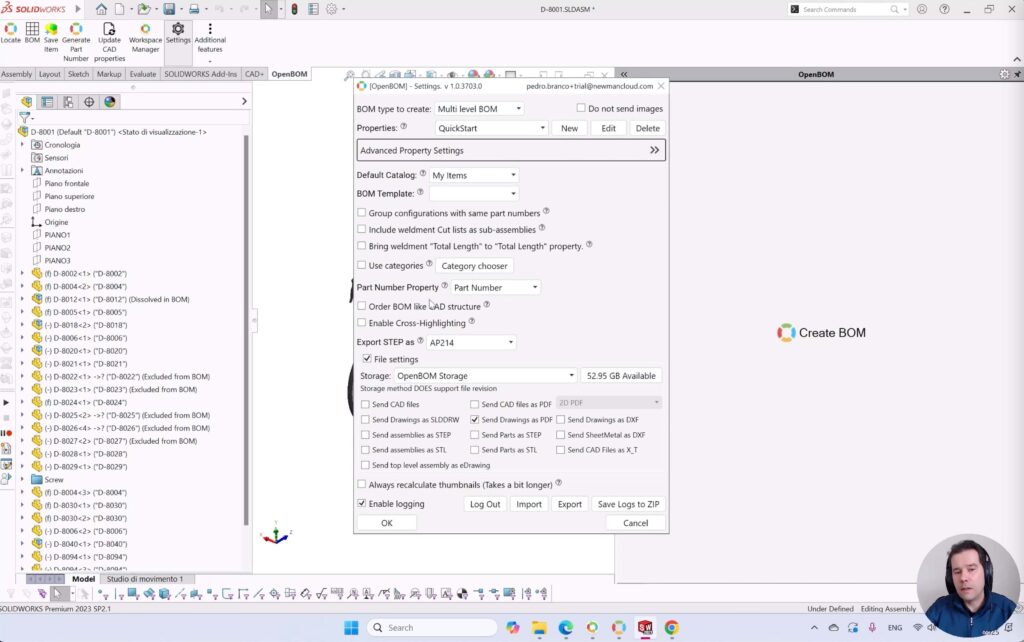

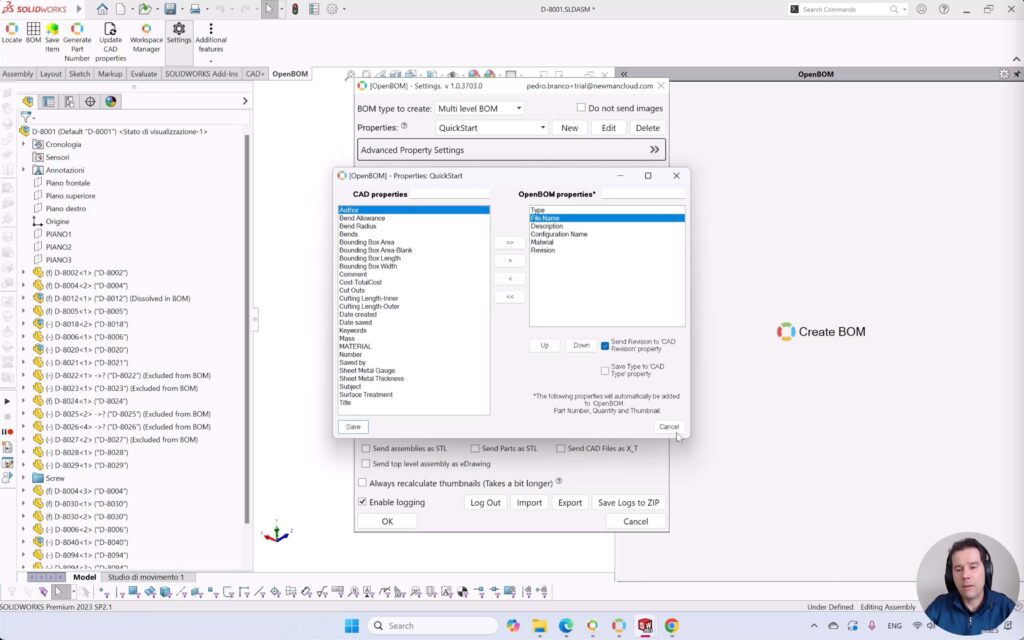

Step 2: Configure Your Settings

Once the add-in is installed, configure your settings. OpenBOM offers a “Quick Start” option with predefined settings to make this process even easier.

