Old habits die hard. BOMs and Drawings are one of the most controversial topics in engineering data management. Back in days when a drawing was the most reliable piece of information about the product (after a corkboard on the shop floor, of course :)), people put BOMs on the face of drawings. Modern digital transformation trends are bringing up the same old question again — should we put a BOM on 2D drawing on not?

Earlier this week, we had a webinar to discuss are the pros and cons of placing BOM on Drawings. Here is a short brief:

Pros of BOM on Drawing:

- Ease of use

- My MFG dept always gets all the information

- My CAD tool may do this automatically

- BOM usually matches the drawing

- BOM is automatically rev controlled with the assy drawing

- Single Document

Cons of BOM on drawing:

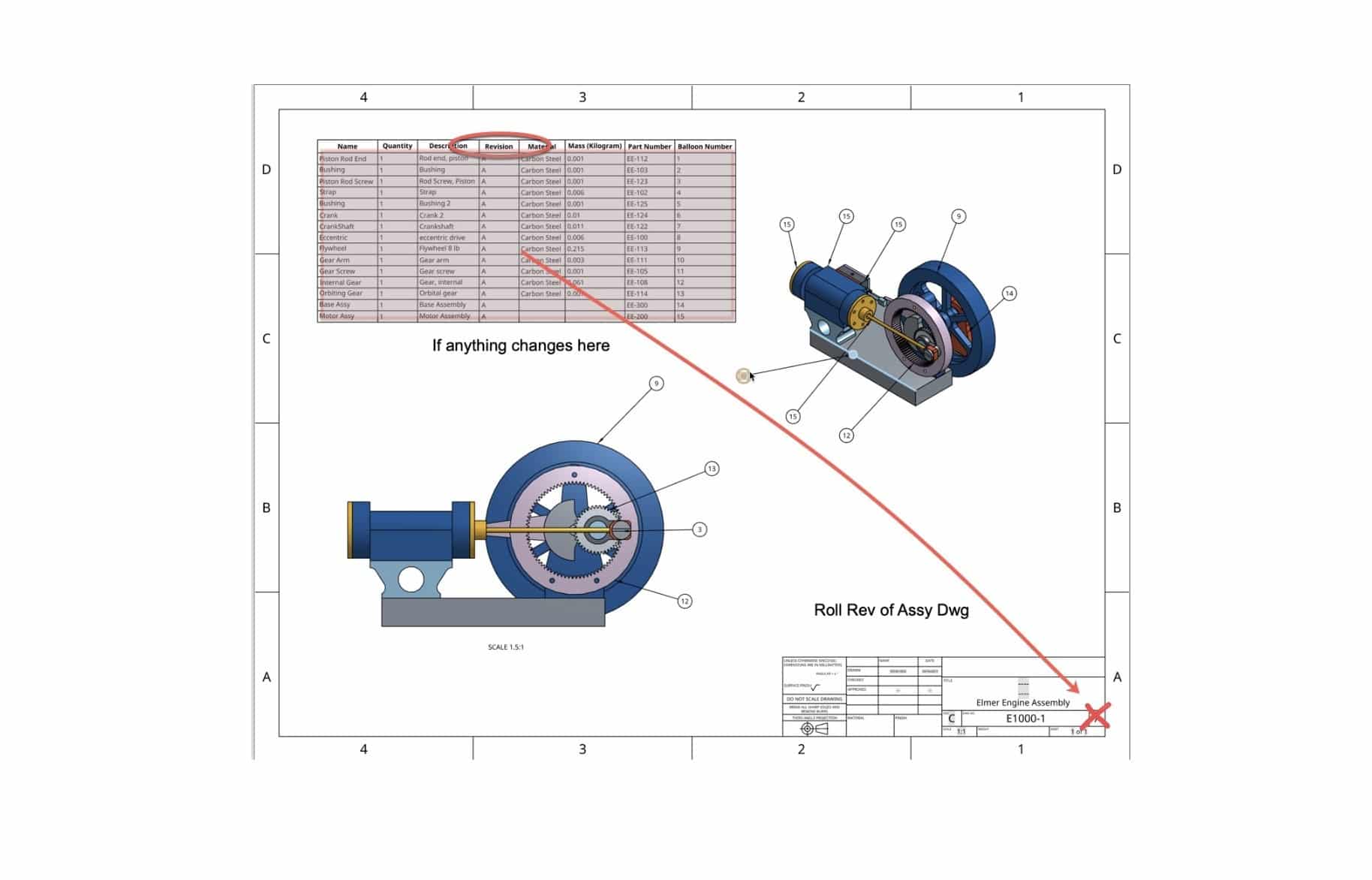

- MUST roll rev on DWG when BOM changes!

- Simple part rev forces me to update assy drawing (non-F3)

- Add grease, must roll assembly drawing revision

- Assembly drawing revision is costly

- Higher rev parts are more costly from suppliers

- No opportunity to input into other business systems, BOM on the drawing is dead (PDF) data.

- BOM is not portable, eg. must have drawn to see BOM

- No history of changes

Here is a video recording of the webinar:

And here is a slide deck of the webinar

WEBINAR: BOMs on Drawings – Still Relevant or Old School?

Conclusion.

A recent move into digital transformation brings many questions related to 2D drawings. Companies are investing in digital stories and how to transform companies by bringing new technologies. At the same time, you go to CAD systems and will see that functions of placing BOMs on the face of the drawing are still in high demand.

As a company, you need to think about how to move into a digital future. To change 2D Drawings / BOM habits might be your first step.

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out myBeyond PLM blog andPLM Book website

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.