During the life of your product, you might need to change your contract manufacturer (CM) or suppliers. This might be because your supplier went out of business or for other operational reasons. Regardless, of the reason, you will need to plan a transition period so you do not negatively affect your output.

This post will go into more detail on why manufacturers want to change suppliers and also how they can change suppliers without affecting their production output.

Why Manufacturers Change Suppliers

There are multiple reasons why manufacturers would like to change suppliers. Most of the reasons are that they affect your bottom line. Whether this is their production costs, quality, lead time, or inability to scale, all of these hinder your growth. The following reasons are the most common why manufacturers want to switch suppliers.

Can’t control Costs

One of the most popular reasons why manufacturers wish to change their suppliers is that their costs are growing. Now, it’s true that you have part inflation and labor costs going up. However, it’s important to differentiate costs that go up for this reason and price increases that are the result of other things, such as poor management. The supplier you choose should also be able to help cost down your product.

Poor Quality

Poor quality does not just negatively affect your profit, because you need to replace those bad parts/products. It also obstructs future growth. You might be able to grow a product that is expensive. However, you can’t grow a product that has consistent quality problems.

It’s also important to understand quality problems will always come up. However, your supplier needs to follow the proper steps in order to solve these quality problems.

Can not Scale Up

Another common yet unfortunate reason why manufacturers switch suppliers is that the supplier is unable to scale up production. What this means is that they are unable to grow with you. There are a number of reasons for this. The most common reason is that your supplier is not willing to make the financial commitment to help you scale up. And there is nothing wrong with this. Maybe this was something you should have asked when you originally evaluated your supplier or maybe you grew past your expectation.

Lack of Transparency & Communication

At the end of the day, a supplier will do anything to gain your business. However, once you agree to work with them, things change. One of the biggest changes you see is the change in how they communicate. Instead of being proactive they turn reactive and might make certain changes without telling you. Once you see these changes happening, it’s wise to move on.

How to Change Suppliers

The reason to change suppliers will dictate how you change suppliers. For example, if your supplier is lacking transparency then you will be more eager to switch quickly. However, if your supplier is unable to scale up then it might be more acceptable to have a longer transition between the two suppliers.

Here are the steps to change your supplier without negatively affecting your output.

Understand your Needs

You’re changing your supplier for a reason. You need to understand a bit better why you are changing your supplier. If there was something you did incorrectly during your original evaluation process then you need to alter the way you evaluate suppliers.

Do your Due Diligence

This is the best time to explore new options. This can be quite time-consuming but if you pick the right production partner then you will quickly see positive results.

Here are the steps you can take:

- Ask if anyone you know has a supplier reference.

- If you are sourcing a commoditized part, Alibaba will do just fine. Otherwise, stay away.

- Be transparent with your new suppliers. Changing suppliers can be a long process and your new suppliers will need to be patient.

- Visit them. This might be difficult to do if they are in China but there are third-party companies you can hire to audit a facility. Regardless, meeting face-to-face is usually helpful.

- Make sure you fully evaluate them. This can be a helpful supplier evaluation checklist.

- Learn from your mistakes.

Transfer Product Knoweldge

After the due diligence steps, you should know whether or not there is some potential to proceed. If it’s worth taking the next steps then you can send them your product data and share your files. The request for quote (RFQ) process is the point at which you share this data with your supplier. You should provide your supplier with the following:

- 2D & 3D Drawings

- Bill of Materials (BOM)

- A functional prototype

- Minimum order quantity (MOQ) and annual forecasts

- Target price

In return for sending them the product data, you will receive a quote. This quote will help dictate whether or not you want to proceed.

Prototype Process

If you accept their quote, it’s time for another test and this is the prototype process. The goal of the prototype process is to see whether or not they can replicate your product. While this is important it does not tell the entire story. Parts made for prototypes are made differently than in production and should not be the sole way to know whether or not your new supplier is capable of moving forward.

Where are you now?

The next step is to analyze your current position. After you have received quotes and prototypes from a few new suppliers, you need to make a decision if it’s worth launching production. Maybe you will find out that your current supplier is not so bad after all. Or the decision will be so obvious to change suppliers.

Pre-Production

If you move to this step, you are committed to changing suppliers or at least launching production with a backup supplier. There are six steps of pre-production that you must take:

- Confirm the contract

- Confirm any open or pending development activities

- Open tools and create any fixtures or jigs necessary for assembly or sub-assembly processes

- Create the golden sample

- Set up the production line with assembly instructions

Planning the Supplier Transition

During the previous steps to change your supplier, you will need to gauge production output closely. This is assuming you want to transfer production quickly. If you are looking to transfer production to a new supplier quickly then it’s very important to not rush any steps. Just because you switch suppliers does not mean your experience will be better.

Also, do not expect your new supplier to go into production at full scale on the first order. There is a lot of knowledge and experience your old supplier has gained through the years of making your product. It often takes multiple orders for your new supplier to be fully confident to reach the previous output of your old supplier.

With that being said, the transition is important. Fully pulling production out of your old supplier too quickly will put your output at risk. The best thing to do is to have a slow transition by gradually lowering orders from your current supplier and increasing order volumes to your new supplier.

How to get Started?

The way you manage your product data will impact the speed and efficiency with that you can change suppliers. If your product data is all over the place then the transition will take longer. However, if your product data is well organized then the time it takes to switch suppliers will be considerably shorter.

Before you start the RFQ process, you will need to ensure your product data is correct and up-to-date. Companies that adopt digital transformation are more likely to be able to have a smooth transition from one supplier to another because of data availability. This will also lead to better decision-making.

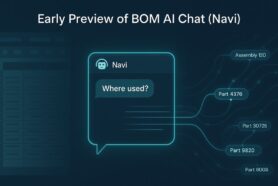

OpenBOM is a cloud-based PDM & PLM platform to manage your engineering and manufacturing data. Companies from startups to Fortune 500’s use OpenBOM to create a centralized database to bring in, store and manage their manufacturing data. With this infrastructure, users also use OpenBOM to streamline both their change management and PO processes.

If you need to improve the way you manage your data and processes, share data instantly, or collaborate with contractors and suppliers. contact us today for a free consultation.

Regards,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.