I’m excited to introduce the latest enhancements in OpenBOM, which bring better control, usability, and integration to your engineering and manufacturing processes.

The improvements include user experience, graph navigation, governance, PDM features, and improvements in CAD integrations.

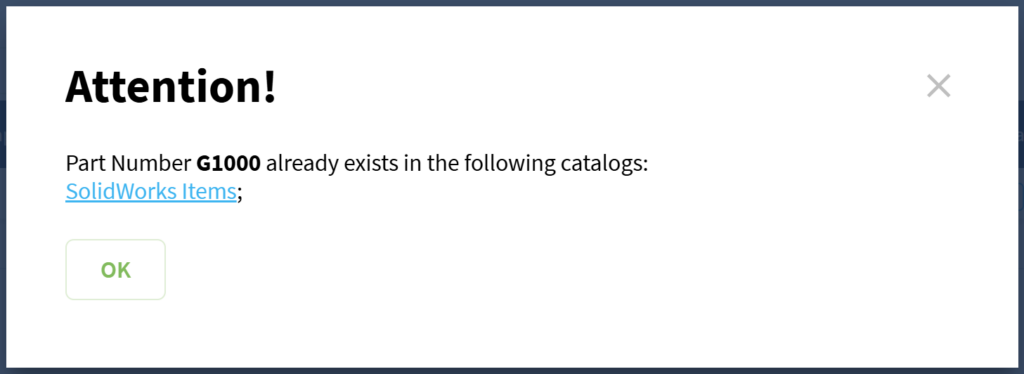

On the data management side, we improve how OpenBOM manages the uniqueness of Part Numbers and control mistakes related to the introduction of duplicated Part Numbers. Part Number Duplicate Validation mechanism was improved and now controls global Part Number duplication across all catalogs. More on the side of the Part Numbers setup will come, introducing cross-catalog Part Numbering systems in coming releases.

