In the world of product design and manufacturing, the complexity of aligning data between Computer-Aided Design (CAD) software and Bill of Materials (BOM) management systems is a well-known challenge. At OpenBOM, we understand this complexity of CAD-BOM relationships. In this article, I will share some updates about improvements in the way OpenBOM simplifies the CAD-to-BOM alignment process. I’m super excited to share a new improvement of structure alignments in our OpenBOM add-in for SOLIDWORKS.

The Complexity of CAD-to-BOM Alignment

For engineers, designers, and manufacturers, creating a product involves multiple stages, starting with the design in CAD software like SOLIDWORKS and culminating in the assembly of physical components. Throughout this process, maintaining an accurate and synchronized BOM is crucial. However, the journey from the CAD design to a complete BOM can be quite challenging.

One of the primary issues in this process is ensuring that the BOM accurately reflects the CAD design with all options, exceptions and specific needs (configurations, purchasing assemblies, phantoms, etc).But this is not everything. Users are looking not only for listing the components but also organizing them in a way that aligns with the structure in the CAD software. Additionally, CAD files can come in various formats (e.g., PDF, STEP, DXF), and transferring data between these formats and the BOM can be time-consuming and error-prone.

To tackle these challenges, OpenBOM has developed a comprehensive solution that simplifies and streamlines the CAD-to-BOM integration process.

How OpenBOM Simplifies CAD-to-BOM Integration

Integrated Environment:

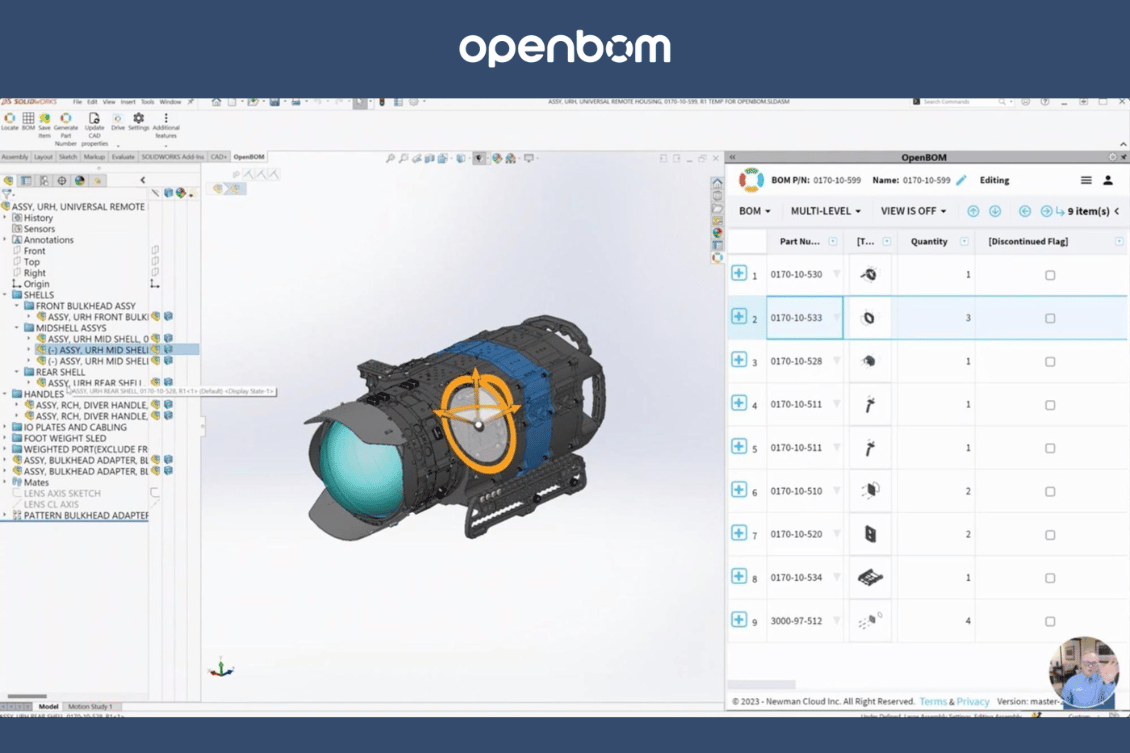

OpenBOM is seamlessly embedded into the SOLIDWORKS user interface, creating an integrated environment for users. This integration ensures that the transition from CAD design to BOM management is smooth and efficient.

Data Transfer Settings:

OpenBOM offers bi-directional mapping capabilities, allowing for the easy transfer of data between SOLIDWORKS and the BOM. Users can selectively choose attributes to transfer, ensuring that only relevant information is included in the BOM. Additionally, OpenBOM can automatically extract file types like PDF, STEP, DXF, and more, reducing the manual effort required to manage diverse CAD data.

One-Click BOM Function:

With OpenBOM, generating a BOM from your SOLIDWORKS design is as simple as a single click. This streamlines the process, saving time and reducing the likelihood of errors.

The New Improvement: Structure Alignment

One of the key insights we’ve gained from our customers is the importance of maintaining the same visual structure in the BOM as in SOLIDWORKS. Recognizing this need, OpenBOM’s flexible data modeling capabilities allow us to align the BOM with the correct order and synchronize it with the instance-based feature tree representation to create a quantity-based multi-level BOM.

Combined with our recent simultaneous visual navigation feature, this enhancement significantly improves the user experience. It ensures that the BOM not only accurately represents the CAD design but also mirrors its visual structure, making it easier for users to work with and understand.

Check out the video below:

Conclusion:

OpenBOM is committed to making CAD-to-BOM integration seamless and efficient. Our integrated environment, data transfer settings, one-click BOM function, and the latest improvement in structure alignment help streamline the process, reduce errors, and enhance the user experience.

As we continue to refine and enhance our solution, we invite you to check out our sneak peek video to see these features in action. OpenBOM is dedicated to making your CAD-to-BOM integration better with each release.

REGISTER FOR FREE and try out OpenBOM for 14 days.

Best regards,

Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.