Multi-level BOM is one of the most fundamental functions in BOM management. BOM information is always structured. To manage it is not easy and it brings lot of changes to engineers and all people in the organization. Earlier this week, we had a webinar to talk about the fundamentals of Multi-level BOM management, its role in PLM as well as other disciplines such as software quality management system, production planning. procurement, and sourcing.

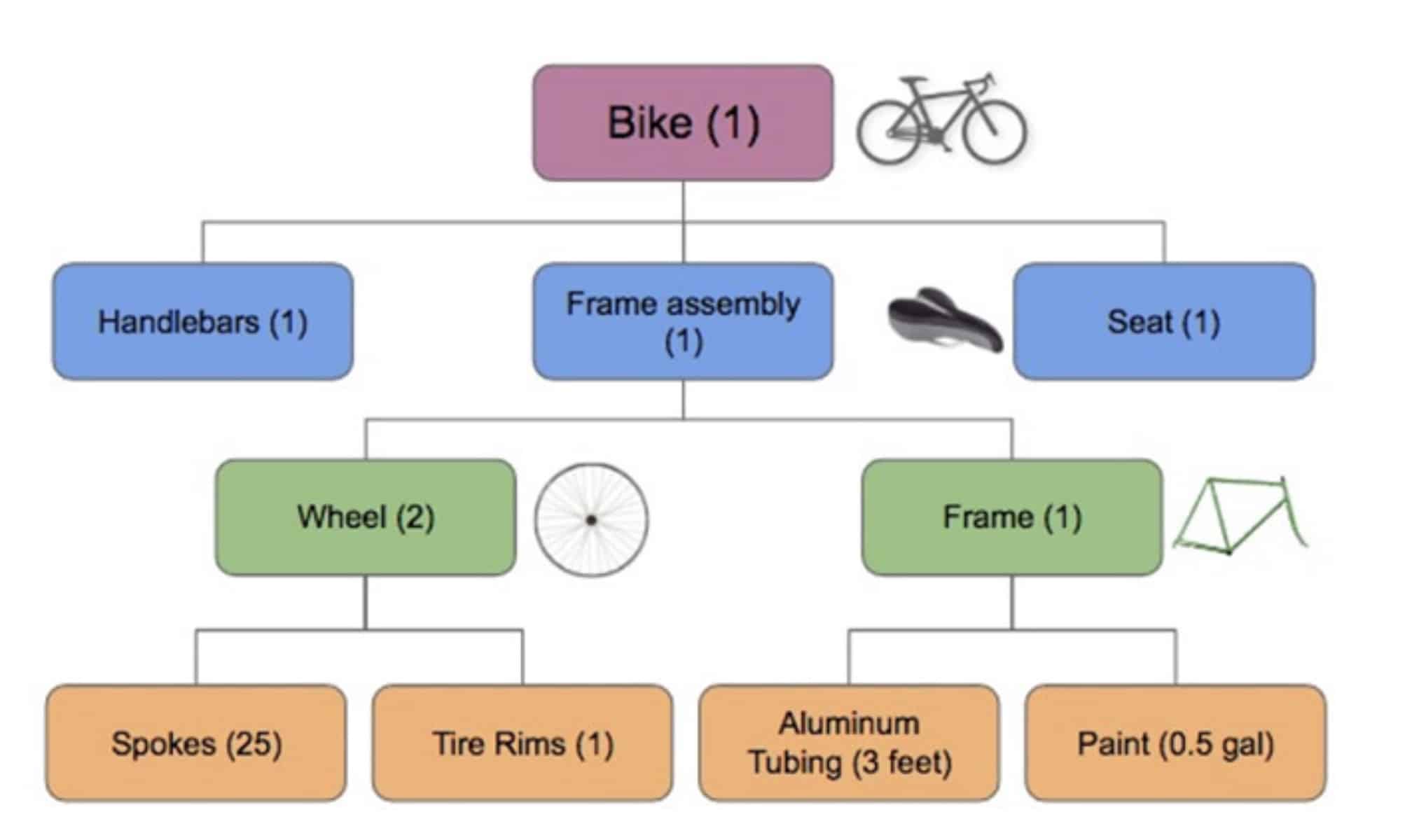

Let’s start with the definitions. Multi-Level BOM is a Bill of Materials organized into levels to show structure. Most often product structure. Single Level BOM is by definition, a Bill of Materials with no structure or levels. OpenBOM Catalog is a list of items used by your company to make your products. Often called an Inventory or an Item Master, this is a list of parts and sub-assemblies and associated information needed to put your final product together.

A multi-level BOM is created by connecting a series of individual single level BOMs together. ML BOMs can be created by reorganizing a single level into ML, Importing from Excel, and from one of the OpenBOM CAD integrations. Many OpenBOM Functions support multi-level structure such as Add Property, Formula, Assign Catalog, calculate “Cost” and other Rollups & Totals, restructure commands (Move up/down/left/right).

Here is a video from the webinar:

Also, check out the slides used during this webinar

Webinar #23 – How to create a Multi-Level BOM In OpenBOM from Oleg Shilovitsky

Conclusion

Multi-level BOM function is a fundamental of BOM management. OpenBOM is a flexible data management system allowing to creation Bill of Material with as many levels and structures. At OpenBOM we run weekly educational webinars. Check the full list of webinars here.

Check our how OpenBOM helps thousands of users and manufacturing companies to streamline data management, processes, and escape the legacy of Excel spreadsheets.

Best, Oleg @ openbom dot com.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.