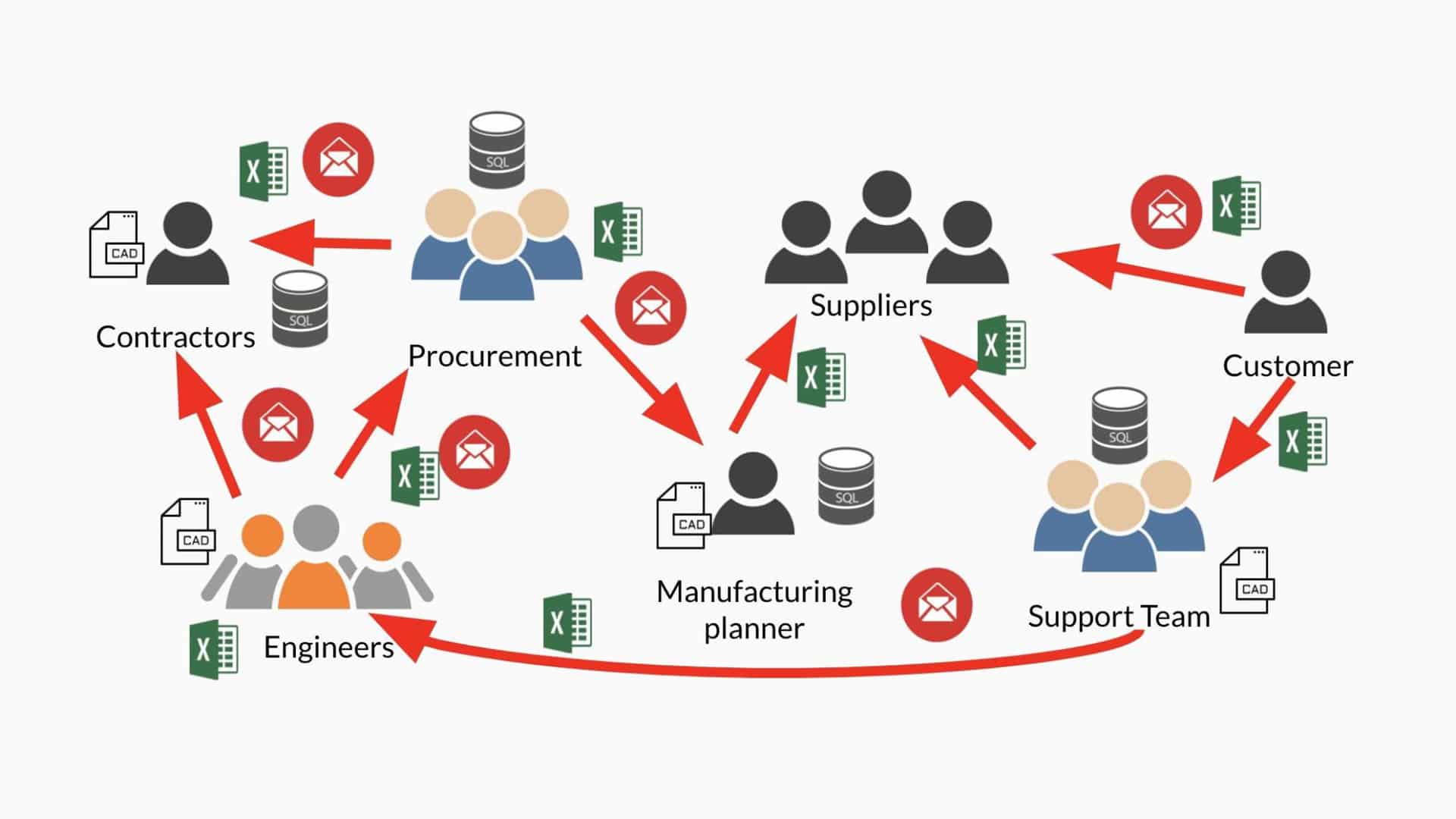

As technology advances, manufacturers are increasingly relying on data and communication for their day-to-day operations. Efficient data management is a foundation of successful operations and helps to streamline company processes. There is nothing more disrupting than searching for the right data, working on the wrong document, or sending incorrect information to a contractor or supplier. Today more than ever, there is an urgency in solving a problem to manage product data and coordinate product development and related activity.

Let’s face it, design alone cannot help you build a great product at the right cost and on time. Every company we’ve been talking to brings evidence that Excel (or another form of a spreadsheet) is part of the many processes and creates a lot of inefficiencies.

According to the State of Manufacturing report, 91% of manufacturers reported increased investment in data management and digital solutions across both operations and production to help enhance supply chain resiliency, accelerate product development, and deal with the multiple effects of the COVID-19 pandemic.

Therefore you need to bring online data management services to store and manage their data. By doing so, they can improve communication and collaboration among team members, as well as increase efficiency and productivity. In today’s post, we’ll discuss why now is the time for manufacturers to embrace online data management services. We’ll also explore the benefits of using such a service. Stay tuned!