These settings are optimized for most users and provide an excellent starting point to ensure your BOM creation workflow is seamless.

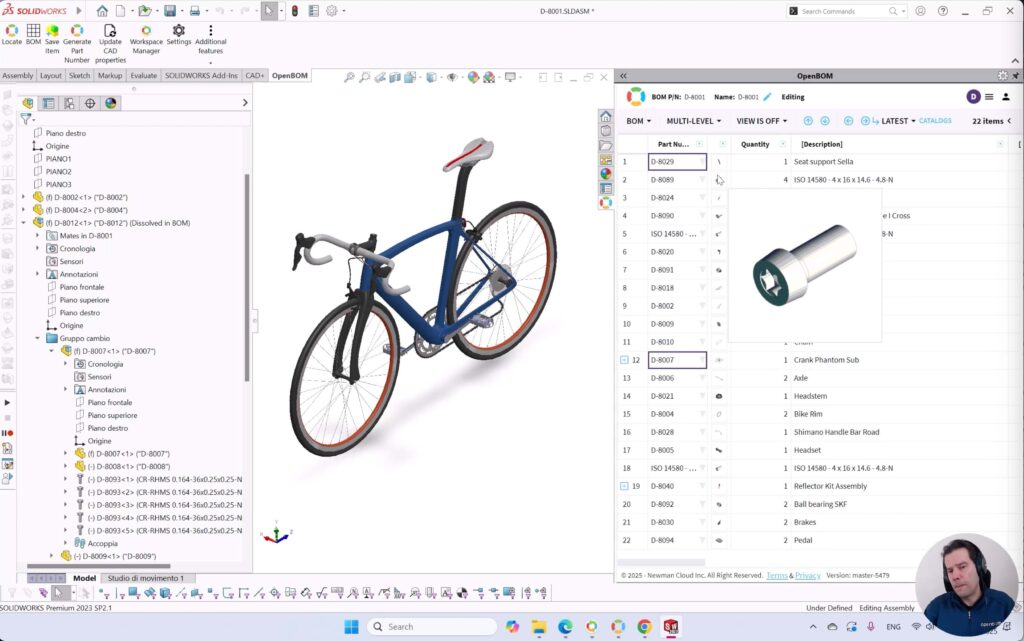

Step 3: Generate the BOM with One Click

Using the “One-Click BOM” function, you can instantly generate a BOM from your SOLIDWORKS design. This function simplifies the process, automatically extracting all relevant data from your model, including parts, assemblies, and associated metadata.

