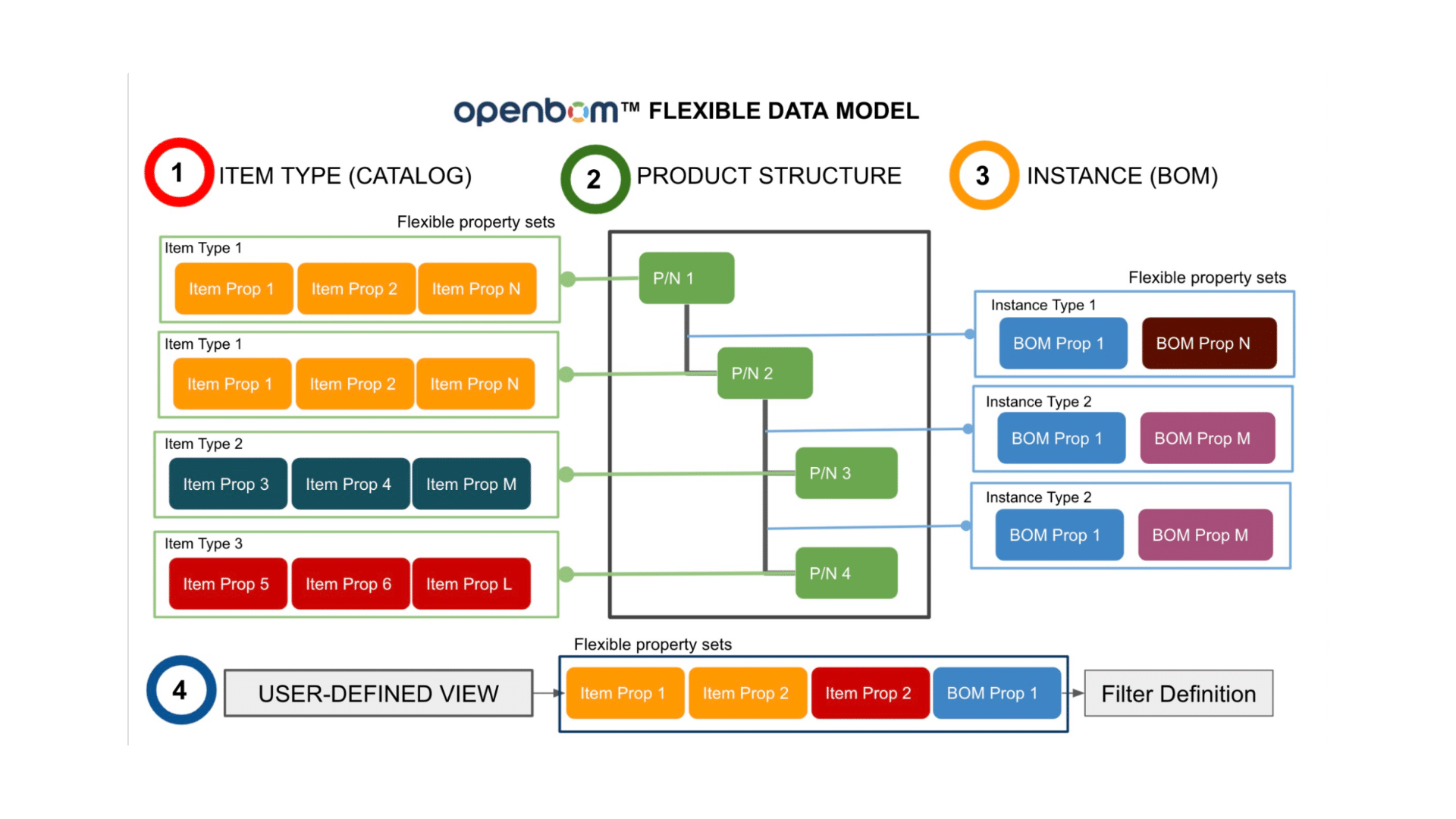

This article is part of OpenBOM’s new video series explaining the basics of OpenBOM, its data modeling organizations, and its fundamental functions. OpenBOM is an online system and its basic data management capabilities are to manage two object types – Items and Product Structure (BOM). The foundational elements are simple and flexible at the same time.

OpenBOM gives you full data modeling flexibility to customize your data in real-time without the need to stop the system. Also, the OpenBOM data model and, in general, data management function allows you to define objects and customize them in real-time, including sharing data between multiple individuals, teams, and company accounts.

Catalogs and Items

One of the two basics data objects is an item. Everything is an item in OpenBOM – a single part, assembly, materials, documentation, labor, etc. Each item has a Part Number and a set of attributes (called properties).

A typical data management approach in OpenBOM is to define a robust set of catalogs to manage your data. It is worth spending a bit more time here because the usability of the system is heavily dependent on the rational data model including catalogs, types, attributes, etc. OpenBOM is flexible and allows you to define all these basic elements.

Product Structure and Bill of Materials

Once you’ve defined all catalogs and added some items, it is time to create some products. You do it by adding a root item to the catalog and creating a BOM for that item. Once done, you can open the BOM and start adding items. You can add sub-levels and by doing so, you will be creating other BOMs.

OpenBOM traces structure relationships (parent-child relationship) automatically derived from item and BOM part numbers used in the system. In such a way you can build a super complex product structure with an infinite number of levels.

Video

In this video, you can see basic steps and data navigation in OpenBOM, including the definition of multiple catalogs with items, featuring different sets of attributes (properties) for each item, and the creation of a Bill of Materials from Items.

Conclusion

OpenBOM is built on the flexible and robust data management foundation that allows individuals, engineering teams, and companies to manage product information in a scalable way. It includes the foundation of items (catalogs) and the capabilities to build product structures of any complexity. A flexible data model for items and catalogs is a basic of OpenBOM data management allowing you to build any product solutions.

REGISTER FOR FREE and check out how OpenBOM can help you and your team today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.