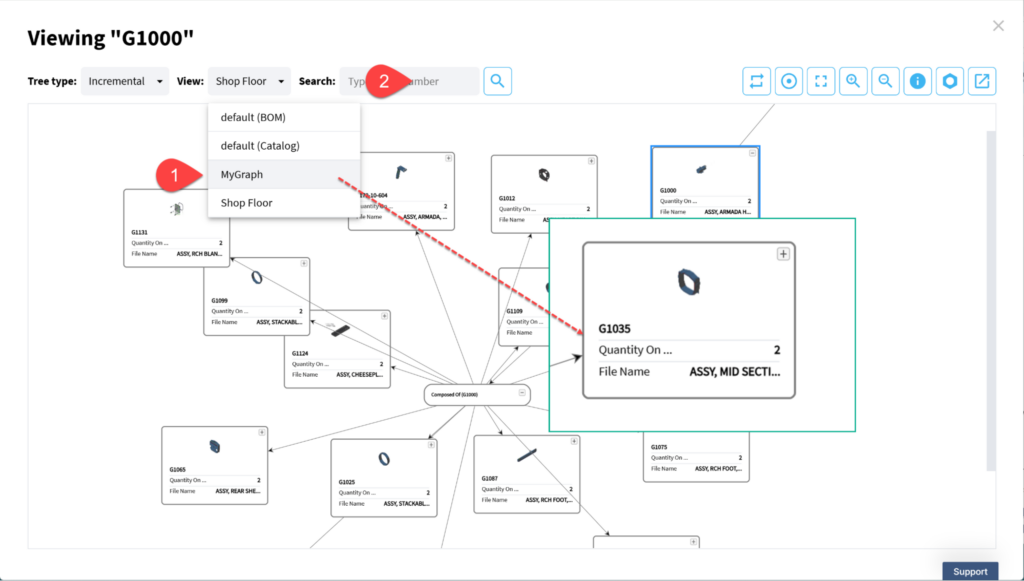

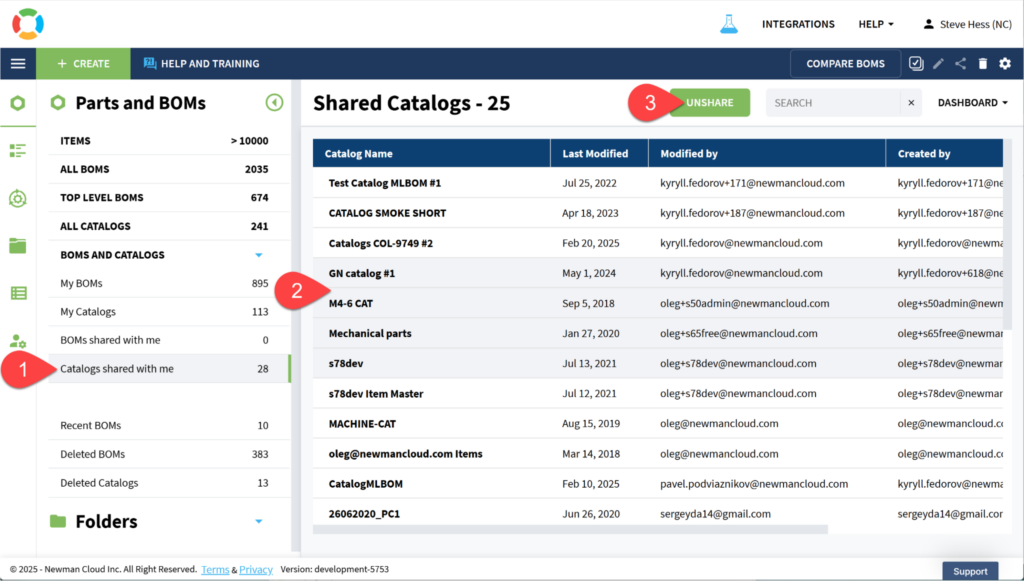

The Graph View has been enhanced with improved view configurations and search, making it easier to navigate complex product structures. We’ve also added more flexibility to collaboration with the ability to unshare yourself from BOMs and catalogs when needed.

On the user interface front, we’ve introduced resizable panels to improve screen space utilization, along with better sorting and filtering options to help you find information faster.

We’re also rolling out improvements in Design Projects Workspace Management, including the introduction of a multi-project sync and special report and the ability to lock or unlock entire projects for better control over data access.

For CAD add-ins, we’ve made significant enhancements to our integrations for PTC Onshape and Dassault Systemes Solidworks. One of the key enhancements is the introduction of the integrated Workspace Manager, which is, for the first time, available for Solidworks and many other features, such as direct link to designs and introduced better part number generation.

These updates continue our mission to make OpenBOM a powerful, flexible, and user-friendly solution for managing product data. As always, we appreciate your feedback and look forward to hearing how these improvements help your workflow!

Now, let’s speak about all these features in more detail.

Unique Part Number Control

OpenBOM continues to improve data validation with this release. A new Part Number duplication control will prevent adding duplicated Part Number by free typing or generating duplications. After working with multiple customers we identified that we need to tighten the control and provide a more restrictive mechanism for introducing duplications as a result of bad data coming from multiple sources (eg. Excel or CAD). As a first step, OpenBOM will prevent duplicated Part Number typing and introduce duplicated Part Numbers entered via CAD add-ins.

This step continues our efforts to ensure you create consistent, reliable Item information in OpenBOM.

Later in the coming releases, we are going to introduce a global Part Number setup allowing to manage cross-catalog Part Number allocation and also automatic generation of Part Numbers when importing from Excel and other spreadsheets.

“Duplicate Item” (Copy) behavior

In accordance with the behavior described above, the ‘Duplicate Item” behavior has changed slightly to prevent the creation of duplicate Part Numbers. The copy function will create a copy of the data but will modify the Part Number with a random number appended. So just edit the new Item’s Part Number to be the desired value.

Graph Navigator- User Defined View Support and Search

This release brings two very important additions to the Graph Navigation – Support for Views and Search. Use your team views in the graph navigation. Simply select the user-defined view in the view selector. Also, a full search is in the graph navigator.

Watch the video

Unshare Command

The un-share mechanism allows you to remove data that is shared with you. Has someone shared a catalog with you that perhaps has duplicate part numbers? Or has content you no longer need or want access to? This release introduces the “Unshare” command. A fast and easy way to quickly unshare yourself from any BOM or Catalog that has been shared with you, even if it was shared with you as Read Only!

Select any BOMs or Catalogs from the “Shared with Me” dashboard, and easily Unshare.

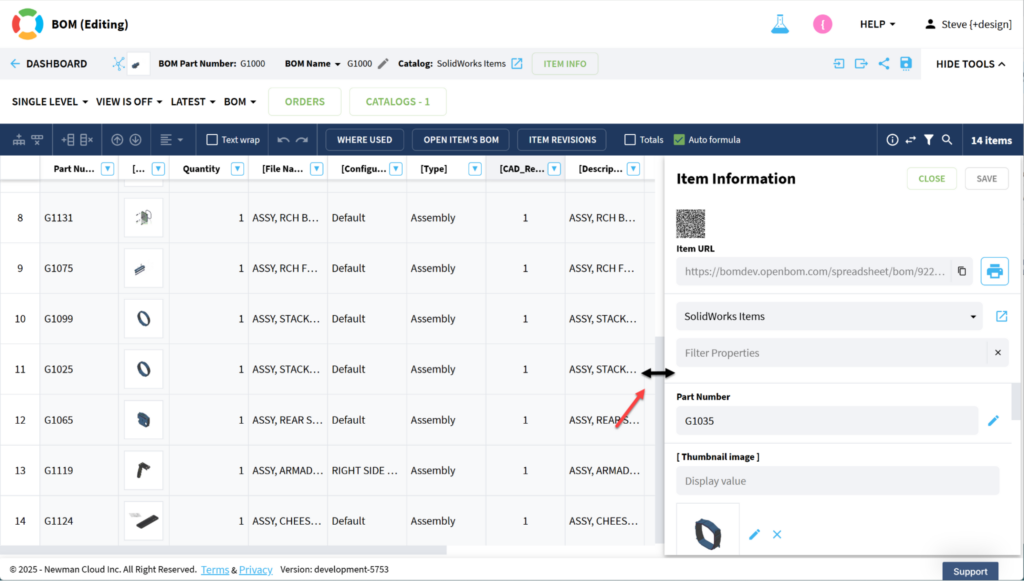

Resizable panels in Data Objects

A very nice user experience improvement allows you to adjust the width of the side information panels – they can now be resized.