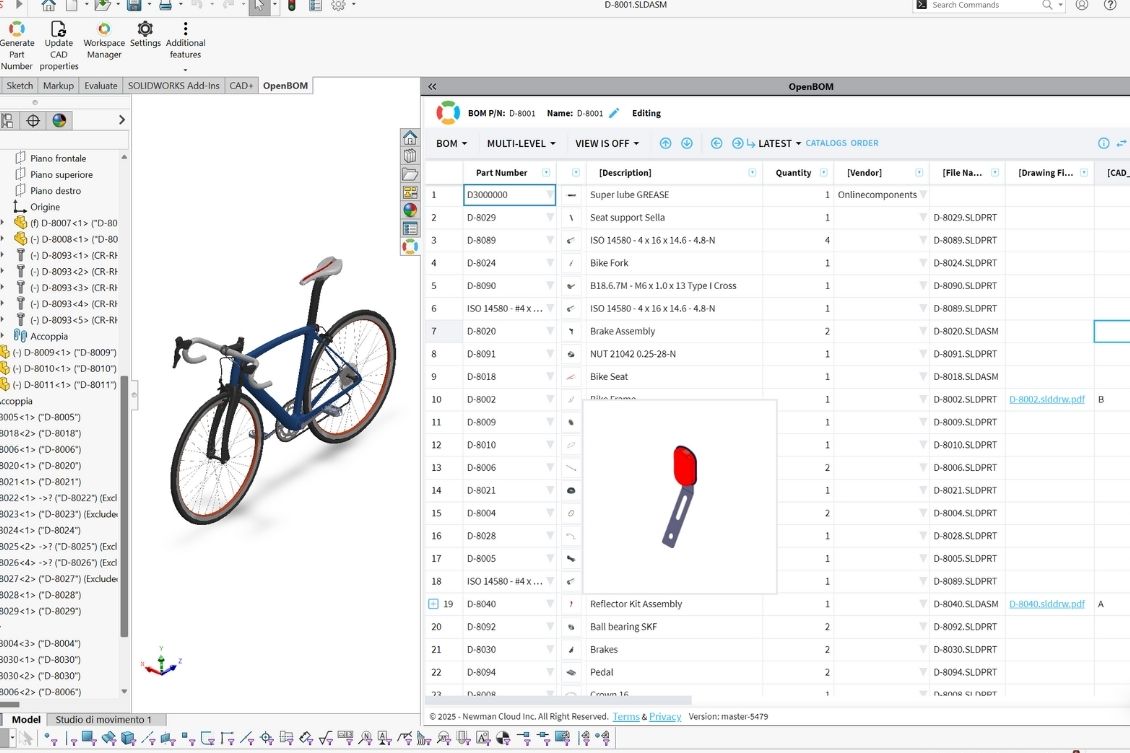

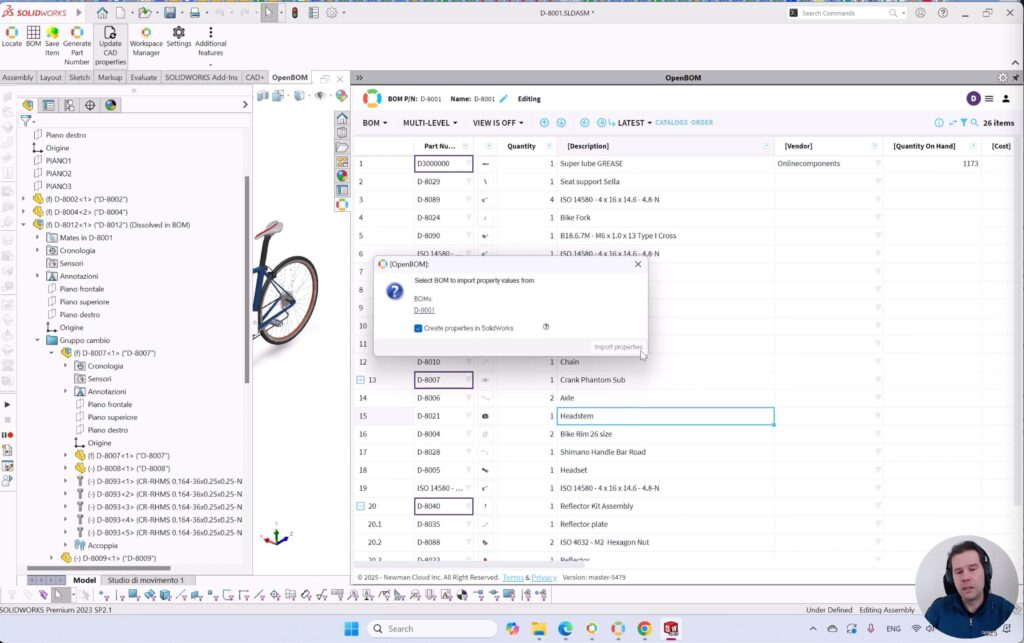

Step 4: Edit and Sync Data

OpenBOM allows you to edit BOM data outside of SOLIDWORKS and sync those changes back to your SOLIDWORKS environment.

This bi-directional capability ensures data consistency and saves you time when managing design iterations or updates.