Manufacturing and Digital Transformation

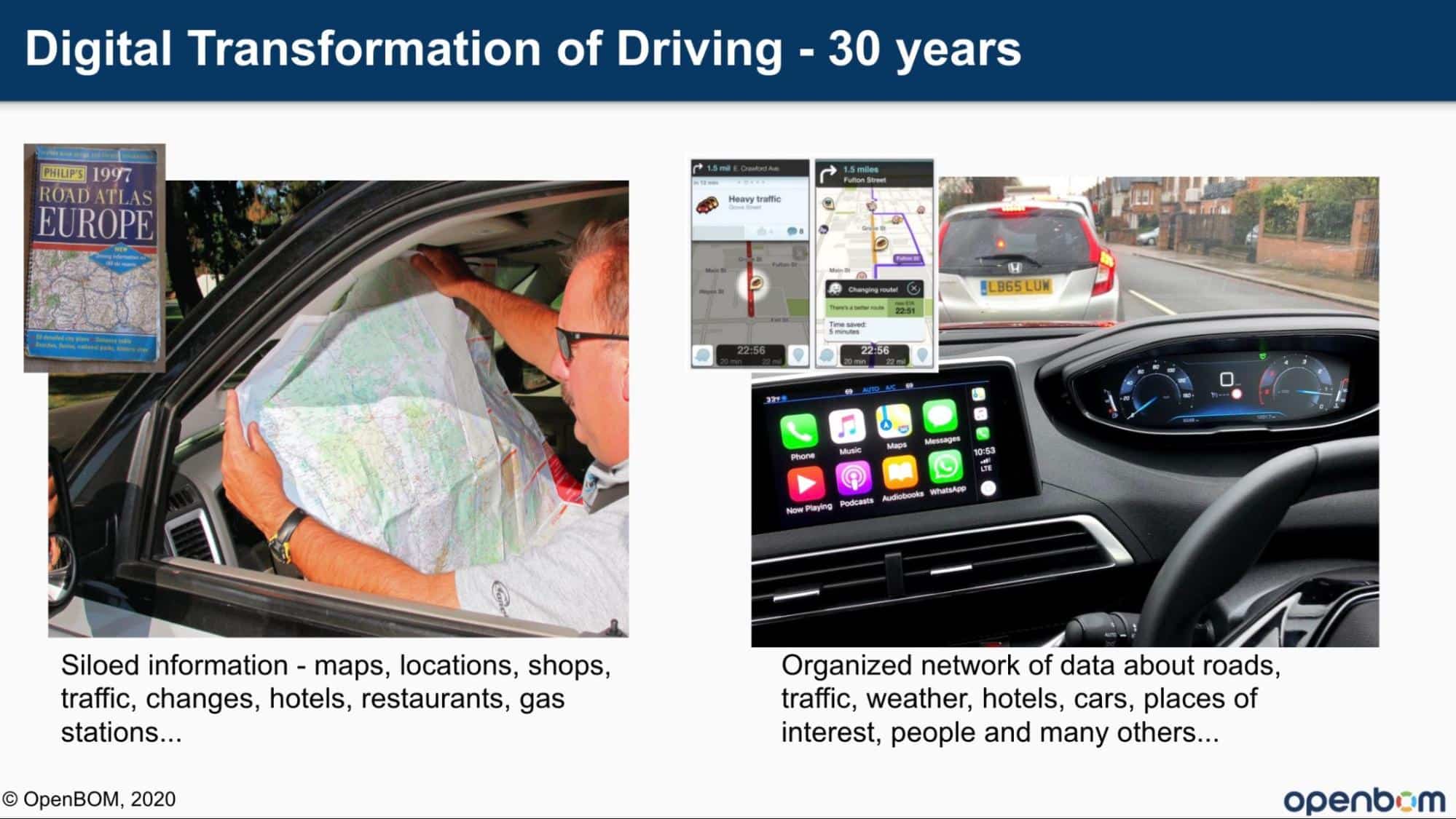

Digital transformation is a broad business strategy that includes the usage of technologies to transform traditional processes. Digital transformation in manufacturing allows you to impact multiple characteristics – to maximize revenues, reduce cost, improve quality, and increase flexibility. Digital transformation solves traditional business challenges and creates new opportunities using new technologies. You can see my favorite example of digital transformation in a driving process below.

However, digital transformation doesn’t come automatically. It requires the acceptance of new ways of working and delivering value to customers.

4 Reasons To Escape Excels

Excels (and other spreadsheets) are easy to start with but things can get messy very soon. Here are the top four reasons why Excels are a bad foundation of your data management system.

- Data silos and replication

- No structure and ability to manage assembly-component relationships

- There is no easy way to count usage and calculate the cost

- No granular revision control and change management mechanisms

Most of the organizations I’ve seen start with spreadsheets and later discover how inefficient they are. A usual excuse is that “at the current stage” Excel seems to be sufficient. But all these organizations will pay later on with mistakes, high cost, delayed and bad quality products.

How Online Data Management Services Can Help

In my earlier article – Top Pros And Cons Of Using Spreadsheets in BOM Management, I shared the main reasons why industrial companies should embrace online data management services such as cloud PLM and BOM management. These are 5 things you will be able to do differently by escaping Excels and starting to manage your data properly:

- Stop data isolation in silos and create a single source of truth for item data.

- Management of product structures and automatic quantity rollups across multiple assemblies.

- Use formulas and rollups to calculate various analytics (cost, mass roll-ups, etc.)

- Visual data (images and 3D previews).

- Instant data sharing and collaboration.

Altogether, these methods allow you to stop the data mess, accurate data representation, eliminating the need to copy/paste data and send multiple Excels via emails to different people in your organization as well as to contractors and suppliers.

Conclusion

When finding a better way to work, industrial companies choose a digital transformation journey to switch from outdated Excel-drive processes to modern digital methods and online data management tools. These tools help manage data and keep the right people, processes, and information connected and available to everyone.

OpenBOM provides an online service enabling engineers, contractors, and manufacturers to work together, manage information, changes and streamline their business processes. OpenBOM patented BOM collaboration methods allow you to share data instantly and to support simultaneous changes made by multiple team members while preserving history and managing revisions.

Register for free to use OpenBOM and start a 14-days free trial to learn more about all OpenBOM subscriptions and plans.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.