Sort & Filter Improvements

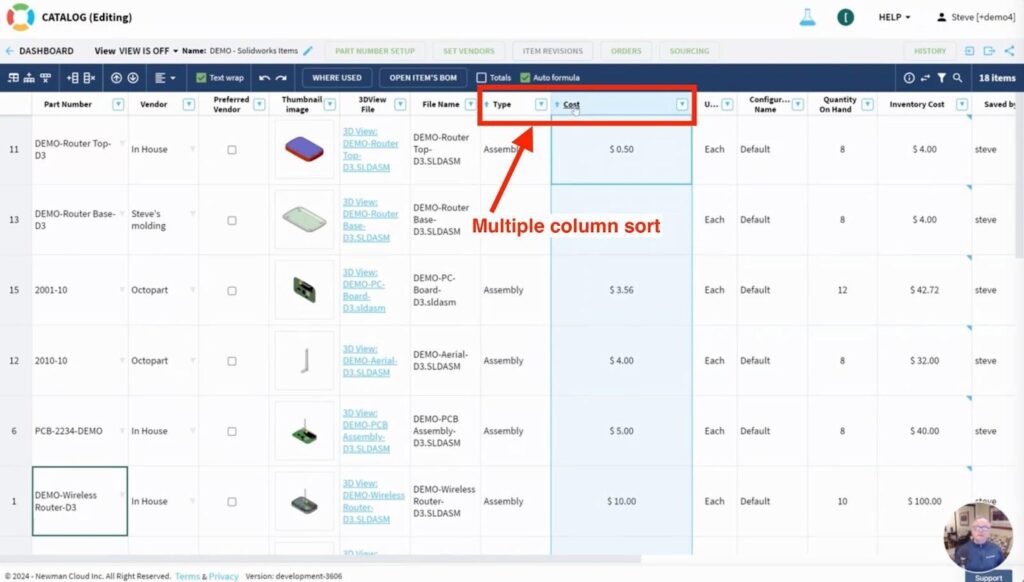

Efficiently navigating through extensive datasets is integral for professionals handling BOMs and related data objects. When you navigate through the tables of data (eg. catalogs), having intuitive sorting and filtering mechanisms is critical. Two improvements were prioritized in our last development sprint – sort by multiple columns and advanced filter conditions.

Sort: Introducing Multiple Column Sort

One of the great new features of the coming update is the introduction of multiple-column sorting. With this enhancement, users now have the ability to sort data based on multiple column values simultaneously. This empowers users to arrange data in a manner that aligns precisely with their specific requirements, enhancing overall usability and efficiency.

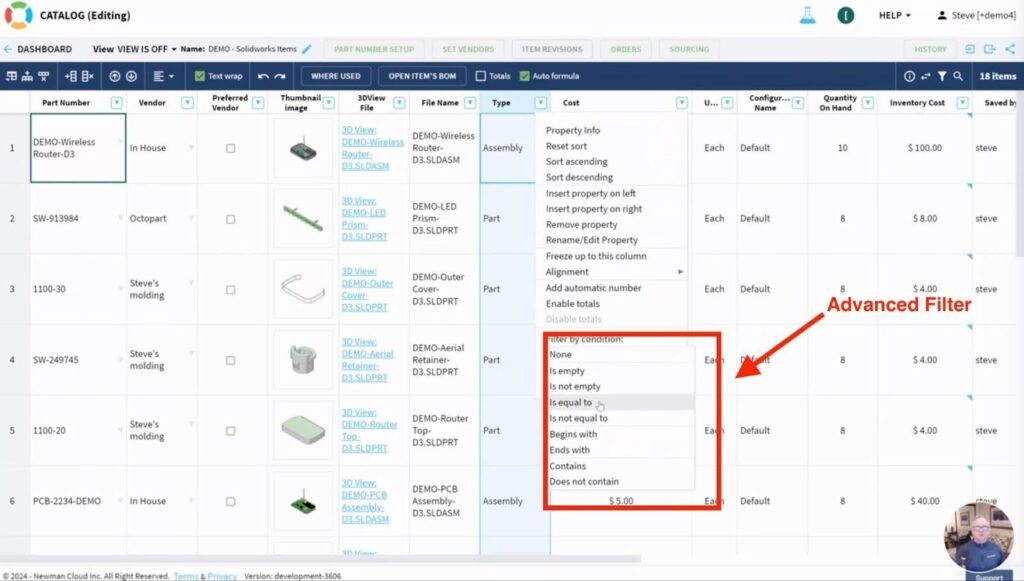

Filter: Advanced Filtering Capabilities

In addition to enhanced sorting, we’re also introducing a new mechanism for applying advanced filtering capabilities. Users can now employ a variety of filter options, such as empty fields, greater than, less than, and many others. This level of granularity provides users with greater control over refining their data views, ensuring that they can focus on the information that matters most to them.

Watch the video of the new features:

OpenBOM Design and Workspace Manager

We continue to improve PDM capabilities and features of Design Projects. In this release, we have focused on improvements of Workspace Management and synchronization capabilities.