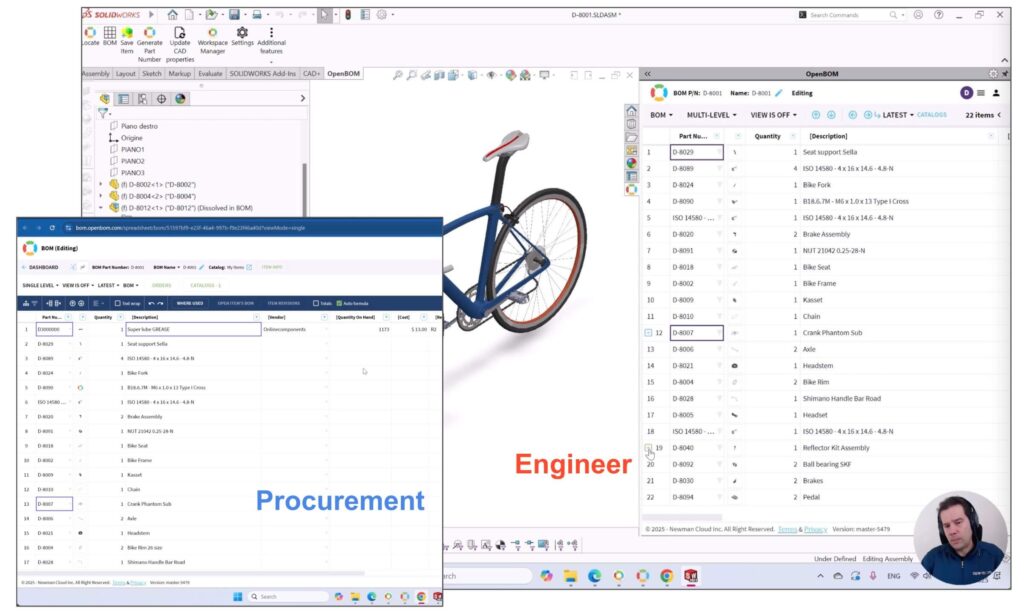

Step 5: Access Data Beyond SOLIDWORKS

With OpenBOM, your data is accessible to team members outside the SOLIDWORKS environment, such as procurement or production teams. They can view derivative files and BOMs in real-time, enabling better collaboration and decision-making without requiring a SOLIDWORKS license.

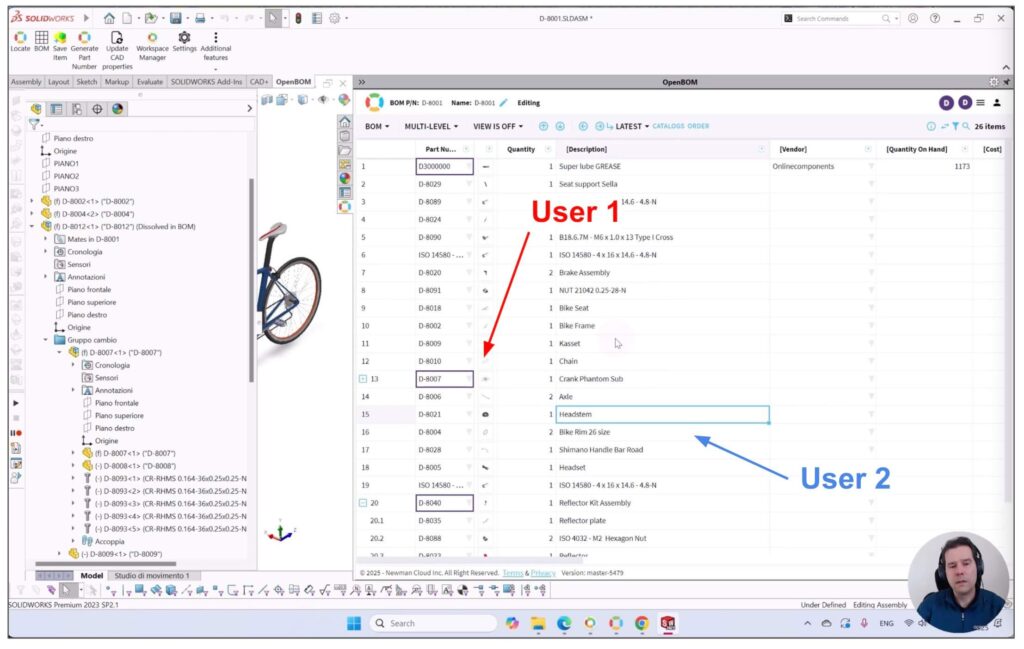

One More Thing: OpenBOM Collaborative Workspace

OpenBOM’s Collaborative Workspace is a unique technology that might remind you of Google Docs or Google Sheets. This feature allows multiple users to make changes simultaneously without locking records. Real-time updates ensure that all team members can see changes as they happen.

For example, an engineer can update a design structure and files, while a procurement team member works on sourcing options simultaneously. Changes made by one user are instantly visible to others, streamlining collaboration and reducing bottlenecks. The Collaborative Workspace highlights contributions from multiple users, ensuring clarity and traceability.

Video Demo

Check the video with the demo of how the process works end to end. It is simple and easy.

Conclusion

OpenBOM’s integration with SOLIDWORKS and other CAD systems allows for seamless data extraction, enabling teams to augment design data with input from engineering, procurement, production, and sales teams.

Its Collaborative Workspace technology further enhances teamwork by providing real-time updates and simultaneous collaboration.

Check out OpenBOM today — REGISTER FOR FREE and give it a try!

Best,Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.