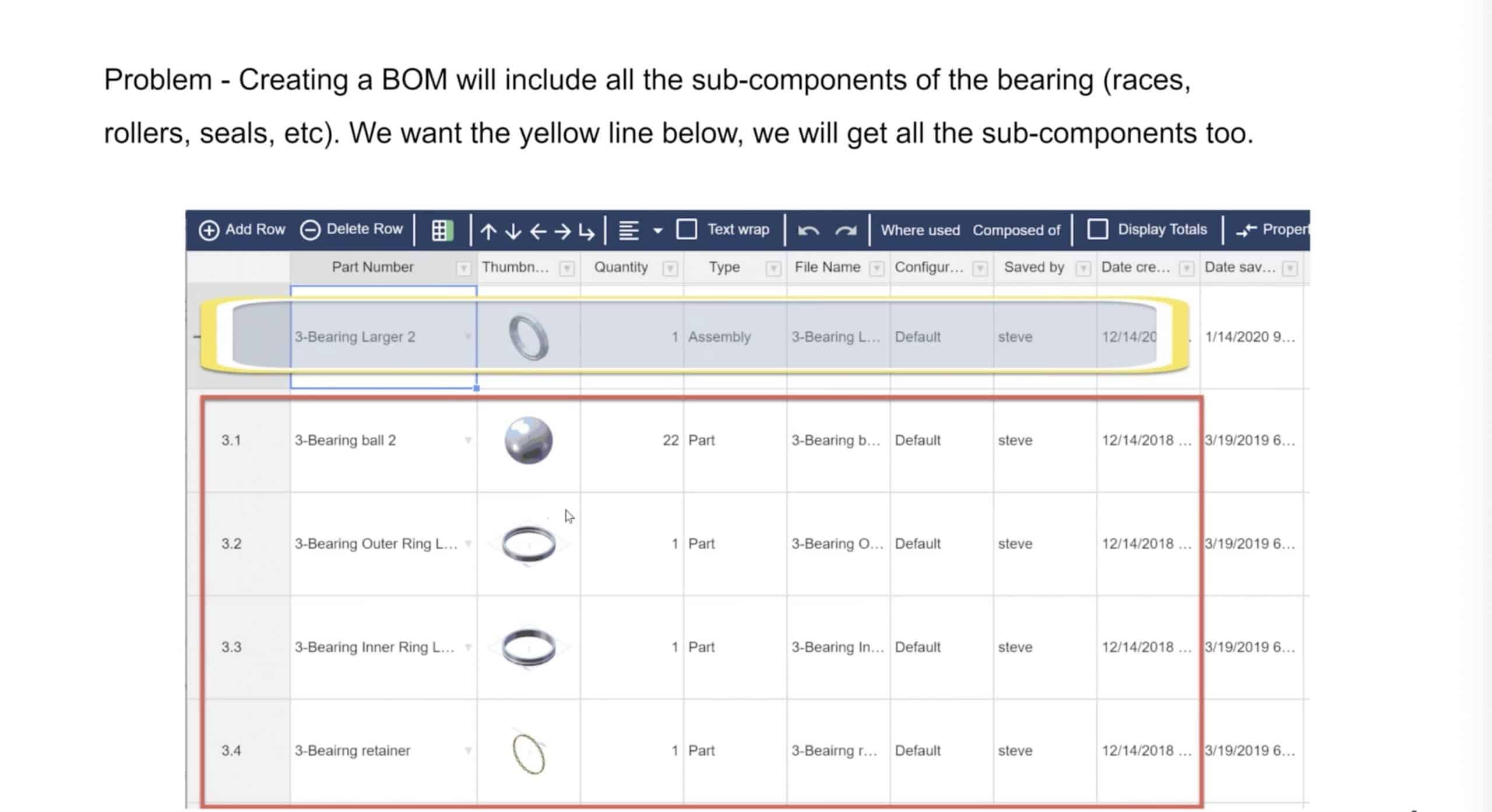

Companies buy 70% of parts of stuff used in products. Standard components, fasteners, re-usable stuff – cabinets, motors, pumps, PCB controllers, caster wheels, bearings… you name it. How to manage all this stuff in the Bill of Materials. It sounds very simple but turns out as a nightmare. The parts from a purchased assembly are mixed with other parts in your BOM and you end up with colossal data management and reporting pain.

In our BOM educational webinar earlier this week, Steve Hess, director of the user experience, shared the concepts of how you can keep purchased assemblies isolated in the BOM, so they won’t interfere with the rest of the BOM.

In a nutshell, it ends up with the ability to flag a specific assembly as purchased and make BOM ignore sub-levels.

Watch the webinar video to learn more.

And this is a slide deck.

OpenBOM CAD add-ins have intelligent features capable to recognize assembly flags to exclude sub-levels of purchased assemblies. Each CAD is slightly different. Autodesk Inventor has a component type – purchased assemblies. Solidworks has a hide/show feature. Check with us if you have questions about how to do it in a specific CAD system you have.

Conclusion.

Management of purchased assemblies can be a mess if you do it using Excels. Sometimes you need to have parts of motor assembly in and after you decided to buy it from somebody else, you don’t want them in the bill. OpenBOM features combined with out of the box CAD plug-in functions can eliminate the pain forever.

Register for OpenBOM user subscription later today

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.