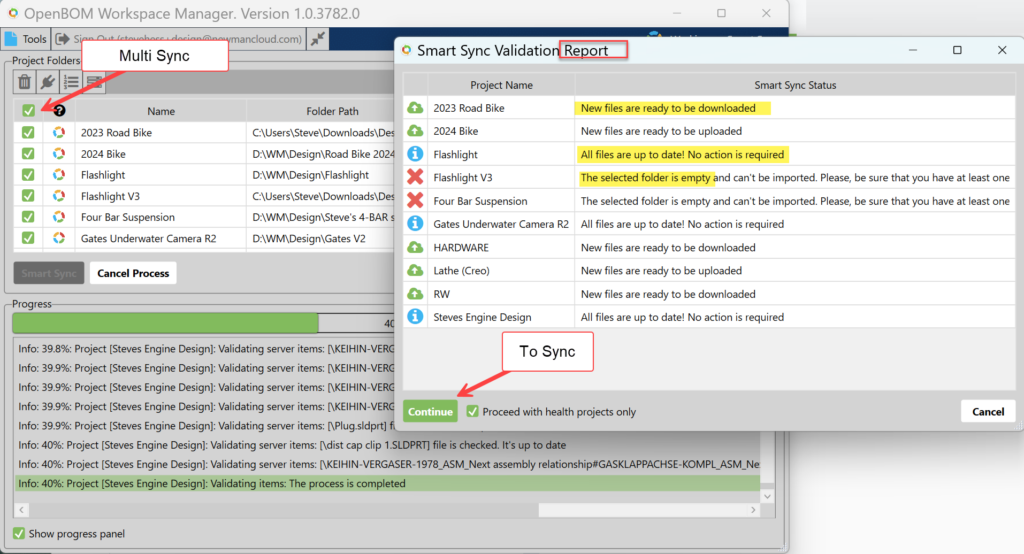

Multi-Project Before Synchronization Report

The report now provides individual project details and sync status before the SmartSync operation is executed. This is very useful when working on multiple projects or when a single CAD design actually references multiple projects, possibly when you have hardware in one project and the design in another.

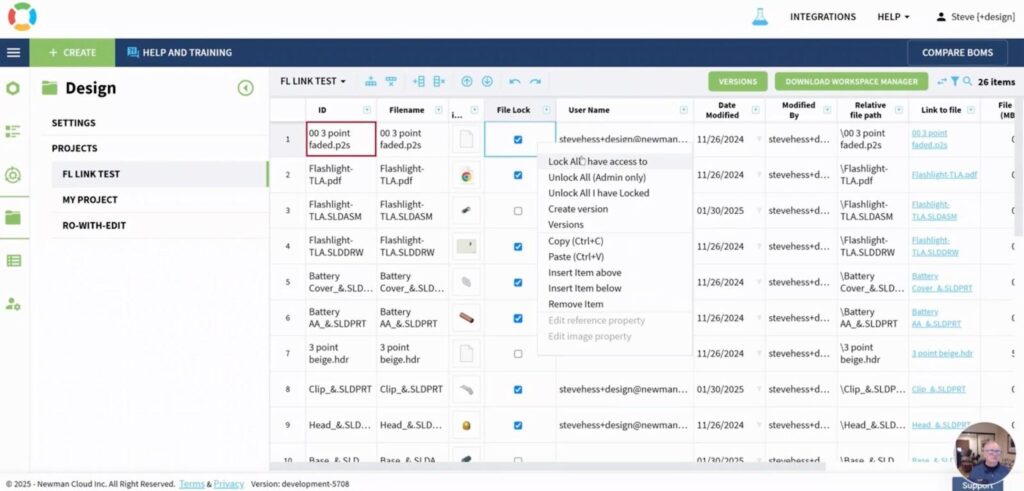

New Design Projects Lock Functions

When you manage CAD files using Design Project, the lock mechanism allows you to check-out/in files to prevent other people from editing files at the same time. The original lock supported individual file locking. However, the feedback from customers allowed us to design a better way to lock files to minimise clicks when working with multiple files.

The new options simplify workflows, reduce unnecessary clicks, and give both users and admins greater flexibility in managing file access.

The Four New Lock/Unlock Enhancements. The menu of file control in Design Projects now has a few additional lock / unlock options. Here are descriptions of the enhancements.

1️⃣ Lock All I Have Access To

Instead of locking files one by one, you can now lock all files you have access to in one action. This is perfect for when you need to work on multiple files and want to ensure no one else makes changes while you do.

2️⃣ Unlock All I Have Access To

When you’re done with your edits, this function allows you to unlock all your locked files at once, saving you from manually unlocking each file. A simple, time-saving enhancement!

3️⃣ Unlock All (Admin Only)

Admins now have the ability to unlock all files across a project in a single click. This is particularly useful when managing large teams or resolving locked files left unattended.

4️⃣ Unlock Someone Else (Admin Only)

Admins can now unlock files locked by other users. Whether someone forgets to release a file before leaving for the day or locks are preventing progress, this option gives admins the power to maintain project flow.

