Developing a new product is both exciting and challenging. As a startup, you face a range of obstacles, including limited resources, a tight budget, a lack of market presence, and more. One crucial decision you will need to make is whether or not you manufacture your product in-house or if you outsource to a contract manufacturer (CM).

Partnering with a CM can have several benefits that allow you to focus on your core competencies. However, the decision to work with a CM is not always straightforward.

In this blog post, we will explore key considerations startups should make when deciding whether to partner with a CM. We will also examine the advantages and disadvantages of working with a CM and offer practical advice to help you make an informed decision that aligns with your business goals.

Main Advantage – Speed to Market

At a startup, you usually lack many resources. One of these resources will be money. Early startups are forced to fundraise in order to fund development. However, ultimately, what these startups are looking to accomplish is to sell their product to generate revenue. In order to do this, they need to quickly and efficiently launch their product.

One of the main advantages of working with a supplier is to improve your speed to market. A CM can help with this in multiple ways.

Skill Sets

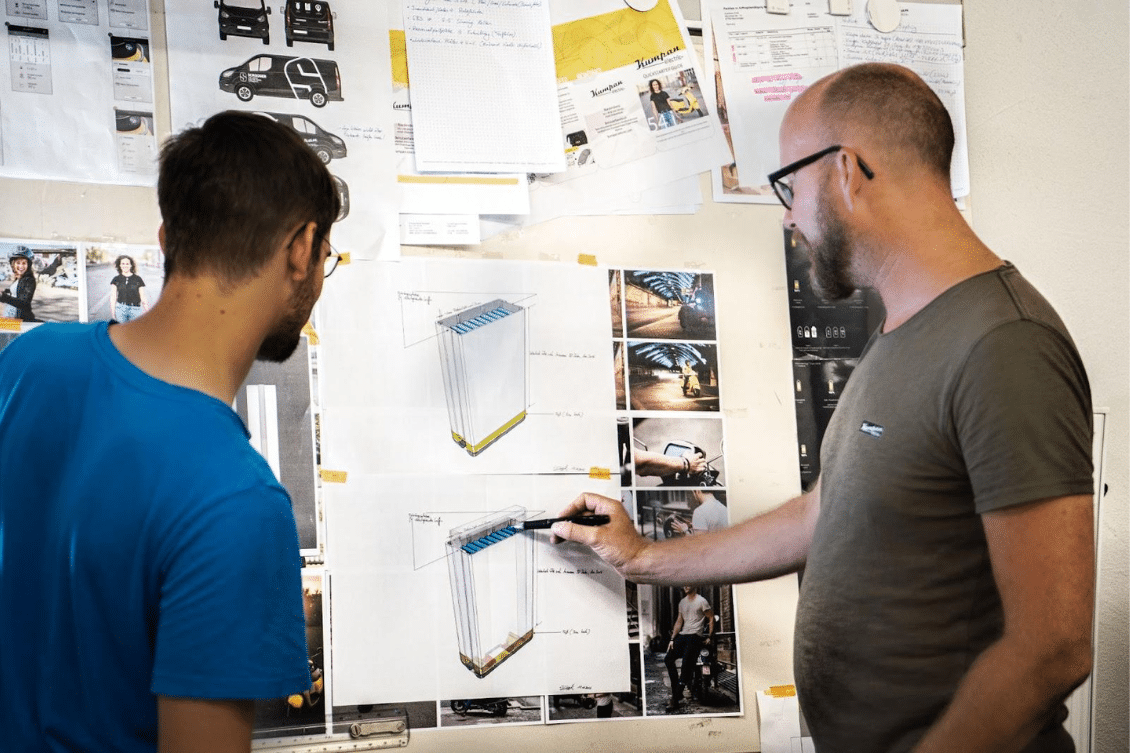

When you are evaluating a CM, you will need to look for a potential company that can complement you. This means a company that can provide support where you are not strong. These skill sets can range from engineers with a specific specialization to operators, weldors, etc…

Design for Manufacturing (DFM)

As you start to navigate through the development step and you start preparing for production, you will need to optimize your product for production. The startup will often look to the CM to provide them with support in design for manufacturing (DFM).

The logic to outsourcing DFM to your CM is that they have the production lines, they understand the materials, and understand the processes, and tools needed in order to build your product. With this knowledge, they are able to transition your product from the prototype stage to production.

Scaleability

The cost to scale up manufacturing operations is a large expense. There are a lot of equipment, tools, space, and more that are necessary to scale up production operations. The CM you choose should have this for you. If not then are they willing to invest in their operations in order to sustain your growth?

CMs can also provide startups with the flexibility to scale up and scale down production quickly depending on market demand. If you have your own production facility then you’ll need to manage the labor force.

Supplier Relationships

One time-consuming event is choosing a supplier or CM that you will use for production. You need to spend hours communicating with the supplier and vetting them. Finally, after weeks or months of talking to a few suppliers, you land the one you want to choose. Now imagine doing that for every single sub-supplier.

CMs have established relationships with suppliers which allows them to source materials quickly and efficiently. Having these relationships will help startups avoid delays and production disruptions, ensuring that their products are manufactured and delivered on time.

Timing is Everything

The product development journey is long. There is no specific time for when you reach out to a CM for a partnership. Depending on your product, the complexity, and other factors, there are specific times when you should be engaging with your supplier. Here are a few times when you should partner with your supplier

After Proof of Concept (PoC)

If you do not have a PoC then it’s safe to say it’s too early to contact your CM. The CM becomes valuable when you have a product that people want to buy.

Post Prototype

The best place to start communicating with a supplier is when you have a prototype that you are proud of. The prototype does not have to be the final prototype but something you can physically show for marketing or product reasons.

Have a Business Case

Before you start to partner with a CM, you will need to have a business plan. The reason for this is that during the evaluation process, your CM will request some info about your company. They will most likely ask for a business plan because they would like to see what they are working on and will have buyers in the future. They will also like to know the annual forecasts which of course are difficult to develop with historical sales figures but nonetheless, still important in the eyes of a CM.

Overall, there is no perfect time to contact a supplier to begin a partnership. It’s always best to contact them early to start building that relationship. However, they will not be able to start providing value until you have a prototype and a business case for your product.

How to Start Your Journey Today?

If you are a startup and looking to gain a competitive advantage by working with a contract manufacturer then you should also start your digital transformation journey. Digital transformation will keep all of your product data together and manage your revisions and create an ECR/ECO process. Your solution is a centralized platform that connects your team, contractors, and suppliers.

OpenBOM is a cloud-based PDM & PLM platform to manage your engineering and manufacturing data. Companies from startups to Fortune 500’s use OpenBOM to create a centralized database to bring in, store and manage their manufacturing data. With this infrastructure, users also use OpenBOM to streamline both their change management and PO processes.

If you need to improve the way you manage your data and processes, share data instantly, or to collaborate with contractors and suppliers. contact us today for a free consultation.

Regards,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.