As the demands of consumers change, so does the environment around them. We now live in a world where customers demand products when they want them. They are not willing to wait for a long time to get the product they desire. If the company can not provide them with the product quickly then they will likely turn elsewhere. This puts a strain on the supply chain and traditional manufacturing was unable to keep up with this instant demand. This led to the introduction of on-demand manufacturing.

This article will explain what on-demand manufacturing is as well as how it compares to traditional manufacturing.

What is On-Demand Manufacturing?

On-demand manufacturing is a manufacturing system in which parts are only made when needed and usually in small quantities. On-demand manufacturing looks at making products when there is a demand rather than the traditional manufacturing method of making products based on forecasts.

What Enabled On-Demand Manufacturing

Since the demands of the consumer have evolved, the infrastructure to provide products has needed to evolve. But, these demands are not just in manufacturing, these evolutions are in nearly every industry, such as medical, housing, transportation, food, etc…

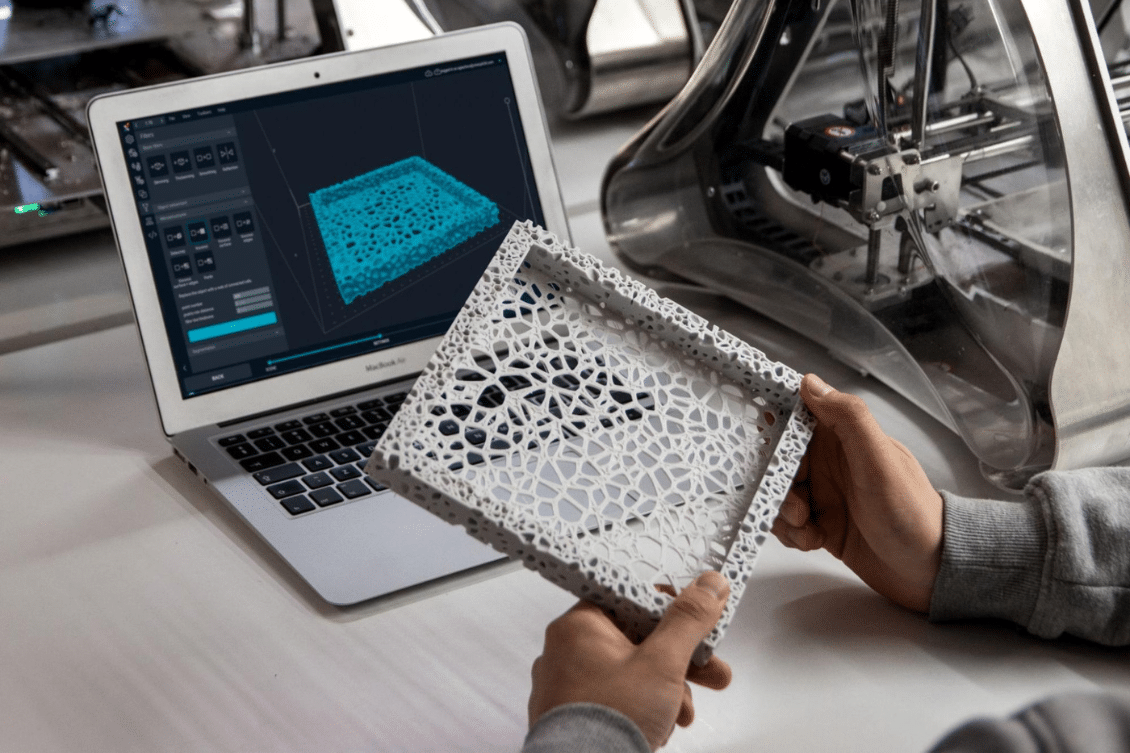

What has led to the adoption of on-demand manufacturing has been the evolution of cloud-based technology. These technologies allow manufacturers to create, control, and share their product, design, and manufacturing data. Think of how you can extract CAD data using OpenBOM’s one-click BOM function and then share this BOM with contractors.

This cloud-based technology paired with rapid prototyping and faster quoting has revolutionized on-demand manufacturing.

On-Demand Manufacturing vs Traditional Manufacturing

The main similarity between these two manufacturing systems is that they both produce products. However, the way these two systems go about making products is different. Everything from their financial model to the tools used to fabricate parts are different.

Traditional Manufacturing

In traditional manufacturing, a high-volume order is placed with the supplier. These products are usually purchased based on forecasts from the manufacturer. After these products are made, they are held in inventory until the end customer purchases a unit.

The goal of traditional manufacturing is to keep costs low. You purchase everything in large quantities so the unit price is lower – reaching economics of scale. However, certain costs do increase, such as warehousing since you need to store inventory somewhere.

Traditional Manufacturing Disadvantages

For manufacturers, one of the most challenging parts is to try to anticipate what the demands of the customers are. Based on these projects, you generate a purchase order and purchase materials in bulk. If your forecasts are wrong then it will lead to having too much inventory or not having enough products for your customers.

Here are some other drawbacks of the traditional manufacturing system.

- Higher MOQs that smaller manufacturers have difficulties absorbing.

- The lead times are long.

- Large initial investments in purchasing production tools, molds, and jigs.

On-Demand Manufacturing

On-demand manufacturing on the other hand is looked at to meet the needs of the consumer rather than relying on forecasts. There are several advantages to this new manufacturing system.

On-Demand Manufacturing Advantages

On-demand manufacturing is used to meet the instant demands of customers. On-demand manufacturing is also looked at during the product development phase to quickly make prototypes that can be used for testing and market testing. Here are some other advantages of on-demand manufacturing.

- Time Efficiency: The processes of on-demand manufacturing can produce products faster than the traditional manufacturing system.

- Quick Quotes: On-demand manufacturing provides manufacturers with an instant quote of how much a part will cost

- Boosts Cash Flow: On-demand manufacturing eliminates the need for molds that are necessary for traditional manufacturing. You also don’t have warehousing and inventory costs with on-demand manufacturing.

- Market Validation: Since you are able to quickly produce parts, you can test and validate the parts with the market.

- Speed to Market: On-demand manufacturing enables product development teams to quickly go from CAD to market.

On-Demand Manufacturing Drawbacks

While on-demand manufacturing is creating a lot of opportunities, there are still some drawbacks to this manufacturing system.

- Mass Production: On-demand manufacturing is ideal for low production runs but fails to deliver products in large quantities

- Controlling the Supply Chain: A manufacturer using on-demand manufacturing has little visibility into the supply chain.

- Costs: Scaling on-demand manufacturing at scale is not as cost-effective as the traditional method.

Steps you can take today

Manufacturers looking to implement on-demand manufacturing first need to take a few preliminary steps to make sure they can proceed smoothly. The major step is understanding how to manage their engineering and design data. If your data is a mess then don’t expect the output of on-demand manufacturing to be what you expect it to be. This is where OpenBOM comes in.

OpenBOM is a cloud-based PDM & PLM platform to manage your engineering and manufacturing data. Companies from startups to Fortune 500’s use OpenBOM to create a centralized database to bring in, store and manage their manufacturing data. With this infrastructure, users also use OpenBOM to streamline both their change management and PO processes.

If you need to improve the way you manage your data and processes, contact us today for a free consultation.

Regards,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.