Watch the video of the feature

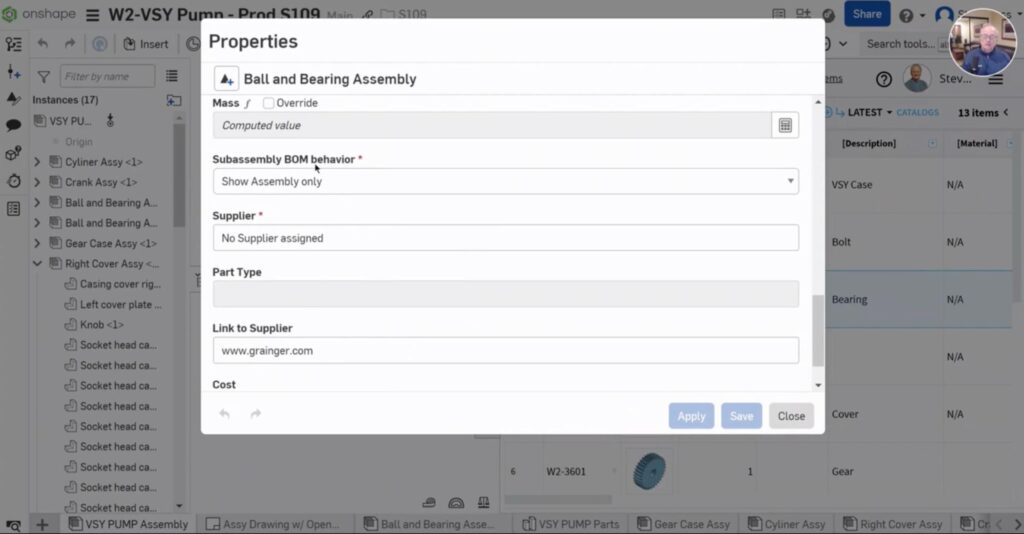

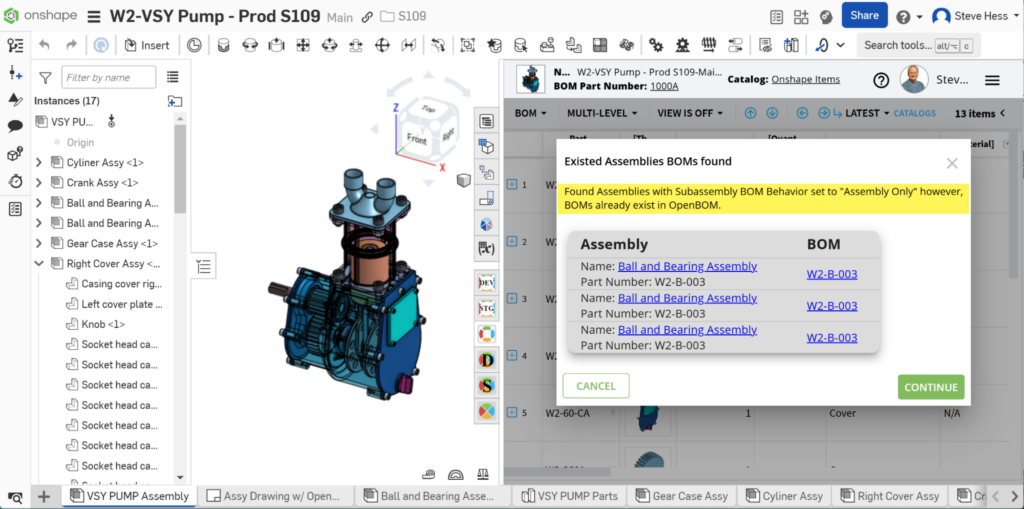

OpenBOM for PTC Onshape

A new feature to warn behavior is set to assembly and a BOM already exists is introduced.

The Onshape Assembly Behavior setting is very useful when modeling assemblies that will be purchased as a single line item. We often refer to this as the Purchased Assembly option.

With this release, we take it a step further by notifying you when the behavior is set to an assembly and a BOM already exists in OpenBOM. The purpose of the function is to alert about existing assemblies (BOM) that in fact, need to be deleted since you introduced a purchased assembly setting.

For example, you built the first 10 enclosure doors in-house. Then, as you scale, you send them out to a supplier who delivers them as a complete door. You are now buying the assembly as a line item and do not need a sub-assembly BOM.

Watch the video:

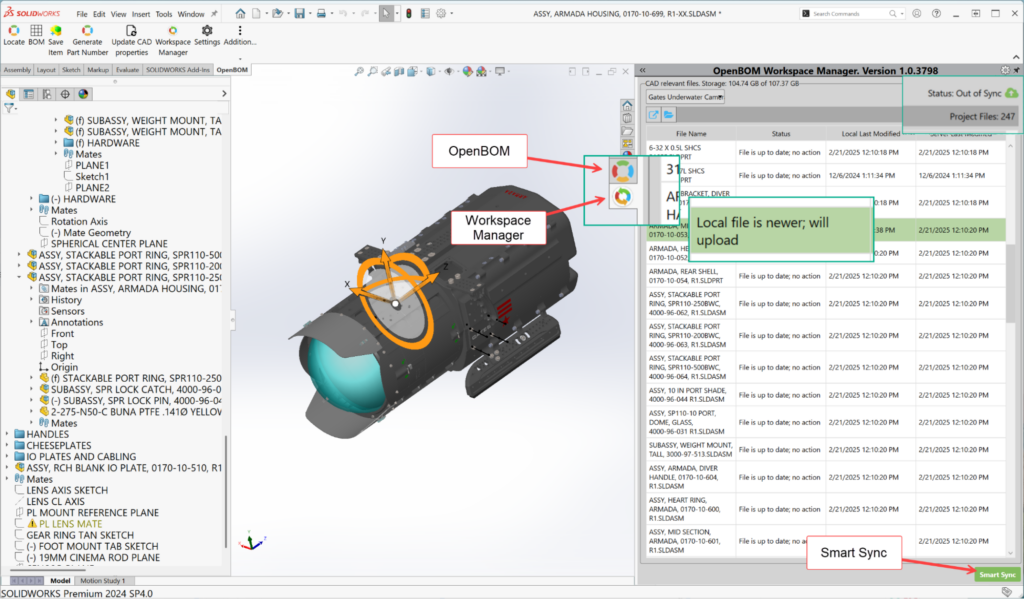

OpenBOM Add-in for Dassault Systemes SOLIDWORKS

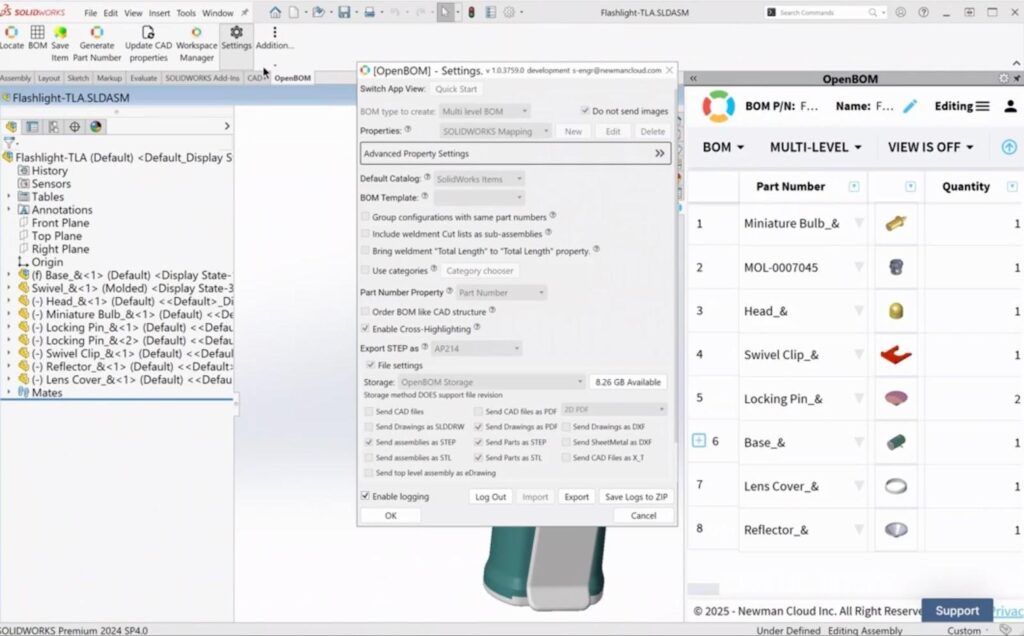

We are enhancing the SolidWorks / OpenBOM Experience with Workspace Manager. The new Workspace Manager (WM) inside the SolidWorks Flyout provides a more integrated and efficient way for engineers to manage their design data.

With Workspace Manager and Smart Sync, OpenBOM automatically identifies the Design Project and local file locations, giving users a clear and structured view of their CAD files. It highlights which files are up to date, need syncing, or are new and not yet assigned to a project—eliminating manual tracking and reducing errors.

By providing real-time visibility and context-aware file management, Workspace Manager ensures a more efficient and organized workflow inside SolidWorks, helping engineers focus on design rather than file administration.

Watch the video demonstrating the feature.

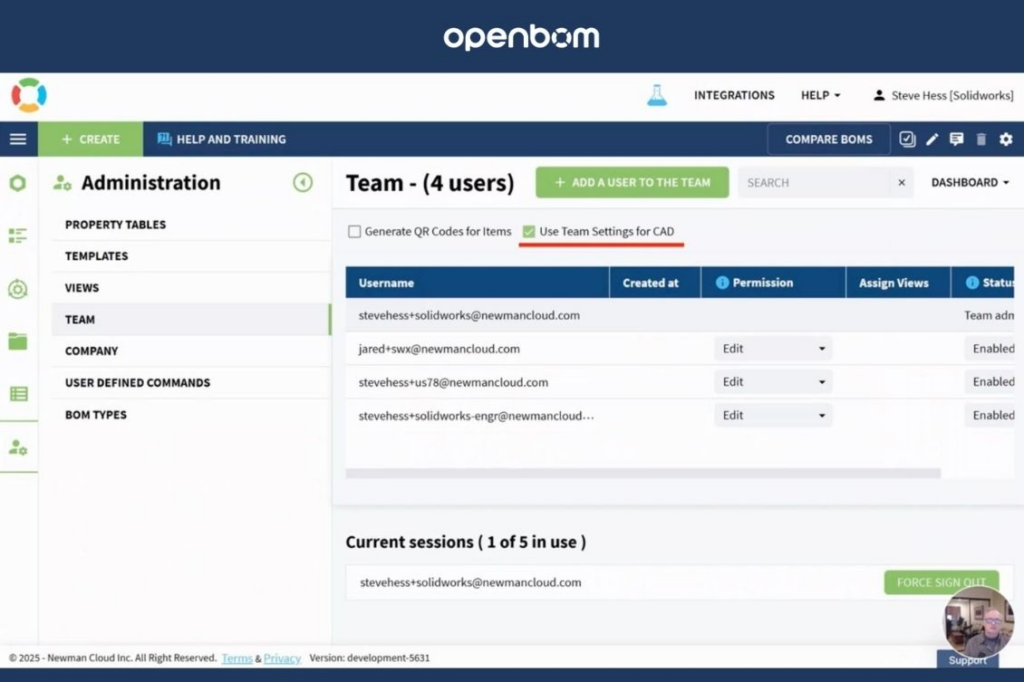

Team Settings for OpenBOM Add-in in Dassault Systems SolidWorks

Managing CAD integrations across teams can be challenging, especially when individual users configure their settings differently. To simplify this process and enhance governance, OpenBOM is introducing Team Settings for CAD Add-ins—a centralized way for admins to create and enforce uniform settings across all users.

With this new capability, OpenBOM admins can now:

- Set up an OpenBOM CAD add-in.

- Configure the desired settings.

- Select [✓] Use Admin CAD Add-in Settings in the dashboard.

Once enabled, all users within the team will automatically inherit these settings, and their individual configurations within the CAD add-in will be locked. This ensures consistency across the entire company.

Key benefits of the new Team settings:

✅ Simplifies Administration – Admins can configure the settings once and apply them to all users, reducing setup complexity.

✅ Ensures Consistency – No more mismatched configurations between different users—everyone operates with the same settings.

✅ Saves Time – Teams can get up and running quickly without wasting time on setup and troubleshooting.

Watch the video

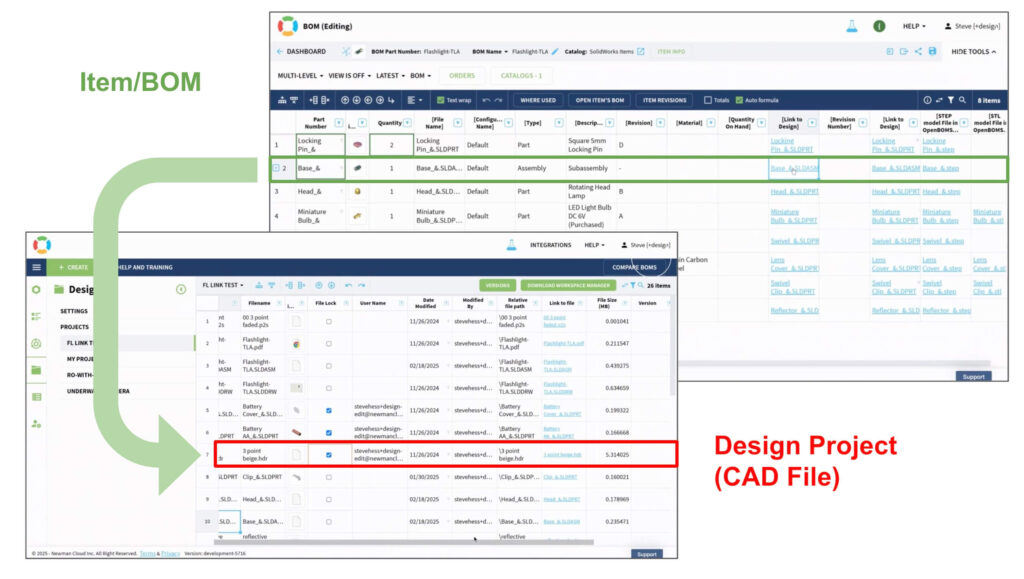

Connected Items and Design Projects

One of the persistent challenges in product lifecycle management is keeping design data connected to BOMs. Traditionally, “as-designed” and “as-engineered” data exist in separate silos, making it difficult to maintain traceability.

With OpenBOM’s new Automatic Connected Items feature, when you create a BOM from a SolidWorks assembly, OpenBOM now automatically links BOM items to their respective design files in Design Projects.

What This Means for You:

- The BOM and design files remain connected, ensuring easy access to critical information.

- Engineers can quickly trace where an item originated within the Design Project.

- It improves collaboration between design and manufacturing teams, reducing errors and miscommunication.

This new functionality closes the loop between design and engineering by ensuring that product data remains consistent and easily accessible.

Watch the video of the new features:

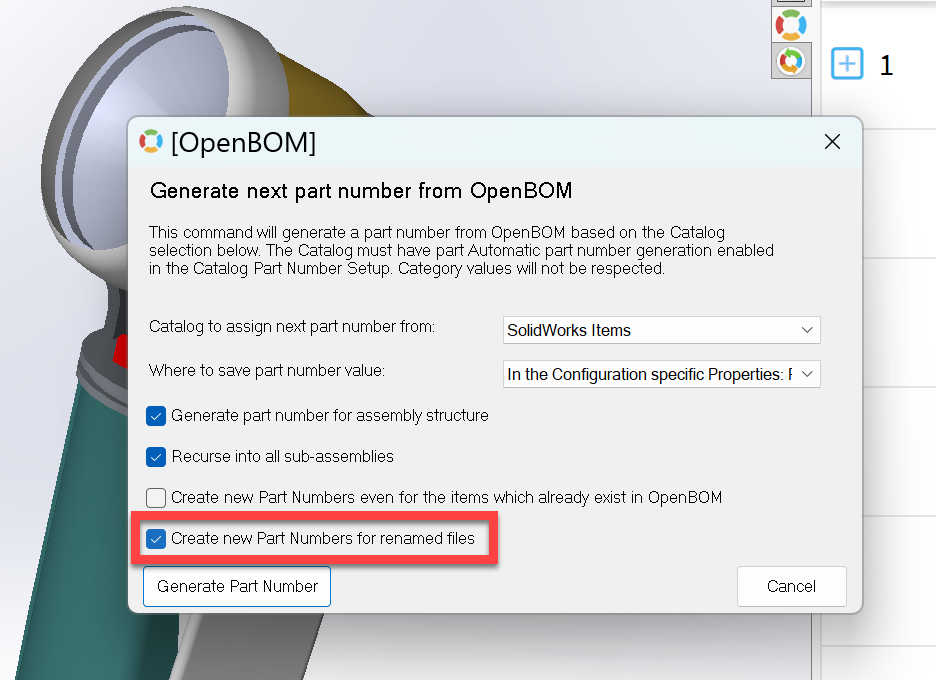

Generate Part Numbers Improvements in SolidWorks.

Do you ever use the PackNGo feature to create a copy of an assembly that you will be bringing back as a “make from”? In other words, re-using the Solidworks assembly but making some slight changes.

New OpenBOM Get Part Number function can now assist you in assigning new part numbers to those parts that you will be copying.

Here is how:

- Open an existing SolidWorks assembly for which you have already saved an OpenBOM Bill of Materials.

- Remember, these files have an existing Part Number property with the correct value.

- Use the Pack and Go command to make a copy. Be sure to add a file prefix or suffix to create a ZIP file with unique filenames.

- Move the ZIP file to a new OpenBOM Design Project folder (or any location where you store your data).

- Unzip the new files.

- Now, the new (unique) files have one issue—the Part Number property still contains the part number from the original file (the one you copied from).

- Open the top-level assembly in SolidWorks.

- Use the OpenBOM Get Part Number command and select the following:

- Click Generate Part Number

For each file in the assembly, OpenBOM will check the Part Number property and compare it to your team’s OpenBOM data. If the part number exists but the file is different, OpenBOM will generate a new Part Number. Effectively, this feature will allow you to assign new Part Numbers to the new files.

In summary, the new Part Number generation feature enhances Solidworks Pack-n-Go by allowing you to duplicate designs for new projects and generate BOMs for new assemblies efficiently. This powerful feature is particularly useful when using Solidworks Pack-n-Go to execute a “make from” operation on existing SolidWorks data.

Summary

This month, OpenBOM introduces enhancements across data management, user experience, and CAD integrations, reinforcing its role as a comprehensive digital thread solution. An improvement is the strengthened control over Part Number uniqueness, preventing duplication errors from manual entry and CAD imports. Additionally, the platform introduces a global Part Number setup for better cross-catalog management and automatic generation from spreadsheets.

The Graph Navigator now supports user-defined views and search, simplifying navigation through complex product structures. The introduction of the “Unshare” command also enhances collaboration control, allowing users to remove themselves from unnecessary shared BOMs and catalogs.

User experience improvements include resizable panels for better screen space utilization and advanced sorting and filtering options, such as multi-column sorting and condition-based filters. In Design Projects, OpenBOM now supports multi-project synchronization reports, giving users a clear overview before SmartSync operations. Enhanced file-locking mechanisms provide administrators with new tools to manage access efficiently, including bulk lock/unlock options and the ability to override locks when necessary. These updates streamline PDM workflows and improve data governance across teams.

For CAD users, OpenBOM expands its integrations with platforms like PTC Onshape and Dassault SolidWorks. The new Workspace Manager for SolidWorks provides real-time visibility into design files, reducing errors and improving synchronization. OpenBOM now automatically connects BOM items with their respective design files in Design Projects, ensuring traceability between design and manufacturing data. Enhanced Team Settings for SolidWorks also allow admins to enforce uniform CAD add-in configurations across teams. Lastly, OpenBOM introduces a smarter Part Number generation tool, helping users efficiently manage copied assemblies in SolidWorks Pack-n-Go. These updates continue OpenBOM’s commitment to providing a modern, cloud-based PDM and PLM experience.

Check what OpenBOM can do for you – REGISTER FOR FREE.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.